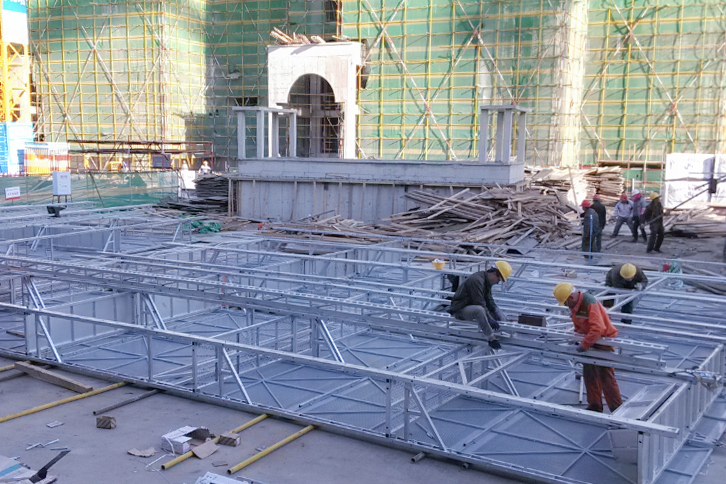

At present, bridge formwork adopts advanced formwork technology, which is of great significance to improving project quality, speeding up construction progress, improving labor productivity, reducing project cost and realizing civilized construction. However, the production and installation of bridge formwork must meet the following requirements:

1. The joints of the formwork should not leak grout.

2. The formwork must have sufficient bearing capacity and stability, and can reliably withstand the self-weight and lateral pressure of the cast-in-place, as well as the load generated during construction, and carefully consider unforeseen unfavorable factors in the construction process.

3. The bridge formwork and its supports should be regularly maintained, and the formwork and steel supports should pay attention to rust prevention. Unqualified fasteners should not be used. If the formwork is set up on the bottom layer, the base soil must be compacted and backed up, and the settlement surface of the base soil must not be used. It will cause the deformation of the support, thereby affecting the construction quality of the bridge formwork.

4. Ensure that the shape, size, elevation, axis and mutual position of each part of the engineering structure and components are correct, and meet the design requirements and specifications.

5. The bridge formwork is simple in structure, convenient in assembly and disassembly, and convenient for the binding of steel bars and the requirements for pouring and maintenance of concrete.

Note: The installation of the formwork should be reasonably selected according to the site conditions. During the installation process, anti-overturning measures must be set to ensure construction safety. After the installation of the bridge formwork is completed, the contractor shall check its plane position, top elevation, joint connection, and vertical and horizontal stability. In the process of concrete pouring, the observation of formwork deformation should be strengthened, and measures should be taken immediately to correct if it is found that the allowable value is exceeded.

For the construction of bridge formwork, such as bridge deck formwork, standardization is the key to determining the quality of the whole project, so we must pay attention to ensuring the processing of every detail when we carry out this link. Even if there is a slight deviation, you should pay attention to what are the requirements?

The design of prefabricated beam formwork, hanging basket formwork, tunnel two-lined trolley formwork, selection of production unit, trial assembly and acceptance, and first-piece experiment must be reported to the Superintendent's Office for approval before implementation.

All bridge formwork must be approved by the resident supervisor before entering the site: the processing unit is qualified, and the assembly and inspection are qualified. Any deformed or unqualified stitching, and those with uneven exposed surfaces will be removed from the venue.

During construction, we must use large-surface steel formwork to reduce joints. The height of each section of column pier and solid pier formwork shall not be less than 4 meters, and the plane formwork of the wall body shall not be less than 2*1.5 meters. The rigidity of the formwork must be ensured, and the formwork will not deform during the service period, and the use of tie rods as little as possible for the prefabricated beam formwork and the pier body and pier cap formwork.

The overall cast-in-place structural formwork supports and brackets must be specially designed, and a third-party qualified design unit shall review the calculation results and report to the project design unit for confirmation before implementation.

In short, when carrying out the construction of bridge formwork, we must pay attention to the above-mentioned contents, and every small difference can affect the quality of the whole project.