Composition and characteristics of steel formwork

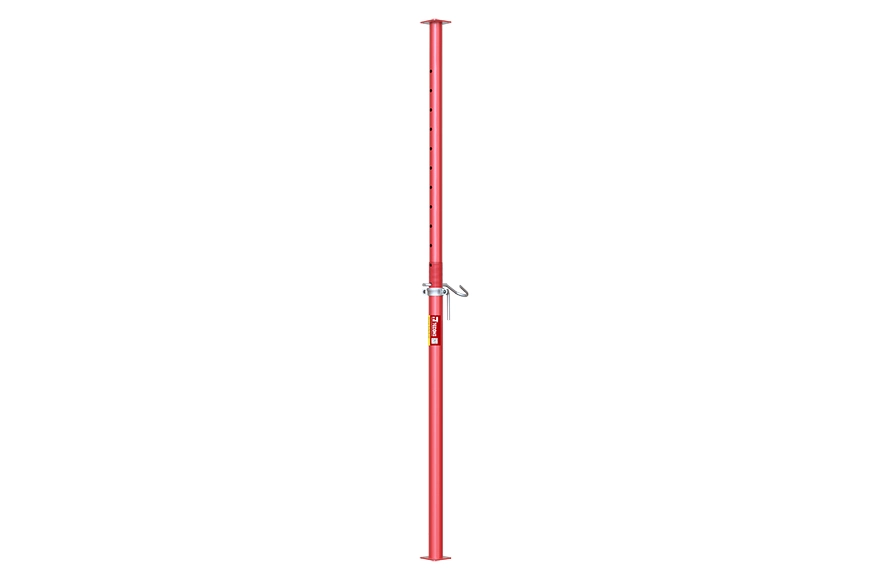

Steel formwork is composed of plate structure, support system, operating platform, and accessories. It is a tool formwork used for the construction of cast-in-place walls and wall structures.

The feature of steel formwork is that the size of the large formwork is the interval, depth, and floor height of the building.

Classification of steel formwork

According to the shape of the bridge steel formwork pouring, it can be divided into: box beam formwork, T-beam formwork, cover beam formwork, hollow beam formwork, circular formwork, protection beam formwork, pier column head formwork, etc.

Advantages of steel formwork

Enhance the system, high component strength, high combined stiffness, high plate production accuracy, tight joints, not easy to deform, steel formwork integrity is good, and seismic resistance is strong.

Steel formwork should be stored indoors as much as possible or placed in sheds on site. If stored in an outdoor place, use canvas or iron sheet to cover the formwork frames for sale, such as steel formwork frames, to prevent rusting of the steel formwork.

Whether it is in a warehouse or at a construction site, steel formwork should be neatly stacked according to specifications and cannot be placed at will.

It is recommended to apply rust-proof oil on the surface of the steel formwork and concrete when storing the steel formwork. If the paint on the back is partially peeled off, it should be repainted.

Before installing the bridge steel formwork, a release agent should be used. The installation bottom surface of the vertical formwork should be flat, clean, and reliable positioning measures should be taken. When using steel formwork in high-rise buildings, lightning protection facilities should be provided. When installing and dismantling the template, there must be stable climbing tools or scaffolding, and the operator should wear a safety belt when working at height.

It is recommended not to mix different specifications of formwork when transporting steel formwork. According to the pre-assembled formwork structure, size, and transportation conditions, it can be transported horizontally layered or vertically grid.

As one of the leading experts in the field of formwork and scaffolding engineering, our extensive range of ready-made and customized products ensures that we can provide solutions for your building projects, regardless of size or location.

With the professional knowledge of our R&D team, our technical team members are available on-site to assist you as needed, and we know that our solutions are always cost-effective. You can rest assured that from the first contact to the completion of construction, we will always be there to support you. Feel free to contact us.