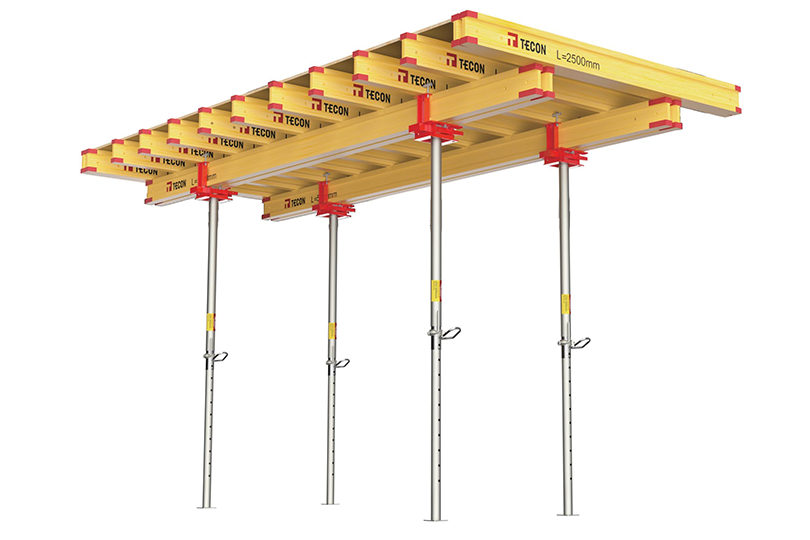

Kwikstage scaffolding is a type of modular scaffolding system commonly used in construction projects. It's known for its versatility, ease of assembly, and robustness. The system consists of pre-fabricated components including standards (vertical tubes), ledgers (horizontal tubes), transoms (diagonal tubes), and steel scaffold boards.

Flexibility: Kwikstage scaffolding can be easily adjusted and adapted to suit various job site requirements.

Safety: Its robust construction and secure locking mechanisms ensure stability and minimize the risk of accidents.

Efficiency: The system's simplicity and ease of assembly contribute to increased efficiency on job sites. With fewer components and straightforward connections, workers can erect and dismantle Kwikstage scaffolding quickly, saving time and labor costs.

Versatility: Kwikstage scaffolding can be used for a wide range of applications beyond simple access platforms. It's suitable for supporting formwork, providing temporary roofs, and constructing loading bays, among other uses.

Durability: Made from high-quality steel, Kwikstage scaffolding is built to withstand harsh weather conditions and heavy loads.

Transport and Storage: Kwikstage scaffolding components are designed for easy transportation and storage. They can be stacked compactly when not in use, minimizing space requirements on-site and during transportation.

Compatibility: Kwikstage scaffolding components are often compatible with other scaffolding systems, allowing for integration or expansion of existing setups. This compatibility enhances the system's flexibility and usability, especially in complex construction environments.

You can send us your material list to request a quotation, or you can also simply send us the structural drawing and project information for complete formwork & scaffolding proposal via the below contacts.

Email: info@teconform.com

Phone: +86-512-65650586

Mobile: +86-13862020161.

By T/T or L/C.

For climbing formwork, self-climbing platform, plastic formwork, we have stock in our warehouse. The preparation of loading will be within 10 to 15 days.

For H20 timber beam, TECON-Form Shuttering, the lead time is from 15 to 25 days.

For other systems, the lead time is from 30 to 45 days.

For a more accurate lead time, don't hesitate to contact us for a specific product based on your quantity.