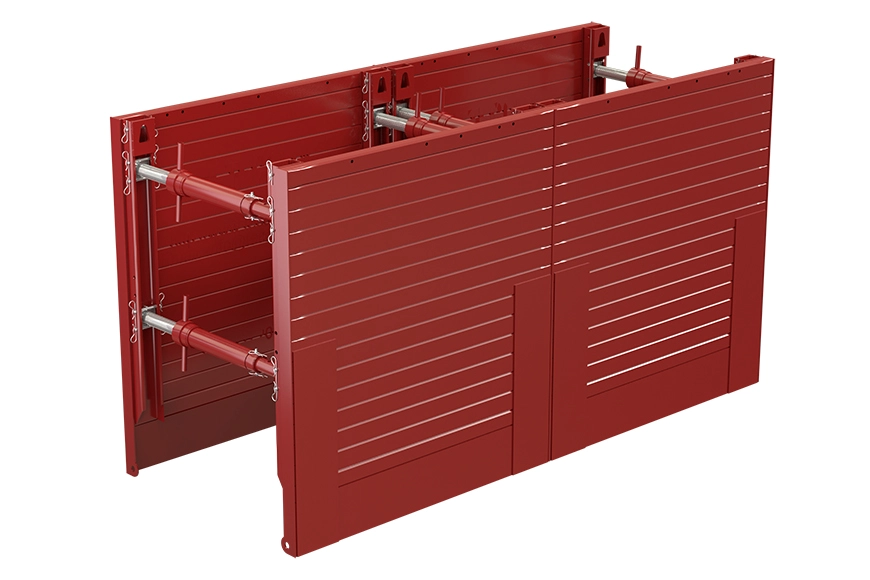

The bridge formwork, as its name suggests, is a steel formwork used in bridge projects, such as highway bridges, elevated bridges, and overpasses. The house building formwork is used in civil construction such as factories, workshops, offices, and residential buildings.

With the development of industrialization in construction and the continuous improvement of bridge formwork technology, the promotion and application of bridge formworks has also been continuously improved. However, a series of problems should be noted when using the bridge formwork. Especially after the construction is completed, the following items should be checked:

Collecting, collating, and checking the data of the bridge formwork in the construction site;

Checking whether the support is rusted, aged, moved, etc;

Checking whether the pier and foundation slide or tilt. Whether the concrete cap has weathered, cracked, peeled, or exposed bars. Whether the top of the pier is clean and whether the expansion joints leak. Whether the conical slope is intact and whether there is any delamination or loss of hook joints or cut blocks, and whether there is a through crack.

Checking whether the concrete is cracked or damaged, and whether the steel reinforcement is corroded. Whether there is an overall cracking phenomenon caused by alkali aggregate reaction. Whether there is severe carbonization on the surface, and whether there is obvious displacement and deformation of the beams.

Checking whether the bridge formwork is flat, straight, and free to extend and contract, and whether there are abnormal deformations, noises, looseness, damage, shedding, leaks, and whether foreign objects are embedded. Whether the groove paving layer has nibbling and whether it causes obvious derailment.

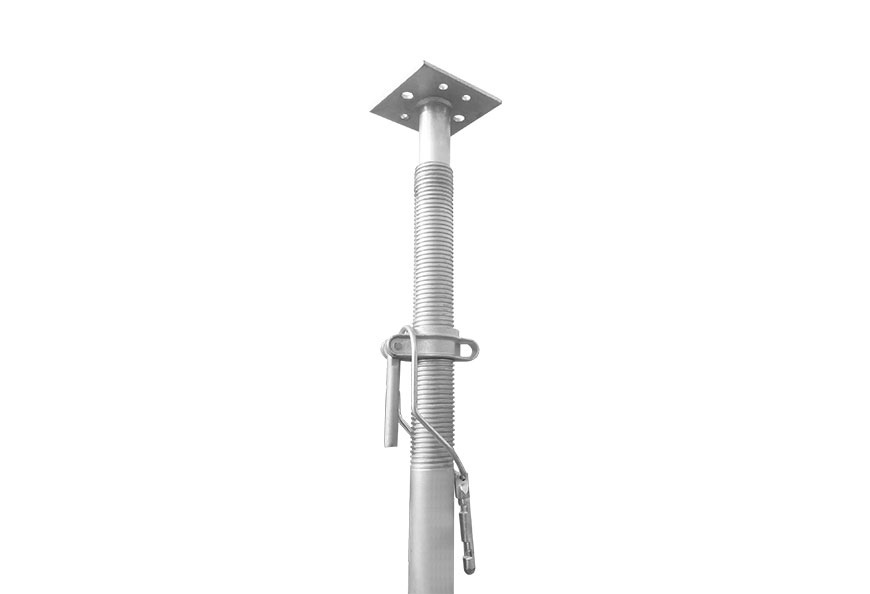

The use of construction formwork accessories, including bridge formwork accessories and formwork supports, is an important measure to replace wood with steel and a significant reform in concrete construction technology.

The bridge formwork must comply with four basic principles during the production process: rationality, practicality, economy, and standardization. The following introduces these four basic principles in detail.

Rationality

Consider whether the pouring process is applicable and can achieve the quality requirements in practical use, and pay attention to the following:

The compressive strength of the steel formwork should be sufficient and not lower than 2-3 times the actual bending strength;

Minimize the number of joints, and wherever possible, use large-sized formworks to reduce the amount of on-site assembly and disassembly work and facilitate fast construction;

When designing the connection of the steel formwork, a certain number of positioning pins should be set, which is conducive to controlling the stagger of the bridge formwork joints;

To prevent grouting, the connection part of the two formworks should be designed as an overlapping form.

Practicality

When designing, it is necessary to consider factors such as transportation convenience, ease of disassembly, site working environment, and construction conditions for ease of use.

Economy

When designing and calculating bridge formworks, under the premise of ensuring sufficient rigidity and strength of the formwork, reasonable selection of materials is necessary. Do not blindly adopt conservative design measures, which increase costs.

Standardization

Although the shapes and sizes of various structures are different, as the task volume increases and the variety increases, they can still be classified according to the main cross-sectional shape, longitudinal shape, and size range, and using a combination of standard and matching formworks to meet the size requirements and achieve construction objectives, reduce the investment in formworks.

This requires that the main raw materials used in this type of bridge steel formwork, the thickness of the steel plate, the thickness of the reinforcement plate, the spacing of the reinforcement plate, the hole spacing, and the hole edge distance are relatively fixed.

Our company is one of the professional formwork manufacturers specializing in bridge formworks, with guaranteed product quality and affordable prices, and we welcome inquiries.