The initial step in table formwork construction is to make thorough preparations. This includes checking whether all components of the table formwork are intact, such as platform boards, support systems (beams, brackets, supports, legs, etc.), and other accessories (like lifting and moving mechanisms).

It is also essential to prepare the necessary materials and tools for the construction, such as jacks, pads, wooden wedges, safety ropes, and hooks. These tools and materials need to be in place according to the construction plan in advance to avoid chaos during the operation.

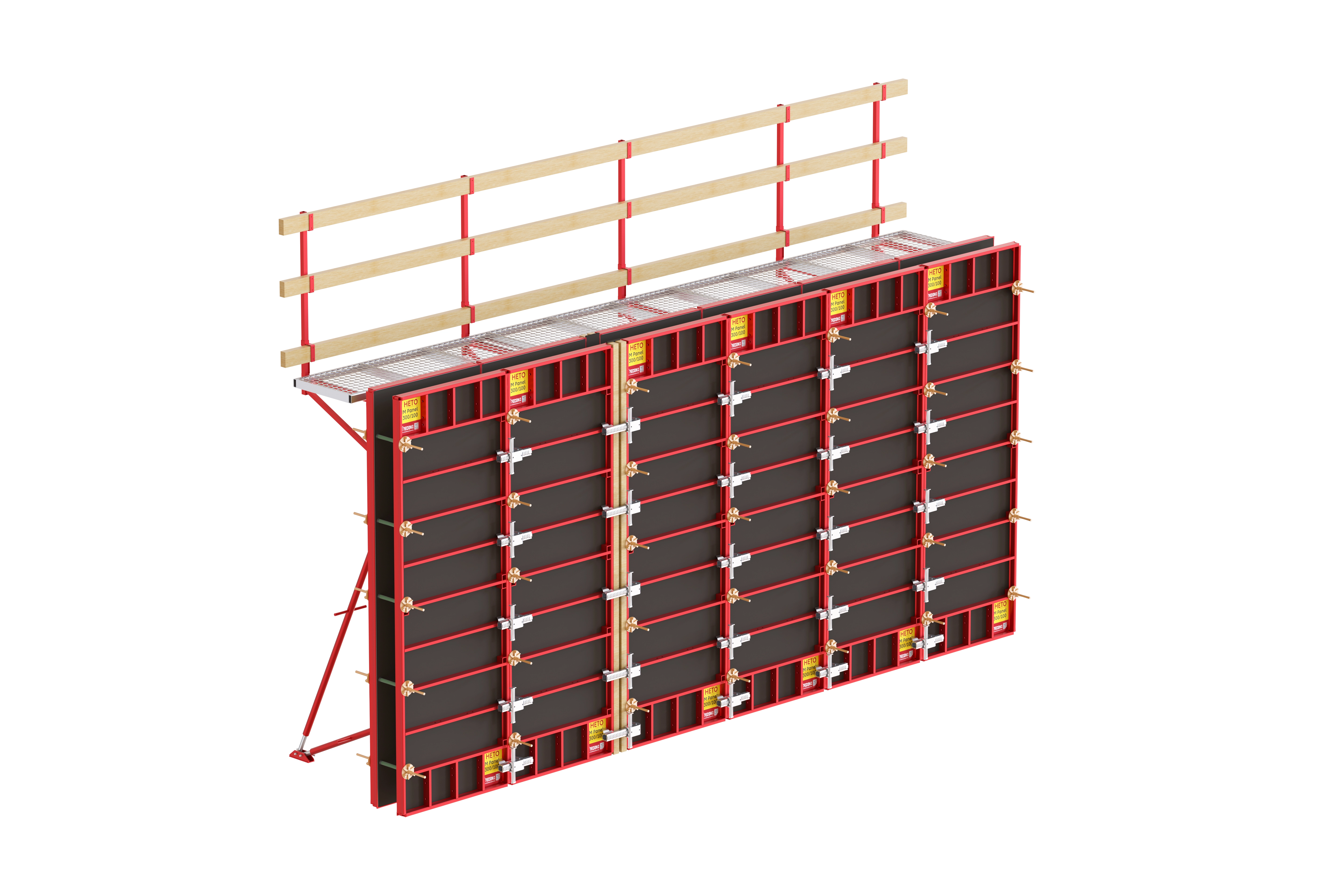

When assembling the table formwork, follow the design drawings to ensure each component is installed correctly, and all fasteners are tightened. After assembly, a pressure test should be performed to see if all components can withstand the load during construction. During testing, the lifting and moving mechanisms of the table formwork should also be checked to ensure they operate smoothly and do not jam or fail during construction.

Once the table formwork is positioned, use jacks to adjust the elevation, then place pads under the columns and wedge them with wooden wedges to ensure stability. After positioning, immediately set up guardrails and safety nets, with the height no less than 1.2 meters, to ensure the safety of the construction personnel. During reinforcement, check whether the gaps between the templates are sealed tightly to prevent leakage when pouring concrete.

Before pouring concrete, conduct a comprehensive inspection of the formwork to ensure the quality meets the standards. It's like washing your hands before eating; you need to ensure all preparations are done before starting the work. During pouring, strictly control the construction load, avoiding excessive or concentrated material to prevent deformation or collapse of the formwork. After pouring, carry out curing work to ensure the concrete reaches the designed strength.

When dismantling the table formwork, set up temporary supports to prevent large sections of the formwork from falling and causing safety incidents. After dismantling, use a crane to transport the table formwork to the next construction site, preparing for the next round of construction. During transportation, special attention must be paid to the use of safety ropes and hooks to ensure the table formwork does not fall or tilt.