The casting process is a process in which liquid metal is poured into a mold to set and cool, and the common concrete casting formwork for bridges is made using the casting process. Not only the casting process, common processing processes are as follows:

Mainly zinc alloy casting (cold mold, plastic mold, rubber mold), low melting point alloy (cold mold, plastic mold), Shaw casting method, beryllium copper casting and synthetic resin casting and other methods of casting zinc alloy mold.

Mainly applicable to a variety of mold processing, precision cutting machine processing, replica milling machine processing, replica machine processing, molding grinder processing, engraving machine, molding machine and CNC machine processing methods, according to the processing of mold parts precision requirements to achieve, the cutting process is further divided into roughing process, finishing process and refining process.

Roughing process, the so-called roughing process is the process of cutting most of the excess material from the workpiece in the steel formwork processing, so that its shape and size close to the requirements of the finished product. Such as rough turning, rough boring, rough milling, rough planing and drilling, etc., machining accuracy below IT11, surface roughness Ra6.3μm, rough machining is mainly used for low processing requirements, or non-surface matching and as a fine pretreatment before the steel formwork processing treatment.

Finishing process to cut off the rough surface of the excess material, in order to achieve high precision machining. The common processing methods are mainly finishing turning, finishing boring, reaming, grinding holes, electric machining and profile grinding.

Everyone refining process, refurbishing process is to clean a small amount of excess material from the surface of the finished workpiece to obtain a higher precision and surface quality parts. This steel formwork process is usually the tail step of parts processing, its precision and surface quality are required to be higher and should meet the requirements of steel formwork processing mold design drawings, such as grinding of guide pillar and guide sleeve, polishing of work forming parts, etc.

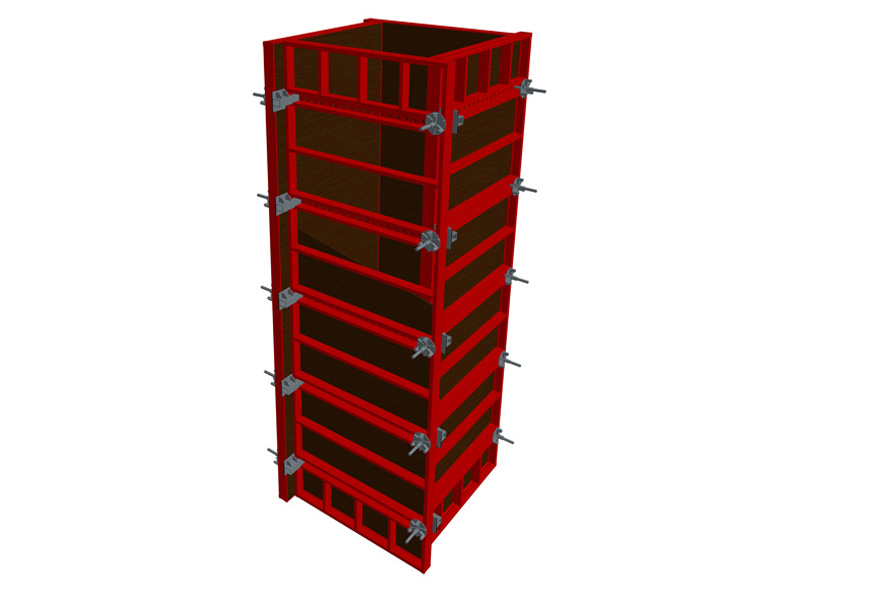

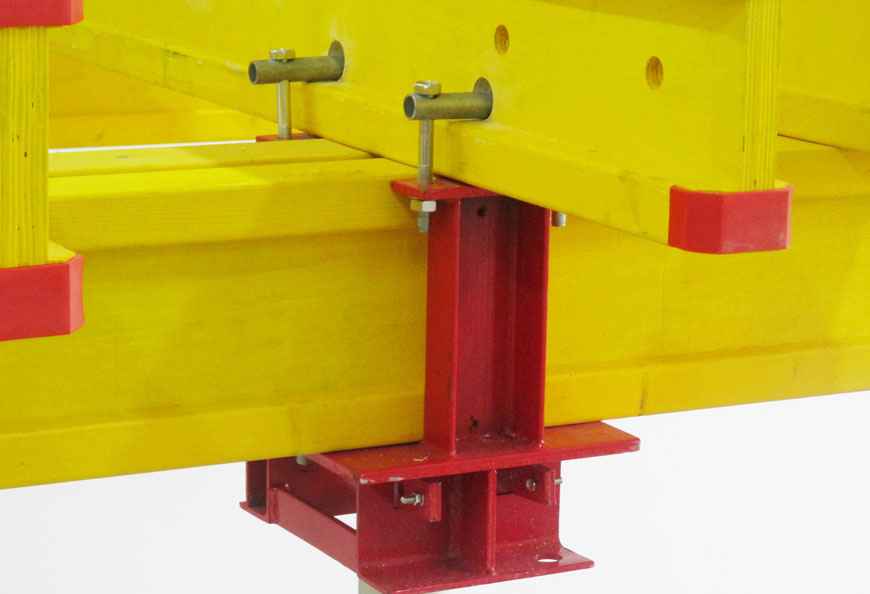

Our company, as one of the leading experts in formwork and scaffolding engineering, our wide range of off-the-shelf and customized products ensures that we can provide solutions for your construction projects, regardless of size or location.

With the expertise of our R&D team, our technical team members on site to assist you when necessary and knowing that our solutions are always cost effective, you can rest assured that we are always there to support you from first contact to construction completion. Feel free to ask questions.