During construction, if bridge formwork is used, it needs to be transported by car, and some problems must be paid attention to during transportation to avoid some accidents.

1. When hauling by car, the formwork that exceeds the height of the carriage rail must be fixed with ropes. It is forbidden to carry people in the carriage or on the formwork of the bridge at the same time.

2. During transportation, the driver must abide by the road traffic management regulations, and the speed should not be too fast.

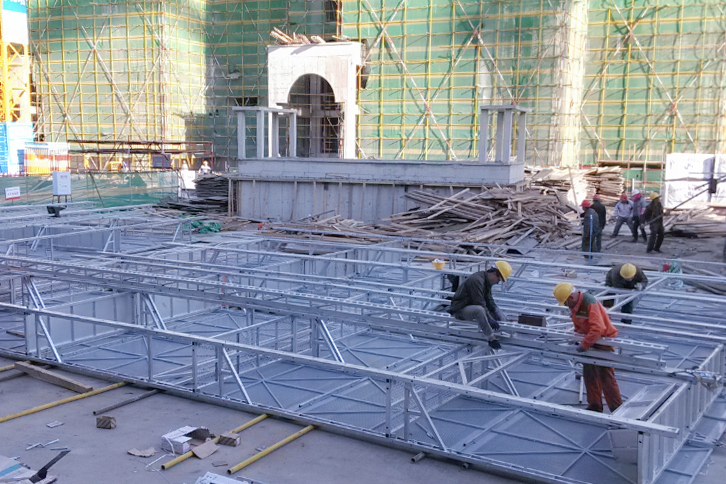

3. The bridge formwork transported to the construction site must be neatly stacked, with square wooden pads added to the lower part, and the stacking should not be too high to prevent dumping.

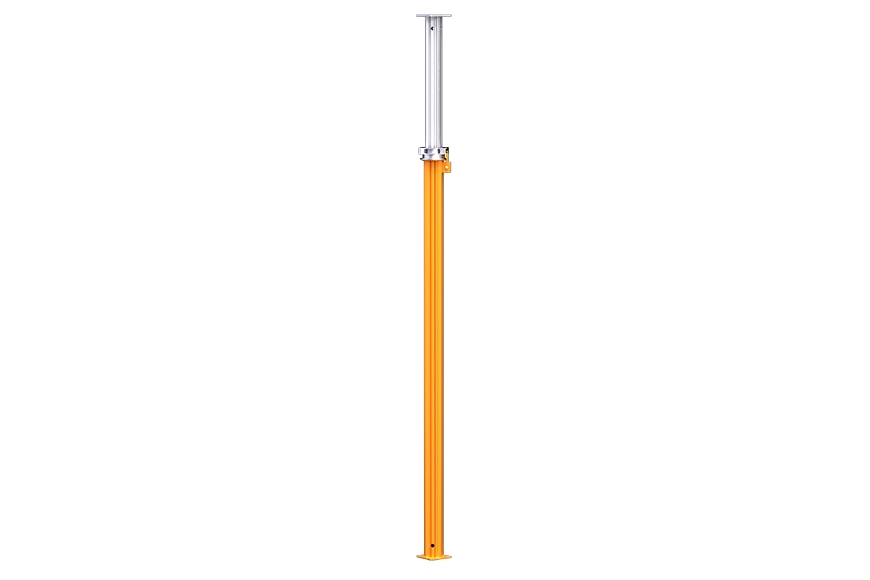

4. It is forbidden to stack the bridge steel formwork on the side. When stacking on the ringlock scaffolding system and construction platform, it must be stable to prevent it from falling off.

5. When the formwork is hoisted into the warehouse, it must be directed and hooked by the hoisting personnel. The formwork must be tied tightly, and the traction rope must be tied down. It is forbidden to lift a single rope, and it is forbidden to carry other objects in the formwork; various fasteners of the formwork must be It is packed in a tool bag, and a hanging basket must be used when it needs to be hoisted.

In the process of using formwork shuttering of bridge, there are many cases that the formwork has cracks, which is a more troublesome problem. To solve this problem, you need to pay more attention in the design stage of the template.

1. Prevention and control measures in the process of bridge formwork design:

To avoid the appearance of load cracks, the sudden change of the structure or the sudden change of the section should be avoided as much as possible. If structural sudden change is inevitable, detailed treatment should be done, such as rounding the corners, making gradual transitions at the sudden change, and strengthening the structural configuration to improve the crack resistance of concrete.

In order to prevent the cracks caused by the corrosion of the composite formwork, the bridge formwork design should strictly control the crack width according to the specification requirements, and use sufficient protective layer and anti-corrosion concrete.

2. Measures to prevent cracks in bridge formwork:

Before binding the steel bars, rust removal should be carried out to ensure the quality of the steel bars used. After the steel bars are centrally processed and formed in the processing plant, they are transported to the site for installation, and the spacing of the steel bars is strictly controlled during installation. The specification, model, quantity, spacing, geometric dimension, connection position and quality of the composite steel formwork should meet the requirements of the design drawings and construction specifications, and the raw materials and joint tests should be strictly carried out. There should be enough spacing between the reinforcement layers, and certain concrete pads should be set between the outer layer of the reinforcement and the formwork.