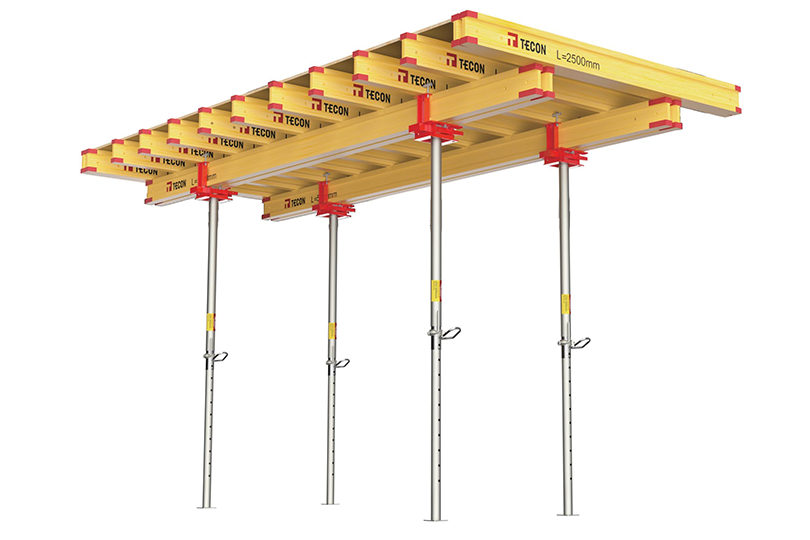

TECON Aludeck Slab Formwork is one of the most efficient and labour-saving decking system. It is consisted of 6061-T6 or 6082-T6 aluminium alloy frame panel, main beam, early stripping head and shoring prop. Assembly and slab forming can be implemented rapidly in residential and industrial construction projects with thicker slabs.

Light weight aluminium panels and TMP multi-purpose aluminium props make it a high efficent handset decking system

Early stripping heads reduce on site material requirements and result in quick deployment of panels

Easy to clean due to high-temperature powder coated frame

High load capacity TMP Aluminum prop means lower density slab props required, around 0.3 pieces per m² only

Multi-purpose aluminium props TMP can be extended to double or trible heights with MRK truss brace as reinforcement

Formwork panel is made from 6061-T6 or 6082-T6 profile lined with 9mm TECON-Form birch, the panel depth is 120mm

Panel length: 1500 / 750 mm; Panel width: 750 / 500 / 375 mm; Three lengths of main beams:1550 / 2300 / 3800 mm

The Aludeck panel weights around 15kg/sqm only

TMP multi-purpose aluminum prop, D class or E class heavy duty prop following EN1065 standard as the shoring

With 150cm main beam and 75cm width panel, the slab thickness can be casted up to 100cm

With 225cm main beam, the slab props for sale thickness can be casted up to 40cm

Multi-purpose aluminium props heights: 1200 / 2500 / 3500 / 4800 / 6250 mm, with maximum work load up to 90kN

Wide range of applications from residential & commercial buildings to civil engieering projects with thicker or higher slab.

You can send us your material list to request a quotation, or you can also simply send us the structural drawing and project information for complete formwork & scaffolding proposal via the below contacts.

Email: info@teconform.com

Phone: +86-512-65650586

Mobile: +86-13862020161.

By T/T or L/C.

For climbing formwork, self-climbing platform, plastic formwork, we have stock in our warehouse. The preparation of loading will be within 10 to 15 days.

For H20 timber beam, TECON-Form Shuttering, the lead time is from 15 to 25 days.

For other systems, the lead time is from 30 to 45 days.

For a more accurate lead time, don't hesitate to contact us for a specific product based on your quantity.