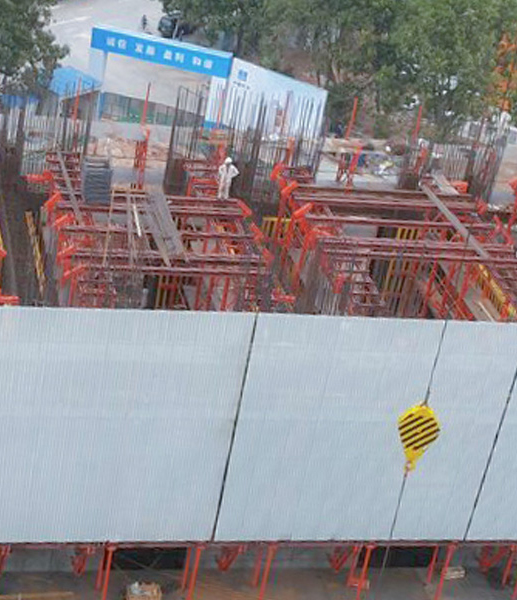

Slab shuttering is an indispensable component in construction, playing a crucial role throughout the entire building process. It is not only used to support the pouring of concrete but also impacts the overall quality, efficiency, and cost of a construction project.

High Strength and Durability

The primary characteristic of slab shuttering is its high strength and durability. The formwork needs to withstand significant pressure during the pouring of concrete, so materials with high strength and long-lasting durability must be chosen. Common materials used for slab shuttering include steel, aluminum alloy, and high-strength wooden formwork. These materials effectively ensure the stability of the formwork under high-pressure conditions, thereby reducing the likelihood of accidents during construction.

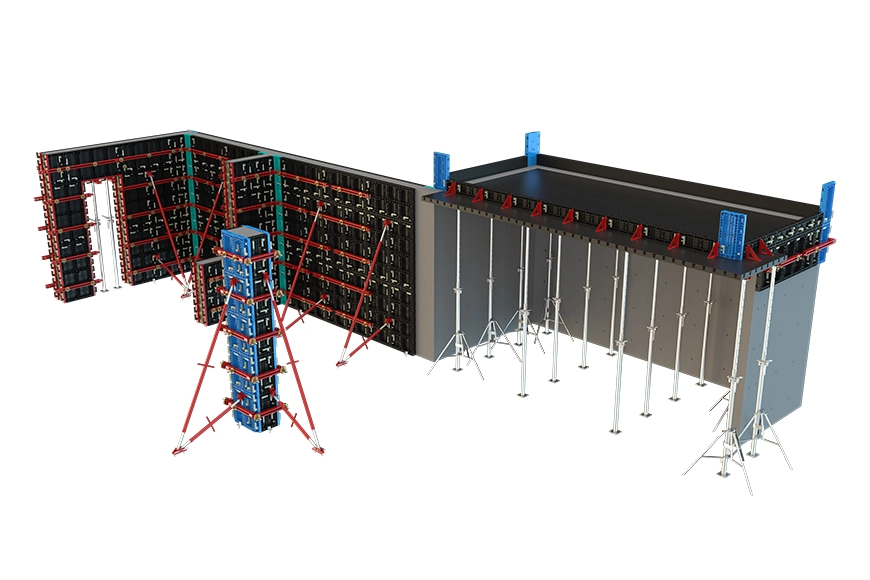

Convenient Installation and Dismantling

Slab shuttering systems are typically designed to be convenient and efficient for installation and dismantling. In modern construction, modular designs make the installation process even more straightforward. Workers only need to secure each formwork unit according to the system's requirements to complete the entire slab shuttering setup. This efficient installation and dismantling process not only saves time but also improves the overall efficiency of the construction site.

Superior Resistance to Deformation

During construction, slab shuttering must bear a substantial amount of pressure, and avoiding deformation is crucial to ensuring the quality of the project. High-quality slab shuttering has excellent resistance to deformation, effectively preventing issues such as uneven slab thickness or concrete cracks caused by formwork distortion. Moreover, its resistance to deformation ensures that the surface of the slab remains smooth, thereby improving the overall quality of the slab.

Reusability, Cost Savings

Another significant advantage of slab shuttering is its reusability. Many modern slab shuttering systems are made from high-quality materials, allowing them to be reused across multiple projects. This not only reduces material waste but also significantly lowers the overall cost of construction projects. This cost-saving benefit is especially important in high-rise or large-scale projects.

Precise Dimensional Control

High-quality slab shuttering ensures precise control over the dimensions of the slab after the concrete is poured. The shuttering system is typically crafted to meet the specific dimensions of the slab as per the design requirements, ensuring that every piece of formwork meets the project's standards. This precise control of dimensions helps to eliminate errors during the pouring process, ensuring the structural strength and safety of the slab.

In conclusion, slab shuttering is not merely a supporting tool in construction—it directly influences the quality, efficiency, and cost of a project. From high strength and durability to easy installation, resistance to deformation, and environmental benefits, slab shuttering systems undoubtedly provide efficient, safe, and sustainable solutions for modern construction. Therefore, selecting the right slab shuttering system is crucial for improving construction quality and reducing costs.