After the installation and reinforcement of the formwork for the pier of the bridge, the total station is used to lay out the position of the pier and then the steel bars for the pier of the bridge formwork are embedded according to the construction design drawing.

In order to prevent the horizontal and vertical movement of the steel bars in the pier of the bridge formwork, two layers of fixed hoops are set up, with the lower fixed hoop being welded on the upper mesh reinforcement of the abutment and the top fixed hoop being set up 2 meters above the abutment top surface. The fixed hoop needs to be accurately positioned and welded to the embedded steel bars and the abutment surface reinforcement. To prevent the sinking of the pre-embedded steel bars in the pier of the bridge formwork, all the abutment stand-reinforcing bars within the range of the pier of the bridge formwork are welded to the upper and lower main reinforcing bars of the abutment, which have a supporting effect.

During the construction of the steel bars in the pier of the bridge formwork, the centerline of the pier is pulled out with two cotton threads according to the pre-set axis position, and the upper fixed hoop is adjusted and fixed according to the cotton thread. The pre-embedded steel bars in the pier of the bridge formwork are tied and positioned on the top steel mesh according to the painted line. If the top steel reinforcing bars are not in that position, a reinforcing bar is placed on the top steel mesh and welded to the pre-embedded steel bars in the pier of the bridge formwork to bear the weight of the pre-embedded steel bars.

During the process of pre-embedding the steel bars of the pier in the bridge formwork, the correctness of the verticality of the steel bars must be ensured;

The joints of the pre-embedded steel bars should be avoided within the range of 3 meters above the top surface of the abutment. When positioning the steel bars in the pier of the bridge formwork, the position of the tie rod should be staggered to avoid the tie rod being unable to penetrate in the future;

Curing of high-performance concrete.

In the construction of high-performance concrete, the curing work is an essential part that requires the use of a reliable and efficient concrete formwork system. After the completion of the highway bridge, appropriate moisturizing and insulation curing of the highway pavement is required. The commonly used method is to cover it with a film. For large components such as prefabricated box beams, low-temperature steam can be used for necessary curing.

In addition, special attention should be paid to the necessary watering of high-performance concrete after initial solidification to achieve the purpose of curing, so as to ensure that its quality and performance meet the requirements of curing.

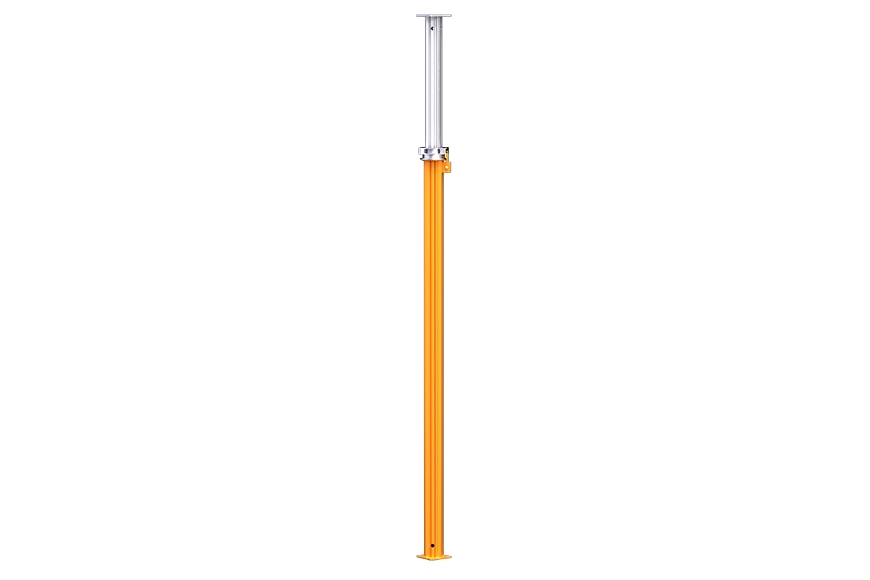

As one of the leading experts in the field of formwork and scaffolding engineering, our company's extensive range of ready-made and customized products ensures that we can provide solutions for your construction projects, no matter how large or small or wherever they may be located. Welcome to consult us.