(1) Causes of deformation

When constructing small steel formworks, they cannot be placed in accordance with the specified settings, which will cause the overall performance of the building to decline. Then in the subsequent construction process, the building formwork will be deformed, which will affect the overall construction.

When the building formwork is placed, if the foundation is not stable enough, or it is not leveled, then it will cause the foundation to sink, the whole will be affected, and the construction will not be able to proceed.

(2) Solution

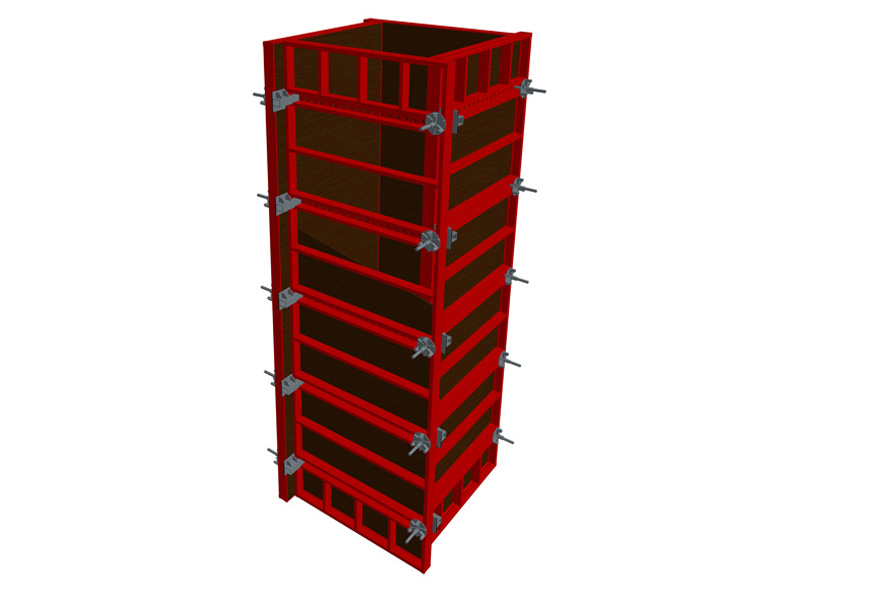

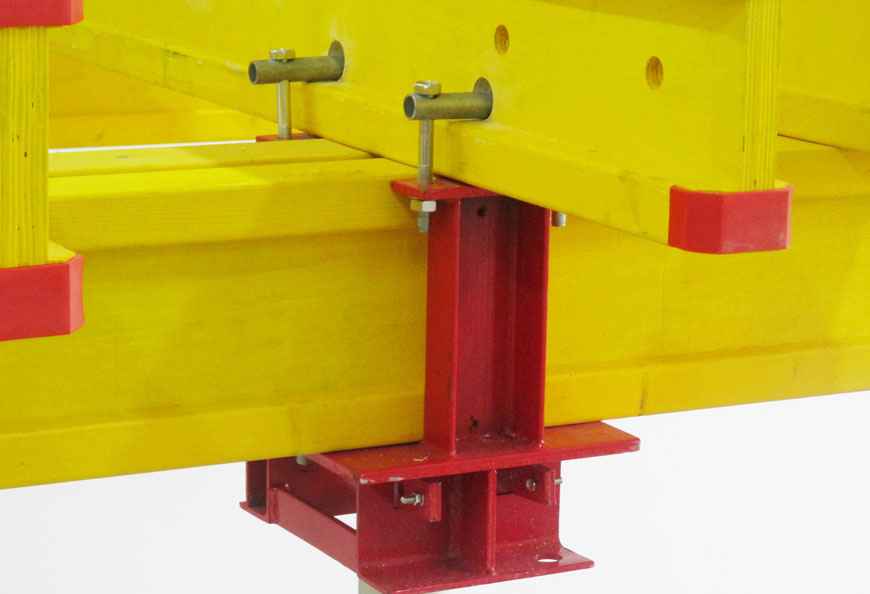

When combining small steel formworks, they should be placed in accordance with regulations, and the bolt spacing between the building formworks and specifications should meet the requirements, so that they can be used firmly and the construction can proceed normally. In terms of the support spacing at the bottom of the beam, it is necessary to ensure that it can support the corresponding load, so that it is impossible to deform during use.

(1) It is recommended that the edge cutting amount is less than 10% of the area of the building formwork. The smaller the edge cutting margin, the more beneficial to the utilization of wood. It is related to the size of the building formwork, the combination technology of the slab, the edge cutting technology, and the performance of the equipment.

(2) To ensure that the four corners of the building formwork are square, the four sides are straight, the edges should be smooth, without obvious saw marks, and the size should be within the allowable tolerance range after edge cutting. In general, the thicker the formwork, the lower the formwork feeding speed, the less the corners of the building formwork being cut. This should be based on the proficiency of the builders, who should grasp the scale.

(3) Common situations and adjustment and improvement methods in the process of building formwork cutting:

1) The saw cut is rough and uneven. It is necessary to reduce the feed speed, and check the installation method of the saw blade .

2) The edge is curved, and the pressure needs to be adjusted to check the saw cut and change the saw blade.

3) After sawing, the two sides are not parallel. You need to flatten the building formwork and then saw the edge. Stop the machine and check the saw position and make adjustment.

4) For clamping saw or burning saw, it is necessary to adjust the feeding speed, adjust the saw position, check the parallelism, and adopt the steaming and softening technology.

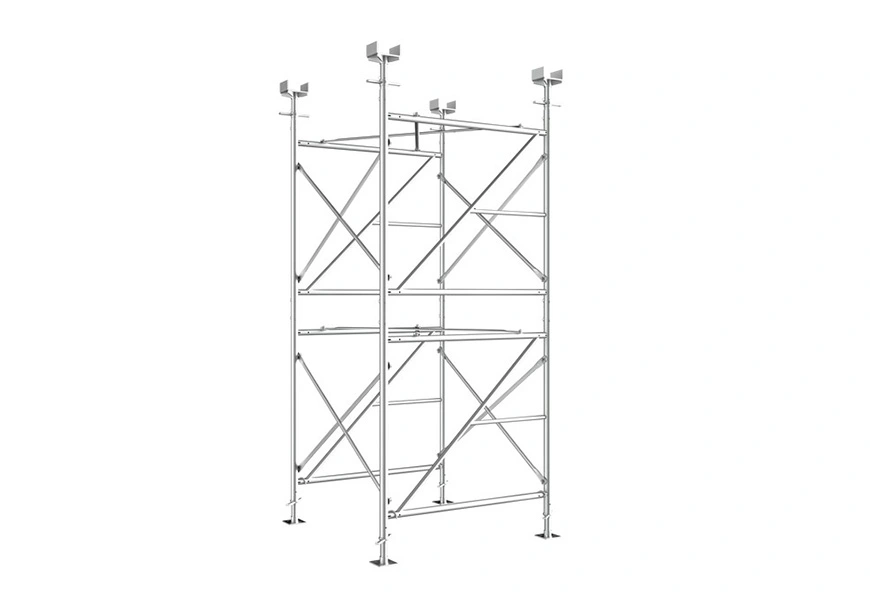

The above are the reasons and solutions of deformation of building formwork in the construction process and precautions about cutting. I hope it would be helpful. As one of the leading experts in the field of formwork and scaffolding systems engineering, Suzhou TECON Construction Technology Co., Ltd., has a wide range of ready-made and customized products so as to ensure that we can provide solutions for your construction projects, regardless of its scale or location. With the expertise of our R&D team, our technical team members will provide you with on-site assistance when necessary, and know that our solutions are always cost-effective. You can be sure that from the first contact to the completion of the construction, we are always there and support you. If necessary, please consult.