The new aluminum formwork has been widely applied in the current market, and the promotion and use of its products have become a trend. With the application of aluminum alloy formwork becoming more and more widespread and mature, the use of this product is becoming more standardized and standardized, and there is reliable evidence for construction and acceptance.

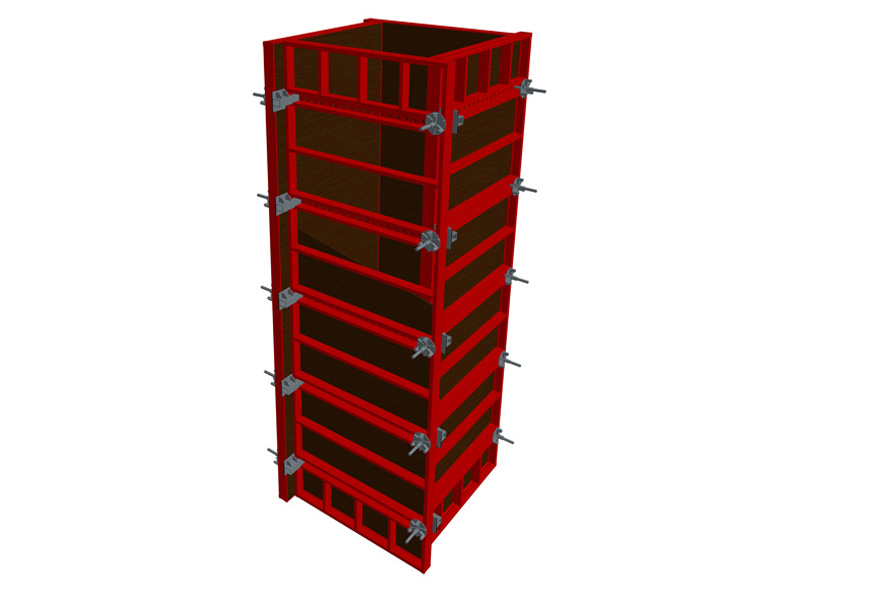

The new aluminum formwork system is generally designed and manufactured according to the module system. In the process of operation, its structure can be analyzed. It mainly includes three parts: aluminum panel, supporting frame and connecting parts, thus forming a universal accessory with complete matching use. It can be combined and assembled into a complex overall template with different dimensions. It is a system formwork for assembly and industrialized construction.

The aluminum panel directly contacts the load-bearing plate of newly poured concrete, including assembly panels and ribbed panels. According to the location of use, it can be divided into flat (including columns, shear walls, beams, floors, etc.) templates, yin-yang angle templates, connection angle templates, etc.

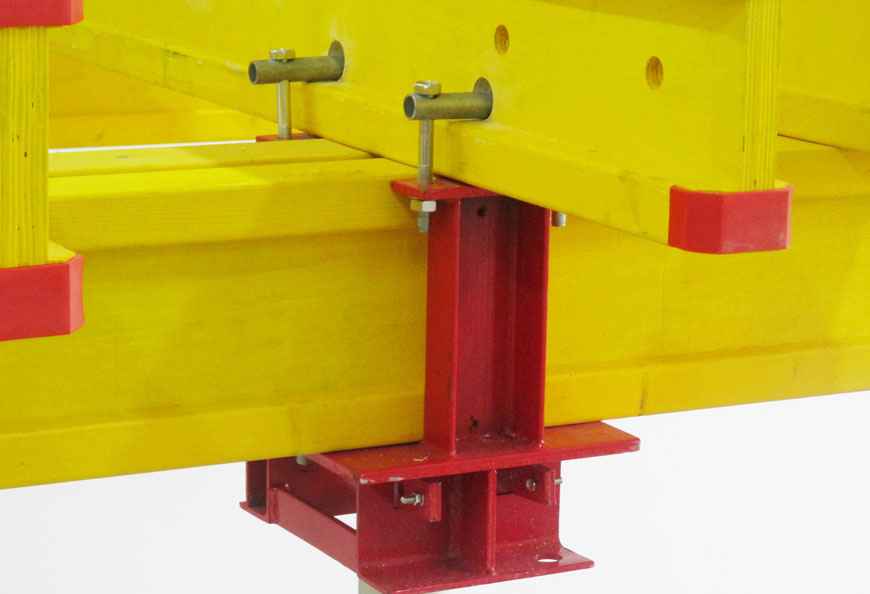

The support of the new building aluminum formwork mainly refers to the components used in the building aluminum formwork for connecting panels and top supports. The connection between the panel and the top support, the splicing of the panel itself, the connection of the reinforcement system and its accessories, including key pieces, bolts, back ribs, gaskets, and pull bolts. From the perspective of practical application, this product has many advantages, firstly, the construction period is greatly shortened, and construction and management costs are reduced.

The new aluminum formwork has a high turnover rate. Under the conditions of standardized construction, a set of formwork can be used more than 200 times. In practical construction, it is not only more convenient and efficient, but also the aluminum alloy formwork system is easy to assemble, and the width of the surface is about 400mm, with an average weight of about 25kg/m². It can be completely assembled manually without the assistance of mechanical equipment. Skilled installation workers can install 20m²/person-day, saving vertical transportation costs and unloading platforms.

The stability of the new building aluminum formwork is good, and the bearing capacity is high during operation, which can meet different requirements for its use. Its application range is becoming more and more extensive, suitable for all parts of general buildings such as columns, shear walls, beams, slabs, stairs, bay windows, construction columns, and scattered components.

Moreover, after demoulding, the concrete surface is smooth and flat, and the inspection indicators such as flatness, verticality, and squareness of yin and yang corners can generally exceed national standards, and it can basically meet the requirements of plain concrete and crude decoration without plastering. Putty can be applied directly after scraping.

As one of the leading experts in the field of formwork and scaffolding projects, our wide range of off-the-shelf and custom products ensure that we can provide solutions for your building project, no matter how large or small or wherever it is located. Please feel free to contact us for any inquiries.