Plastic formwork is an energy-saving and environmentally friendly product. The promotion and application of plastic formwork, "replacing wood with plastic", is a very important and effective measure to save resources and protect the environment. The development of plastic formwork is the development of circular economy, which is to participate in the construction of a conservation-minded society. The development prospects of the plastics industry are not only optimistic in China, but also in the world. This is not only because of the excellent characteristics of the product itself, but more importantly, it is determined by the significance of its resource recycling and its important contribution to environmental protection.

Although prefabricated buildings are also developing vigorously, there is still a long way to go to realize the industrialization of buildings. Even if prefabricated buildings have a slight impact on plastic formwork, a group of data from a plastic formwork company can illustrate the future of plastic formwork. prospect.

Practice has shown that plastic formwork saves about 30% of the cost of wood formwork, which does not take into account the labor and material costs involved in the release agent of wood formwork. Plastic building shuttering is cheaper than the recently emerging aluminum formwork, and it is easy to install and transport. With such superiority, plastic formwork will dominate the market in the future.

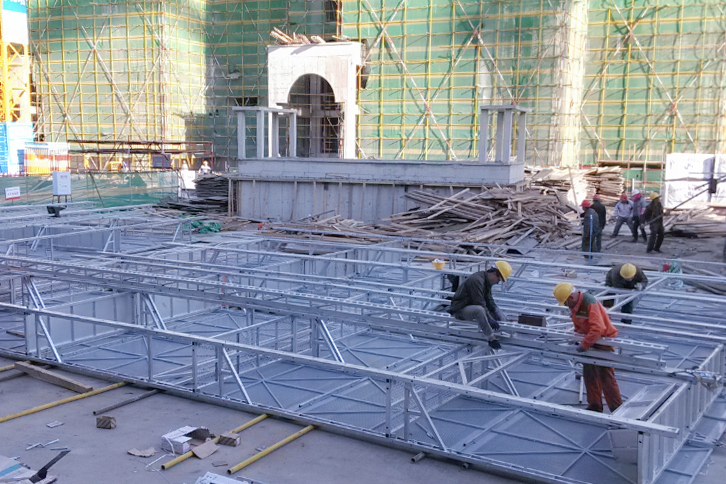

The weight is only one-seventh of the steel mold, and the weight of one square meter of plastic mold is about 8kg, which can be easily operated by female construction workers. The formwork is clean and easy to manage, and there are no problems such as residual nails and spikes on the construction site. Except for excavation, there is no need for large-scale machinery, and there is no problem of manual handling of heavy materials, which greatly reduces the hidden danger of construction safety.

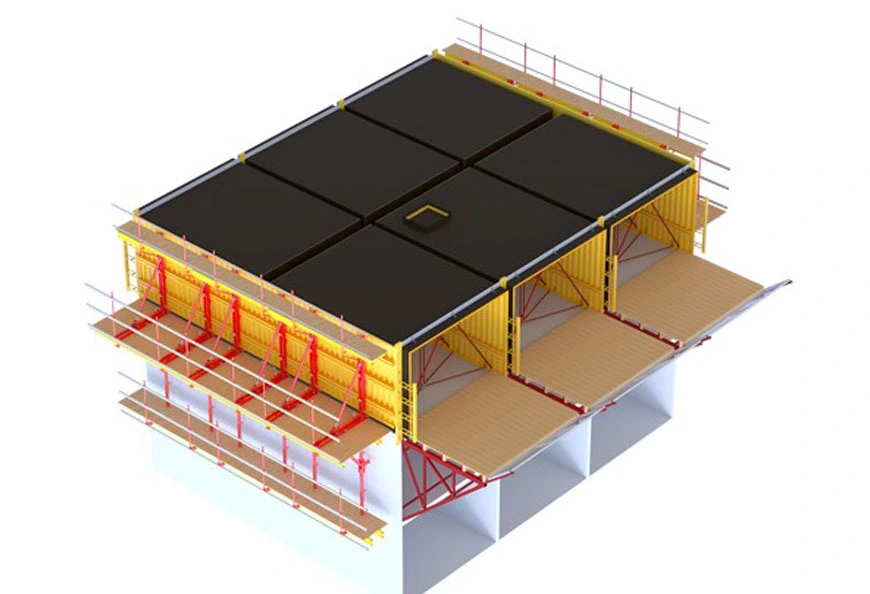

All of them use unified composite components, which are quick and convenient for construction, installation and disassembly. The construction efficiency of the same workload is more than 10 times higher than that of steel formwork and wood formwork.

Quick-easy mold has good wear resistance and corrosion resistance, is not easy to deform and is not easy to be damaged, and can be well applied to the requirements of different construction environments.

It is especially suitable for the construction schedule and construction site requirements of the expressway drainage ditch, which can not only ensure the quality and performance of the expressway drainage system, but also improve the service life of the expressway.

The formwork can be recycled more than 50 times, and the reuse rate is extremely high, and the construction cost is only one quarter of the construction cost of steel formwork/wooden formwork.

Therefore, no matter from its own characteristics or the influence of national policies, plastic building formwork has all-around advantages. In the future, the field of building formwork will definitely be the market of plastic formwork, which is the general trend!