To span a bridge is to transform knowledge into experience. TECON is firmly committed to maintaining its leadership in formwork technology. This commitment drives us to continuously develop bridge formwork solutions that enhance construction efficiency and implement them systematically.

TECON bridge formwork solutions are always offered as comprehensive packages that deliver tangible benefits and added value to our customers. With a client-oriented mindset, we ‘build bridges’ to help our customers achieve their goals.

The automatic climbing formwork handles significant variations in the design of piers and pylons, regardless of geometry, height, and dimension.

TECON provides cost-effective and on-time delivery of material-optimized shoring scaffolds, ensuring the safe and economical transfer of high loads from the upper structure of the bridge.

TECON’s all-in-one system offers excellent cost-effectiveness and rapid equipment availability, making it a reliable choice for various construction needs.

Our long-term collaboration with leading beam equipment suppliers enhances project-specific planning and pre-assembly of high-performance molding systems. This partnership ensures smooth and efficient construction schedules, contributing to the overall success of your projects.

As soon as we get the structural drawings of your bridge project, whether for a bridge pier, pylon or box girder, our team will submit corresponding formwork and scaffolding systems solutions to you on a cost-saving basis.

Bridge shuttering material refers to the temporary formwork or mold used to create the shape and size of bridge components during construction. It is typically made of wood, steel, or other durable materials and is designed to support the weight of the wet concrete until it sets and hardens.

The choice of shuttering material depends on several factors, including the size and shape of the bridge components, the complexity of the design, and the desired finish of the final product. Common shuttering materials used in bridge construction include timber, plywood, steel, and precast concrete. Timber is often used for its ease of handling and flexibility, plywood provides a smooth finish and added strength, steel is known for its durability and reusability, and precast concrete is ideal for creating repetitive elements with high quality and consistency.

In addition to providing structural support for the wet concrete, shuttering material can also help to create the desired surface finish and texture of the bridge components. Once the concrete has set, the shuttering material is removed to reveal the final product. Proper selection and installation of the shuttering material are critical to ensuring the finished bridge’s structural integrity and aesthetic appeal. By carefully choosing the appropriate shuttering material and ensuring its correct installation, construction teams can achieve the desired outcomes in terms of both structural performance and visual appearance.

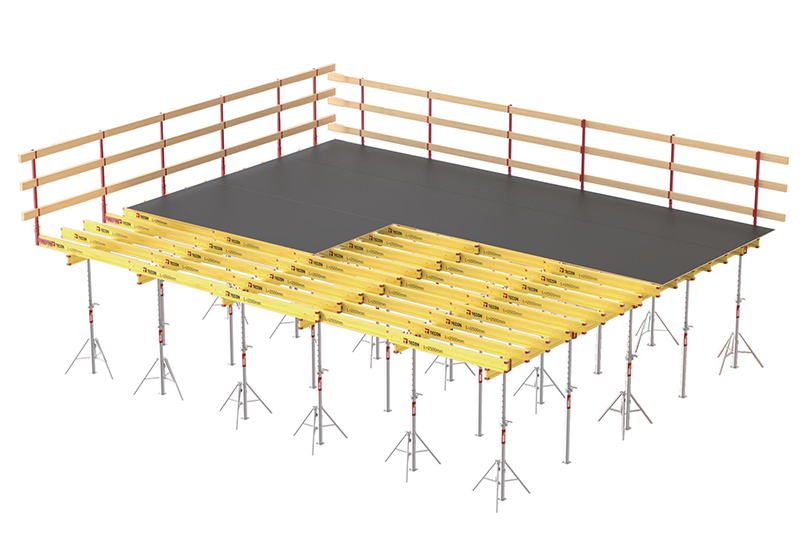

Bridge formwork design involves creating a temporary structure to support the weight of wet concrete during the construction of a bridge deck. The formwork provides the shape and contour for the finished deck and allows for the placement of reinforcement steel.

The design of bridge formwork must consider several factors, such as the shape and size of the bridge deck, the load capacity of the supporting structure, and the requirements for concrete placement and finishing. The design should also account for safety measures, such as fall protection and access for workers.

The choice of formwork materials will depend on specific design requirements and may include steel, aluminum, or wood. The formwork must be able to withstand the weight of the wet concrete and any additional loads that may be imposed during construction.

Bridge formwork design is a complex process that requires a team of experienced engineers and construction professionals to ensure that the formwork is safe, efficient, and meets all design specifications.