Bridge formwork, including formwork boards for sale or other types of formwork systems, is usually made of three or five layers of boards, which are all manually manufactured and inevitably have joints in the production process. In order to make the products more durable and of higher quality, four requirements must be put forward for their craftsmanship.

When the cross section of the member is accurate according to the compressive area at the joint, supporting pads made of steel or hard wood should be used for clamping.

It is not advisable to set toothed joints at the point where the wood is subjected to shear force. When toothed joints are necessary, the joint length should not be less than 0 cm, and the possibility of cracking of the wood due to dryness should be taken into account.

Steel clamping plates should be applied at the support (arch) bracket node and clamped with bolts.

Saw-toothed nails can only be used as temporary joints or reinforcement joints that are not considered under stress.

Construction preparation: Based on construction requirements, prepare construction machinery, equipment and various raw materials, and conduct material testing preparation before construction. Check the prestressing equipment before entering the site.

Before construction, according to the beam span plane, use a total station to measure the outline position of the support foundation treatment range on the original ground. Perform support foundation treatment based on the released outline line.

Organize material entry. Rebars and prestressed materials must have factory certificates and be rechecked and approved by the laboratory by on-site sampling before they can be used. The storage site must be flat, dry, well ventilated and protected from rain, fully satisfying the processing and production needs of semi-finished steel. The site layout should be reasonable.

Complete various mix ratio designs in advance and report the selection of raw materials in a timely manner.

Measure and verify the horizontal and vertical position of the pier columns and bearings in advance.

The size of the bridge positioning control line (pile), leveling point and pier center positioning pile must be inspected and approved.

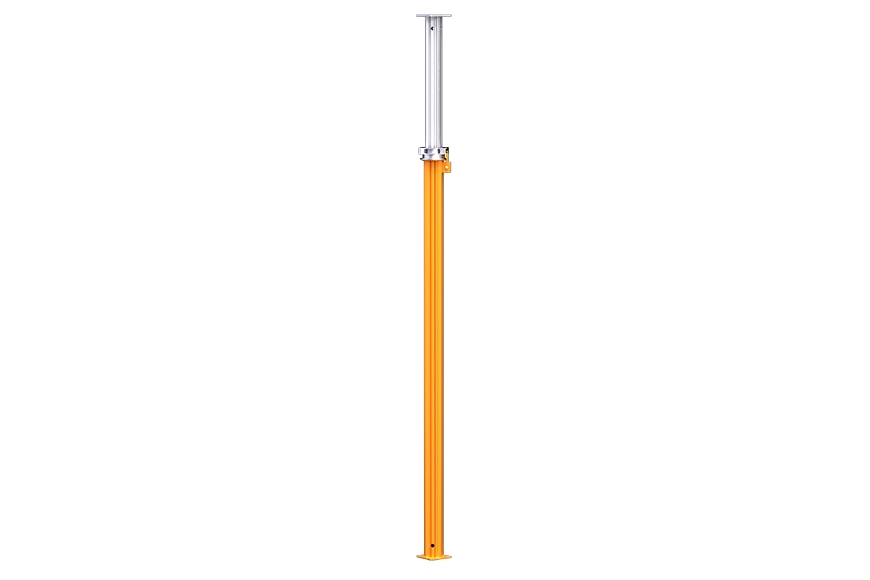

The materials such as steel pipes, bowl clasps, wooden stakes, I-beams, and safety facilities used in support erection construction must be prepared in advance and can only be used after passing inspection.

It must have sufficient strength, rigidity and stability, and can reliably withstand the various construction loads specified in the template construction standards, and ensure that the deformation does not exceed the allowable range.

It is easy to install and dismantle, and as much as possible, it is standardized and serialized. Templates with special requirements or complex operation procedures should develop operation rules at the same time.

Safety accessories are complete, and safety facilities and operation environments meet job requirements.

Self-designed bridge steel templates and their construction schemes, operation rules, etc. must be approved by the chief engineer of the unit.

With the professional R&D team and experienced technical team members from our formwork company, we will provide you with assistance on site when necessary, and you can rest assured that our solutions are always cost-effective. From the first contact to the completion of construction, we will always be there to support you. Welcome to inquire.