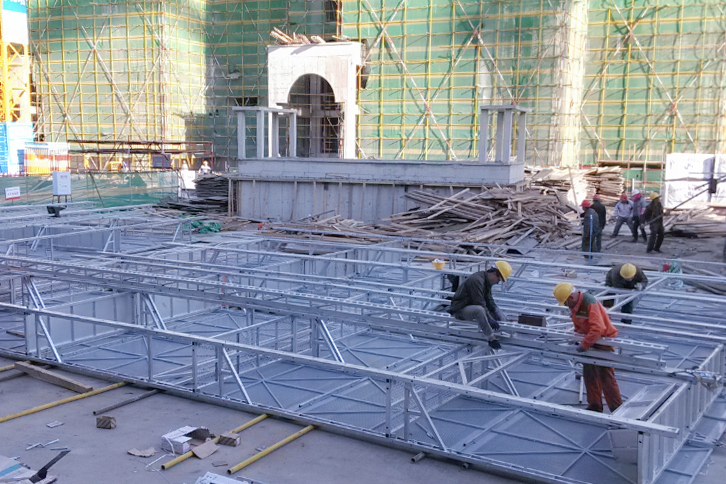

The building formwork is a temporary support structure, which is made according to the design requirements, so that the concrete structure and components are formed according to the specified position and geometric size, which can maintain their correct position, and bear the self-weight of the building formwork and the external load acting on it. The purpose of the formwork project is to ensure the quality and construction safety of the concrete project, speed up the construction progress and reduce the project cost.

However, in the process of construction, we often encounter the problem of the deformation of the building formwork structure. The deformed formwork will affect the quality of the project, so when the building formwork is deformed, many workers will immediately choose to replace it with a new formwork. Nothing can be 100% perfect. The same is true of building formwork. We need to find out the reasons for the deformation of the building formwork, and then find a way to solve the problem of the deformation of the building formwork.

(1) First of all, we must strengthen the foundation construction. If the foundation is not firm, when we place the building formwork, we cannot lay the building formwork flat. There is also the problem of waterproofing. If the waterproofing measures are poor, the foundation will sink. The foundation is the basis of all work. If the foundation sinks, the building formwork will be deformed.

(2) Wooden formwork or plywood is used for construction, or concrete is not poured in time after acceptance, and then the formwork is deformed due to long-term sun and rain.

(3) If the support spacing of the building formwork is too large, and the rigidity of the steel plate is poor, this will cause the deformation of the building formwork.

(4) When we are pouring wall or column concrete components, if the pouring speed is too fast, the height of one pouring will be too high, and the excessive vibration will also cause the deformation of the building formwork.

After we find the reason, we can prescribe the right medicine according to different situations, and then use some methods to prevent the deformation of the building formwork.

(1) The formwork assembly should be carried out in strict accordance with the size specified in the layout plan of the formwork. When the formwork is assembled on site, the joints between the adjacent formwork should be well controlled, and clips should be added at the joints of the two formwork to prevent the leakage of grout. After the assembly is completed, then use steel wire to bind the formwork and vertical steel pipe firmly to maintain the integrity of the formwork.

When the composite small steel formwork is assembled, the connecting parts should be placed according to the regulations, and the spacing and specifications of the purlins and the tension bolts should be set according to the design requirements.

(2) The distance between the supports at the bottom of the beam should be able to ensure there is no deformation under the action of concrete weight and construction load. If the support bottom is the soil foundation, it should be carefully compacted first, a drainage ditch should be set up, and long dunnage or profiled steel should be laid to ensure the support does not sink.

(3) When the wood/plywood building formwork is used for construction, concrete must be poured immediately after acceptance to prevent deformation of wood/plywood formwork due to its long-term exposure to the sun and rain. Or you can choose a good building formwork, such as hollow plastic alloy building formwork. After the building formwork is modified by PP, it has good acid and alkali resistance and weather resistance. It is light in weight and does not deform during use, which greatly improves the construction safety. The formwork is also the same as the steel formwork, with high impact strength and no moisture absorption, less seams, wear resistance and other characteristics, effectively alleviating the problem of formwork deformation.

(4) In the design of building formwork and support system, its own weight, construction load and concrete weight and lateral pressure generated during pouring and tamping should be fully considered to ensure that the building formwork and support have sufficient bearing capacity, rigidity and stability.

(5) If the beam and column building formwork adopts the clamping method, the spacing should be specified, and the building formwork should be clamped tightly, and its width should be slightly smaller than the section size.

(6) The upper part of the beam and wall building formwork must have a temporary support head to ensure the width of the beam and wall opening when the concrete is poured.

(7) When we are pouring and pounding concrete, it is necessary to uniformly and symmetrically cut the material and to strictly control the pouring height. Especially on both sides of the building formwork of the door and window openings, we should ensure that the concrete is vibrated and compacted so as to prevent the deformation of the building formwork caused by excessive vibration.

(8) For cast-in-place reinforced concrete beams and slabs with a span of not less than 4m, the building formwork should be arched according to the design requirements. When there is no specific design requirement, the arching height should be 1/1000 to 3/1000 of the span.