The raw materials (PP particles and fragments) are continuously sent to the PP hollow template extruder (integral equipment) through the hopper, and the materials are heated to 160°C~170°C (automatic temperature control electric heating) under automatic stirring to soften them. This process will produce a small amount of organic waste gas G1 (calculated as non-methane total hydrocarbons). The softened material is extruded and molded in the PP hollow template extruder. To complete the shape, it is conveyed to the cooling system through the conveyor belt for cooling (indirect cooling, cooling water circulation, Regularly discharging a certain amount of cooling drainage w1). After cutting, trimming, and finishing, a certain amount of unqualified products 51 and scrap S2 will be generated after the finished product is stored in the warehouse, which will be comprehensively utilized after being crushed by a crusher.

The plastic hollow building shuttering unit has a compact structure and superior performance. The screw and barrel are optimized and processed with high-performance alloy steel. The whole machine has the advantages of uniform plasticization, stable extrusion, high output, and long life.

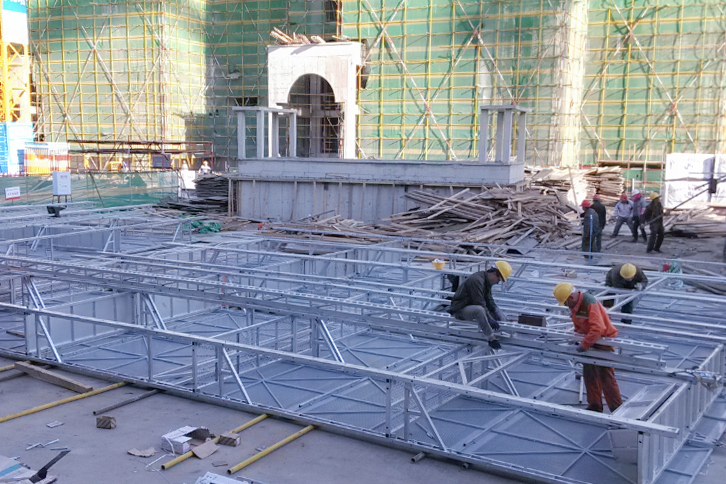

1. Characteristics of plastic hollow building shuttering

(1) The hollow plastic building shuttering has good workability. The construction method is the same as that of the wooden formwork.

(2) No moisture absorption, corrosion resistance, acid and alkali resistance, especially suitable for use in humid environments.

(3) High strength, impact resistance, abrasion resistance, long service life, and more than 50 cycles of use.

(4) The surface is smooth, bright, and clean, does not need to be brushed with a release agent, can be sawed, and can be nailed.

(5) The used waste boards and scraps can be recycled and reused, saving costs and reducing pollution.

(1) How to use: Like the wooden template, the vertical direction of the hollow plastic building shuttering and the direction of the wooden template form a cross.

(2) There is no need to apply a mold release agent before use.

(3) When the slab is cast in place, the keel spacing is 20~25cm, and the keel spacing of the slab wall is 15~20cm.

(4) The splicing seams between the hollow plastic building shuttering panels need to be sealed with tape.

(5) The nail length should not be too long, generally about 30~35mm.

(6) The nail strength should be moderate.

(7) When removing the mold, it is necessary to remove the template from the small piece at one end, remove the support while removing the template, prevent a large area from falling, and do not let the corners fall vertically against the ground.

(8) Plastic hollow building shuttering can be mixed with wood plywood, bamboo plywood, and other materials.