In the process of installing the bridge formwork, we should pay attention to the following safety measures.

1. Wear a safety helmet to check whether the tools used are firm before work. Tools such as wrenches must be hung on the body with ropes and chains to prevent them from falling and hurting people. When working, workers should concentrate and avoid nails piercing their feet and slipping in the air.

2. When installing and dismantling the bridge formwork of more than 5 meters, formwork scaffolding should be set up, and protective railings should be set up. It is forbidden to operate on the same vertical surface and it is required to fasten seat belts when working at high places.

3. Do not pile large batches of materials such as templates on the formwork scaffolding.

4. The wires and electric tools used on the bridge formwork should adopt a 36V low-voltage power supply or take other effective safety measures.

5. During ascend operations, various accessories should be placed in a toolbox or tool bag, and are strictly prohibited from being placed on a template or bridge scaffolding; Various tools should be hung on the operator or placed in the tool bag and must not be dropped.

6. Operators working high above the ground are strictly forbidden to climb up and down the combined formwork or scaffolding, and are not allowed to walk on the top of the wall and the formwork at high altitude.

7. The reserved holes of the template should be covered or a protective fence should be set up with a safety net at the entrance of the hole.

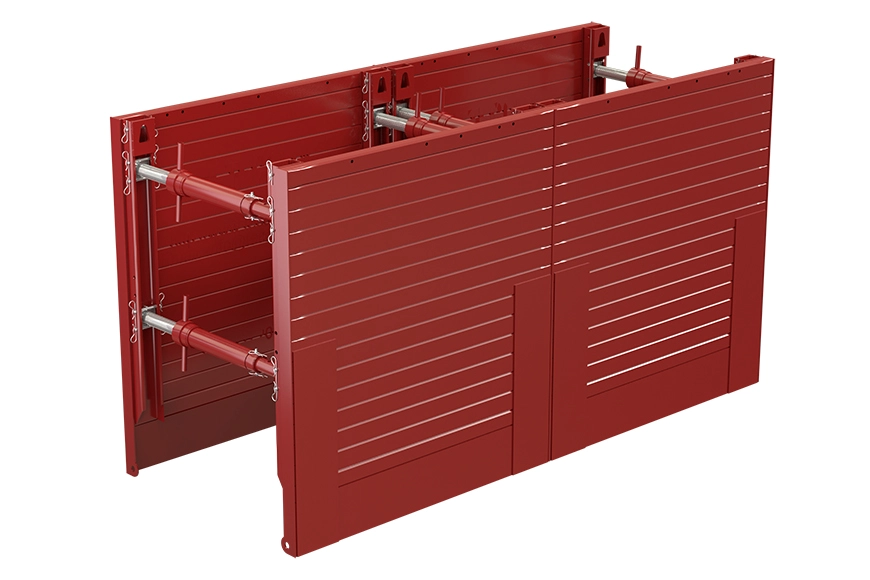

8. When assembling and disassembling the steel formwork of the bridge, there should be someone coming to the operator's aid. They should help each other, and the movable parts should be fixed firmly, and it is strictly forbidden to stack or throw them on the scaffolding board.

9. When assembling and disassembling the steel formwork of the bridge, a stable climbing tool must be used. When the height exceeds 3.5 meters, scaffolding must be erected. When assembling and disassembling, no one can stand below except the operator. When working at high places, the operator should put on a safety belt.

10. The sequence and method of bridge formwork removal should be carried out in accordance with the provisions of the design of the supporting board, and operators should follow the principle of supporting first and then dismantling, and the principle of first non-load-bearing parts, then load-bearing parts and the top-down principle. It is strictly forbidden to hit or pry hard with a sledgehammer when disassembling the formwork.