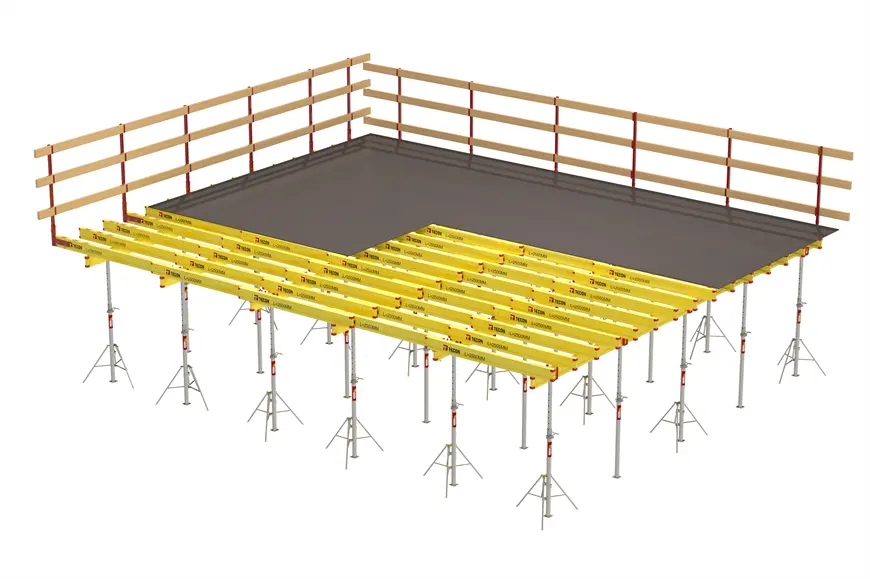

The bridge formwork is a structural part specially used for the construction of railway or highway bridges. It is a temporary supporting structure. It must be made according to the design requirements, so that the concrete structure and components can be formed according to the specified position and geometric size, and the correct position can be maintained. Withstand the self-weight of the formwork and the external loads acting on it.

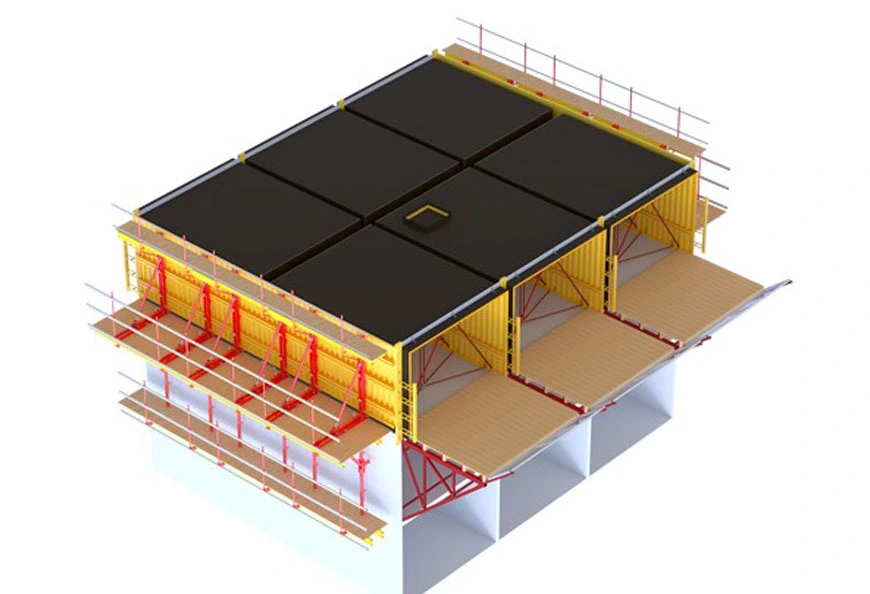

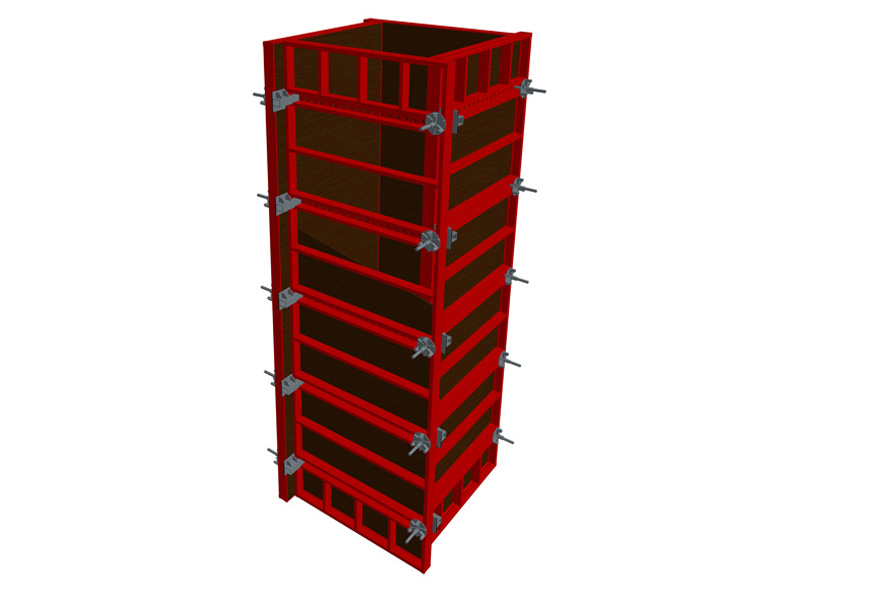

For the construction of cast-in-place reinforced concrete structures with bridge steel formwork, large-scale formwork for beams and columns can be assembled in advance according to the design requirements, and the method of dismantling in bulk can be adopted.

Bridge formwork is widely used in construction projects. It is a temporary support structure and needs to be made according to the design requirements, so that the concrete structure and components can be formed according to the specified position and geometric size, maintain their correct position, and withstand the dead weight of the building formwork and External loads acting on it.

Due to the lack of timber resources in China, driven by the policy of "replacing wood with steel", China has successfully developed advanced construction technology for bridge steel formwork, reformed the formwork construction process, and saved a lot of wood.

China's building structure system has developed greatly, with a large number of high-rise buildings, super high-rise buildings and large public buildings being built, large-scale infrastructure construction, and the rapid development of urban transportation, expressways and railways. A new request was made.

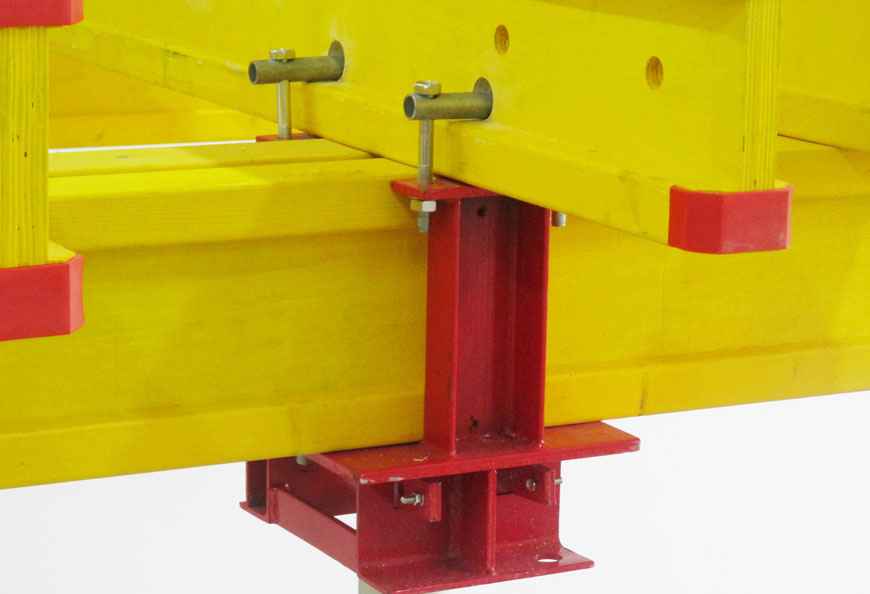

When the bridge formwork is assembled, the connecting parts should be placed according to the regulations, and the spacing and specifications of the purlins and the tension bolts should be set according to the design requirements. When designing the building formwork and support system, its own weight, construction load and concrete weight and the lateral pressure generated during pouring and tamping should be fully considered to ensure that the building formwork and support have sufficient bearing capacity, stiffness and stability.

As one of the leading experts in formwork and scaffolding engineering, our wide range of off-the-shelf and bespoke products ensures that we can provide a solution for your construction project, no matter the size or location.

With the expertise of our R&D team, our technical team members on-site to assist you when necessary, and knowing that our solutions are always cost-effective, you can rest assured that from first contact to construction completion, we are all Always there to support you. Welcome to consult.