Special-shaped steel formwork is a commonly used mold in construction engineering, mainly used to create special-shaped buildings. These molds are usually customized, so the requirements for their own quality are relatively high. So what factors affect the quality of special-shaped steel formwork? We mainly think that these are the factors.

Adhesive quality

Mainly manifested in the performance of synthetic resin adhesive, the matching and adjustment of each component, and the adhesive process.

Substrate quality

The quality of the single board, especially the surface condition, has a great influence on the bonding strength of the special-shaped steel formwork. Therefore, the wood preparation and single board rotary cutting process should be given sufficient attention. The wood should be softened well, and the rotary cutting conditions should be controlled well. At the same time, the moisture content and flatness of the single board should be noted.

Aging time

The aging time should be suitable, and it should be able to change reasonably with the climate. The core board should be fully integrated to reduce the layering and separation of the core board. Pay attention to controlling the glue pressure conditions and reducing the pressure speed, especially when the moisture content in the billet is high.

Bonding force of the formwork

Before the glue is pressed, attention should be paid to mastering the two links of the amount of glue applied and the aging of the billet. If the amount of glue is too large, the cost is high, and the glue layer is too thick, the internal stress will increase, and it will be easy to penetrate the glue; if the amount of glue is too small, it will not be conducive to the infiltration of the glue solution, and the glue layer of the special-shaped formwork will be incomplete.

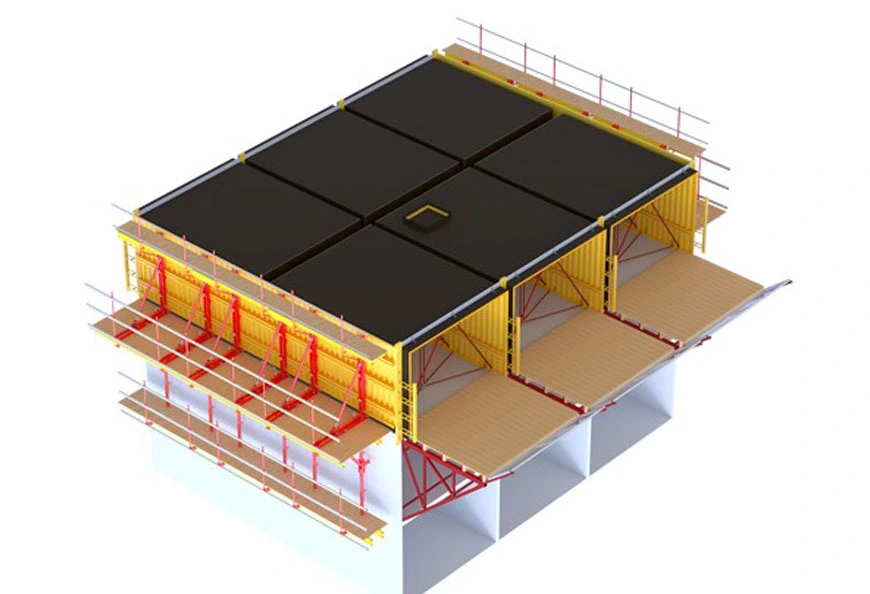

There are many types of steel formwork, including steel column formwork. In daily life, we see more of bridge steel formwork, cylindrical steel formwork, and special-shaped steel formwork. Of course, they each have their own uses and characteristics. So, how should we choose?

Earlier, we introduced the selection methods of bridge steel formwork and cylindrical steel formwork. Next, let me briefly talk about how to choose special-shaped steel formwork.

When choosing this type of steel formwork, it is recommended that you try to choose medium-sized combination formwork.

As you may not know, in general, the wall formwork can be made into large formwork by splicing medium-sized combination formwork as a whole or by using whole-layer multi-storey building formwork, or by using all-steel large formwork.

When you cannot find a suitable steel formwork, you can make various specifications of medium and small wood combination formwork by making full use of old multi-layer boards that have been cut multiple times and short residual wood squares.

At present, the number of curved walls is increasing, and the curvature is variable. Once it is processed into a fixed curved formwork, it will be very labor- and material-intensive. Therefore, we can also produce curved formworks with any radius by adjusting the adjuster, which is very effective.

In addition to the above-mentioned methods, we should also choose special-shaped steel formwork that conforms to our own production conditions as much as possible. Our company is one of the professional formwork manufacturers specializing in bridge formworks, with guaranteed product quality and affordable prices, and we welcome inquiries.