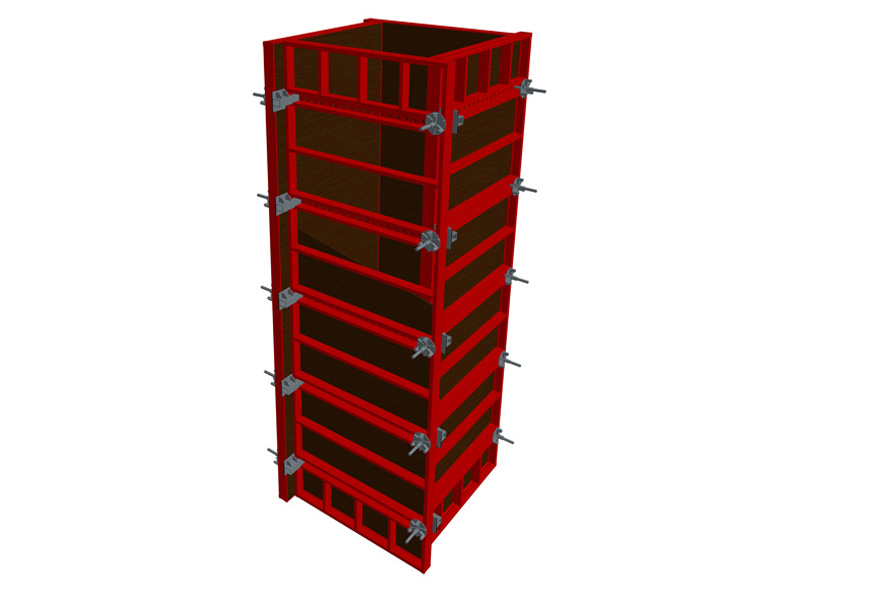

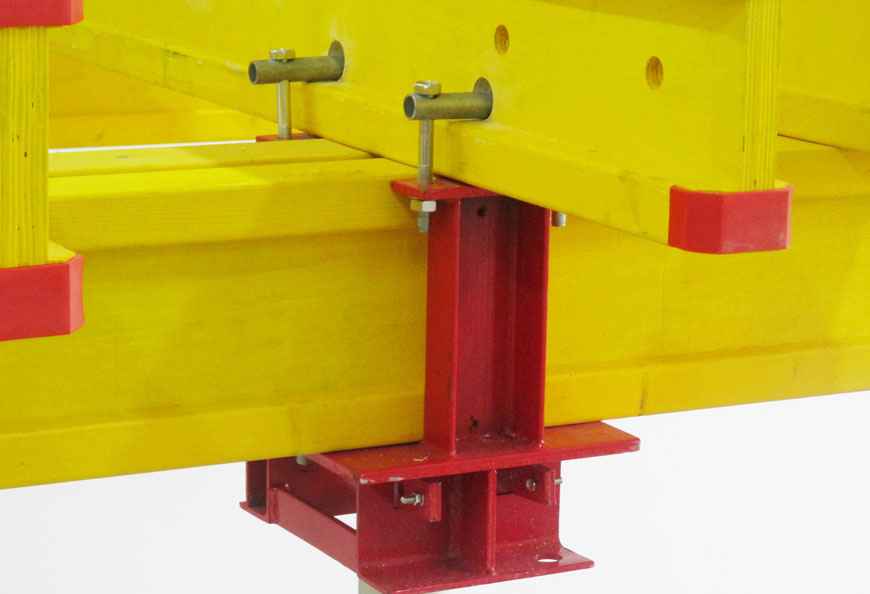

aluminium formwork is a building formwork made of aluminum alloy, also known as aluminum alloy formwork. It has a complete set of general accessories for use, and can be assembled into integral formwork with complex dimensions of different sizes. The system formwork for assembly and industrial construction solves the defects of traditional formwork in the past and greatly improves the construction efficiency.

1. The aluminium formwork technology does not require the assistance of mechanical equipment during construction, and only needs to manually splicing and installing the aluminium formwork, which reflects the characteristics of convenient operation.

2. The aluminium formwork has a strong load-bearing capacity. Compared with the general formwork, it can withstand more pressure, which provides a guarantee for the stability of the building, thereby reducing the occurrence of potential safety hazards during the construction process.

3. aluminium formwork is widely used, and its construction does not have too many conditions. After the splicing is completed, the gap at the joint is small and the application rate is high. Simplicity and invulnerability to reuse.

1. Technical aspects: The use of 3D technology can convert buildings and structures drawn from traditional two-dimensional planes into three-dimensional models, express and communicate visually, discover design errors in advance, and reduce unnecessary changes and rework.

2. In terms of progress: using aluminum molds for 3 days/layer, and using wooden molds for 5-6 days/layer, the progress is faster and the cost is effectively controlled.

3. Management: the use of aluminium formwork management personnel is reduced by half compared with the traditional formwork, and the process management is less simple than the traditional wooden formwork, which promotes scientific construction and refined management.

4. In terms of quality: the top plate is flat, the yin and yang corners are square, the walls are vertical, and the beams are straight.

5. Safety aspects: the vertical transportation of the upper and lower transfer formwork has less safety hazards, and avoids the safety risk in the process of using the unloading platform, reducing the safety risk of tower crane transportation.

6. Civilized construction: the use of aluminium formwork to remove the formwork, less construction waste, easy floor cleaning, civilized construction standards, environmental protection and resource conservation.

7. Indirect costs: The rental and management costs of accessories and machinery are reduced accordingly, thereby improving economic benefits.

The materials used in traditional formwork construction are usually disposable materials, which do not conform to the modern concept of saving resources and increase the cost. Compared with traditional construction, aluminium formwork technology has the characteristics of being reusable. In essence, it saves resources, and can also be applied in high-rise buildings, even in the construction of complex environments. aluminium formwork construction technology can effectively improve construction efficiency, ensure construction quality, and improve the accuracy of construction projects. Instead of being eco-friendly, it plays a role in construction and ensures the standards and quality of construction projects.