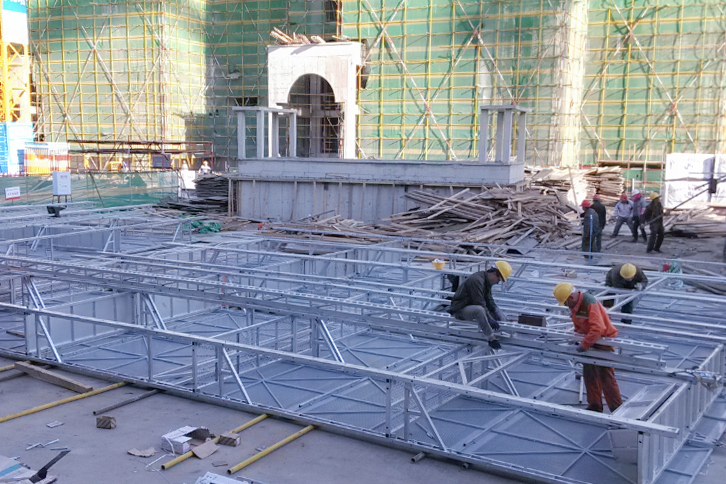

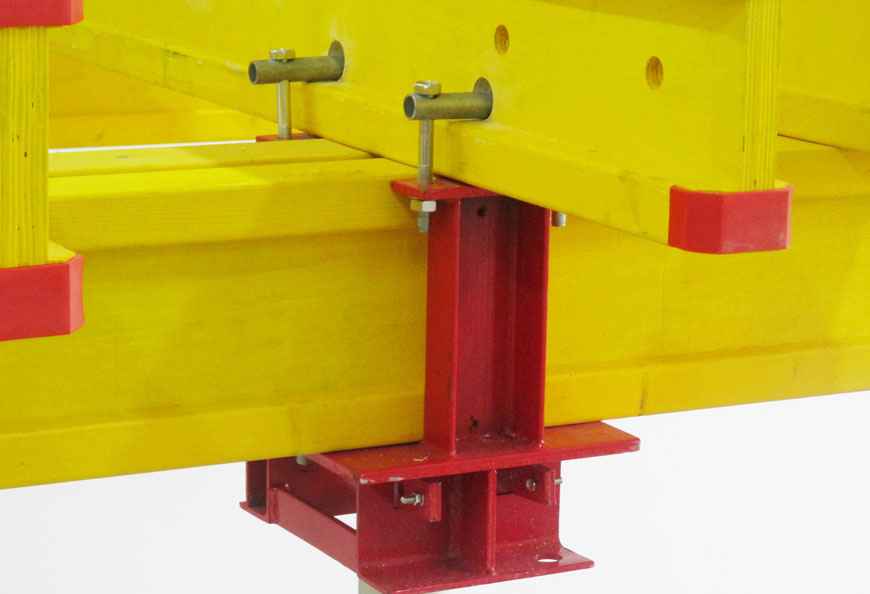

Check the reinforcement binding and acceptance, outer wall line and outer wall formwork of the first formwork in the warehouse-single-side support is installed on site, steel bars and installation pipes for single-side support bracing (additional steel pipes for the inclined bracing part of the single-side support, to be prepared on site) are installed- install pressure beam channel steel-install accessory system-adjust the verticality of the support-install operation platform and then tighten and check the installation system-pass acceptance and pouring of silicone, dismantle the bridge formwork for maintenance and repair.

Strictly control the concrete grading and control the temperature of the warehouse. Use vibration measures to improve the compactness of the concrete. Therefore, it is necessary to use mechanical joint operations, do a good job in construction organization, and ensure the quality of concrete construction.

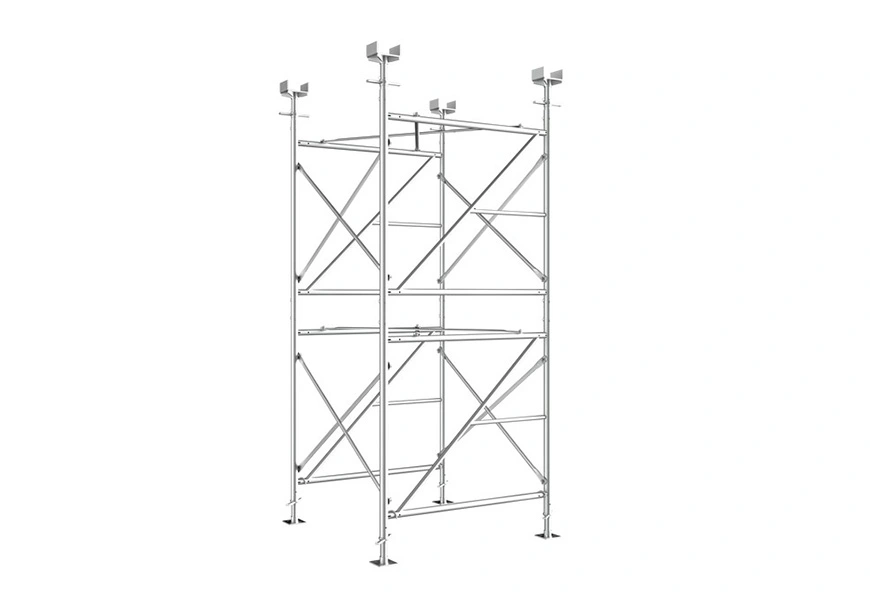

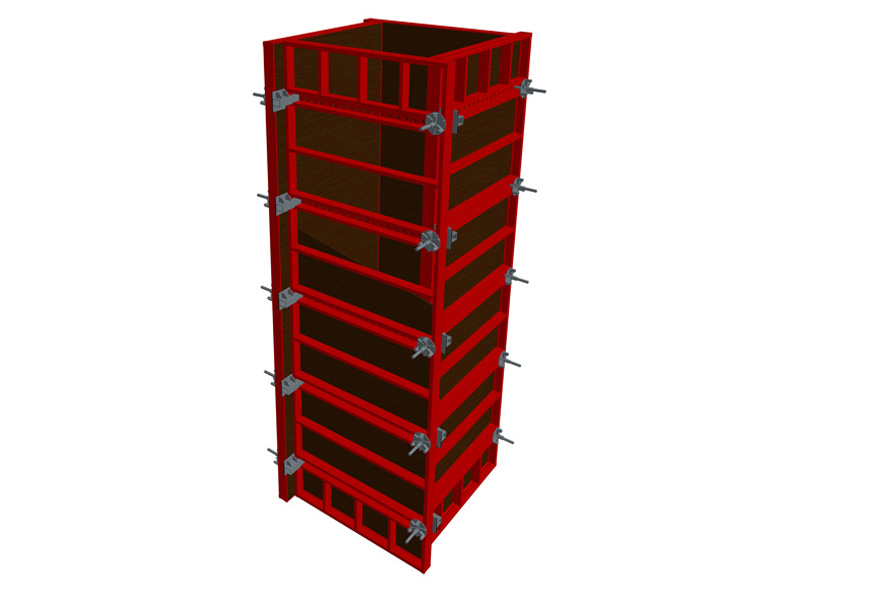

The concrete bridge formwork, including various concrete formwork types, should ensure the correct shape and size, flat and smooth panel, tight joints, and no leakage of slurry. The sufficient strength, stiffness, and stability ensure that deformation is within the allowable range.

Do not use waste engine oil or waste diesel as the release agent, nor use other release agents that are easy to adhere to the concrete surface or change the color of the concrete.

Before pouring concrete, the performance of the mixture must be tested. Control the temperature of the concrete entering. Mix the concrete with ice water at 5℃. When the temperature of the aggregate is lower than 32℃, the temperature of the concrete outlet can be controlled below 28.5℃.

Concrete pouring in warm season should be carried out when the temperature is low at night; concrete pouring in low temperature season should be carried out on days with small temperature changes.

During the vibration process, technical personnel should be dispatched to observe and record the concrete vibration time and the radius of the vibration rod in order to adjust and improve the vibration process and prevent over-vibration or leakage during the vibration process. The vibration sequence of the plug-in vibrator should start from the place closest to the bridge formwork, first the outside and then the inside, and the moving distance should not be greater than 1.5 times the effective vibration radius of the vibrator. The distance between the plug-in vibrator and the bridge formwork should not be greater than half of the effective radius of the vibrator, and collisions with steel bars, bridge formwork, core pipes, inflatable capsules, and various bottles should be avoided as much as possible.

With the professional knowledge of TECON's research and development team from our formwork company, we will provide you with assistance on-site when necessary, and know that our solutions are always cost-effective. You can rest assured that from the first contact to the completion of construction, we are always there to support you. Welcome to inquire.