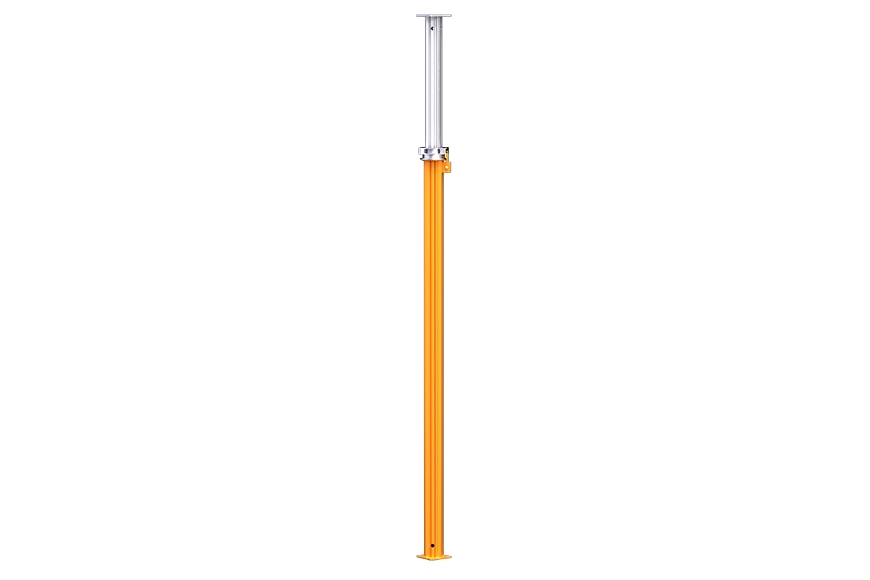

TECON Scaffold Ringlock is designed and manufactured as the most convenient and efficient scaffolding system. It only consists of a few user-friendly components and a hammer. It can be used as a shoring system, facade platform, and work access in any residential, commerical and civil engineering projects.

Quick erection and dismantling with only a hammer

Safety and stability due to rigid wedge connections without loosening

Durability and less maintenance due to high strength steel and hot-dip galvanizing finishing.

It can be used as an access tower with stairs inside to the site at the height

It can be used as shoring support to meet heavy load requirements

It can be used as a façade platform for site crew protection and a working platform at the height.

| Parameter | Specification |

| Connection Design | Eight holes on each rosette allow various tight connectionsfrom the ledger to the diagonal brace |

| Surface Treatment | Minimum 60µm hot-dipped galvanization |

| Main sizes of Standard | 0.5/1/1.5/2/2.5/3 m |

| Miximum Height | 24 m |

| High Strength Grade Steel Material | Q345 with O.D.48*3.2mm |

| Alternative Diameter | 60 mm diameter standard is also available |

| Application of Ringlock Scaffolding | Construction sites from residential & commercial buildingsto flyover roads, metro stations, ship yards, petrochemical plants and others. |

You can send us your material list to request a quotation, or you can also simply send us the structural drawing and project information for complete formwork & scaffolding proposal via the below contacts.

Email: info@teconform.com

Phone: +86-512-65650586

Mobile: +86-13862020161.

By T/T or L/C.

For climbing formwork, self-climbing platform, plastic formwork, we have stock in our warehouse. The preparation of loading will be within 10 to 15 days.

For H20 timber beam, TECON-Form Shuttering, the lead time is from 15 to 25 days.

For other systems, the lead time is from 30 to 45 days.

For a more accurate lead time, don't hesitate to contact us for a specific product based on your quantity.