In the construction industry, aluminium formwork has gained immense popularity due to its versatility, durability, and time-saving benefits. It revolutionises the traditional formwork method by providing a more efficient and cost-effective solution for concrete construction projects. In this article, we will delve into the different types of aluminium formwork systems, highlighting their unique features and advantages. By understanding these variations, you can make an informed decision about the most suitable formwork type for your specific project needs.

Traditional aluminium formwork is the most commonly used type and serves as the foundation for other variations. It comprises robust aluminium frames and panels that are interconnected to create temporary molds for concrete placement. This type of formwork is highly adaptable and can be customized to accommodate various structural designs and dimensions. Traditional aluminium formwork offers excellent reusability, making it a cost-effective choice for projects with repetitive construction requirements.

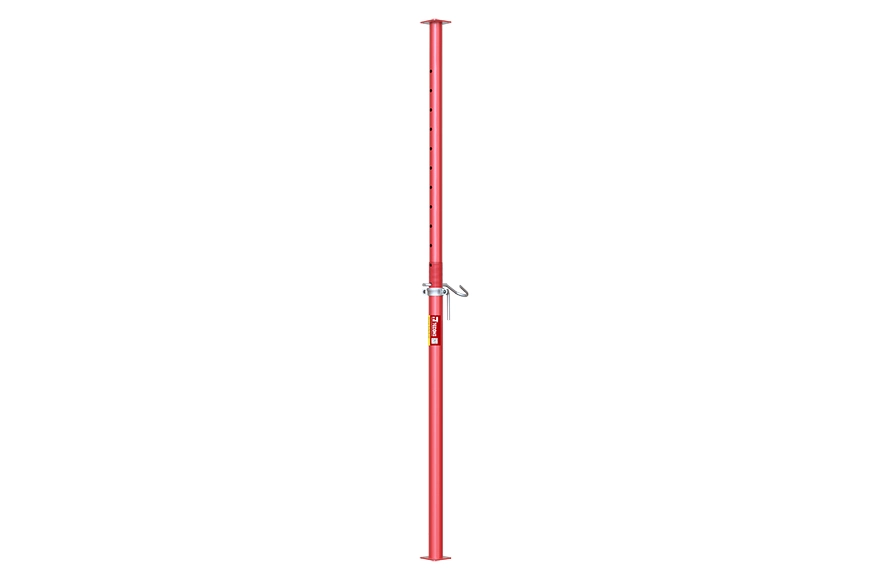

Engineered aluminium formwork takes the concept of traditional formwork a step further by incorporating precision engineering and advanced design techniques. It consists of prefabricated panels, beams, and props that are manufactured with utmost accuracy to ensure seamless assembly and superior structural integrity. Engineered aluminium formwork provides exceptional dimensional accuracy and consistency, resulting in high-quality concrete finishes. This type of formwork is suitable for complex construction projects that demand precise specifications and tight tolerances.

Modular aluminium formwork is a versatile and time-saving option that offers a systematic approach to construction. It consists of standardized panels, frames, and accessories that can be easily assembled and disassembled. The modular design allows for quick formwork installation, enabling faster construction progress. Additionally, the uniformity of the system ensures consistency in the structural elements and concrete finishes. Modular aluminium formwork is suitable for projects with repetitive layouts, such as residential buildings, where speed and efficiency are of utmost importance.

Climbing aluminium formwork is specifically designed for tall structures and vertical construction projects. It allows for the incremental construction of high-rise buildings without the need for external scaffolding. The formwork system is mounted on climbing brackets, which are hydraulically or mechanically lifted as the construction progresses. This method offers significant time and cost savings by eliminating the need for external support structures and reducing labour requirements. Climbing aluminium formwork ensures the smooth and efficient construction of vertical elements, such as walls and cores, in tall buildings.

Tunnel formwork is a specialized type of aluminium formwork used for the construction of repetitive structures, such as residential housing units or hotel rooms. It comprises a series of interconnected panels and bulkheads that form a tunnel-like structure. The formwork is moved horizontally along the building length, allowing for the simultaneous casting of walls, floors, and ceilings. Tunnel formwork ensures speedy construction, excellent structural integrity, and consistent finishes. This method is particularly suitable for projects that require rapid construction completion and standardized units.

Aluminium formwork systems have revolutionized the construction industry by offering efficient, durable, and cost-effective solutions for concrete construction projects. The various types of aluminium formwork, including traditional formwork, engineered formwork, modular formwork, climbing formwork, and tunnel formwork, cater to different project requirements and construction complexities. Each type offers its own unique advantages in terms of reusability, precision, speed, and adaptability. By considering the specific needs of your project, you can select the most suitable aluminium formwork system to optimize construction efficiency and achieve high-quality results.