When it comes to pipeline construction, one critical aspect that demands attention is the safety and stability of the excavation trenches. Trenches are dug to accommodate pipelines, and to ensure the protection of workers and the prevention of soil collapse, the use of trench boxes has become essential. In this article, we will explore the application of trench boxes in pipeline groove support, highlighting their significance and the benefits they offer in ensuring a secure construction environment.

Trench boxes, also known as trench shields or trench shoring systems, are temporary protective structures designed to support the walls of an excavation trench. They are typically made of steel and consist of two parallel sidewalls connected by cross members. The primary purpose of a trench box is to prevent soil collapse and provide a safe working environment for construction workers inside the trench.

Worker Safety

Pipeline construction often involves working in deep and narrow trenches, which can pose significant risks to workers. Trench boxes play a vital role in ensuring worker safety by providing a stable and protected workspace. They help to prevent soil movements and potential collapses, reducing the risk of accidents and injuries caused by cave-ins.

Soil Stability

Excavation trenches can be susceptible to soil movements and instability, particularly in loose or unstable soil conditions. Trench boxes provide structural support to the trench walls, preventing them from caving in and maintaining the stability of the excavation. This ensures that the pipeline groove remains intact and protected throughout the construction process.

Preparing the Excavation Site

Before installing the trench box, proper preparation of the excavation site is necessary. The trench should be carefully excavated to the required dimensions, ensuring that it accommodates the pipeline and provides sufficient space for the trench box installation. Any loose or unstable soil should be removed or stabilized.

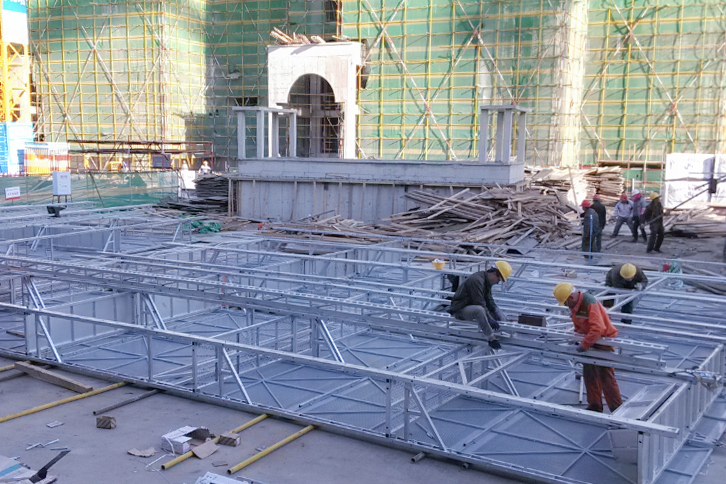

Installing the Trench Box

Once the excavation site is prepared, the trench box can be installed. The trench box is typically placed inside the trench, with the sidewalls positioned parallel to the trench walls. It should be securely positioned to prevent any movement or displacement during the construction process.

Backfilling and Compaction

After the trench box is installed, backfilling and compaction can be carried out. The excavated soil is carefully placed and compacted around the trench box, providing additional support to the sidewalls. Proper compaction techniques should be employed to ensure the stability and integrity of the backfilled soil.

Enhanced Construction Efficiency

The use of trench boxes in pipeline groove support can significantly enhance construction efficiency. By providing a safe and stable working environment, construction workers can carry out their tasks more efficiently without the fear of cave-ins or soil movements. This leads to improved productivity and a smoother construction process.

Cost Savings

The implementation of trench boxes can result in cost savings for pipeline construction projects. By preventing soil collapse and associated delays, the use of trench boxes minimizes the need for costly re-excavation and rework. It also reduces the potential for accidents and injuries, thereby mitigating potential legal and medical expenses.

Compliance with Safety Regulations

Trench boxes are an essential tool for ensuring compliance with safety regulations in pipeline construction. Occupational Safety and Health Administration (OSHA) guidelines and other industry standards often require the use of protective systems, such as trench boxes, to provide a safe working environment in excavations. By utilizing trench boxes, construction projects can adhere to these regulations and promote a culture of safety.