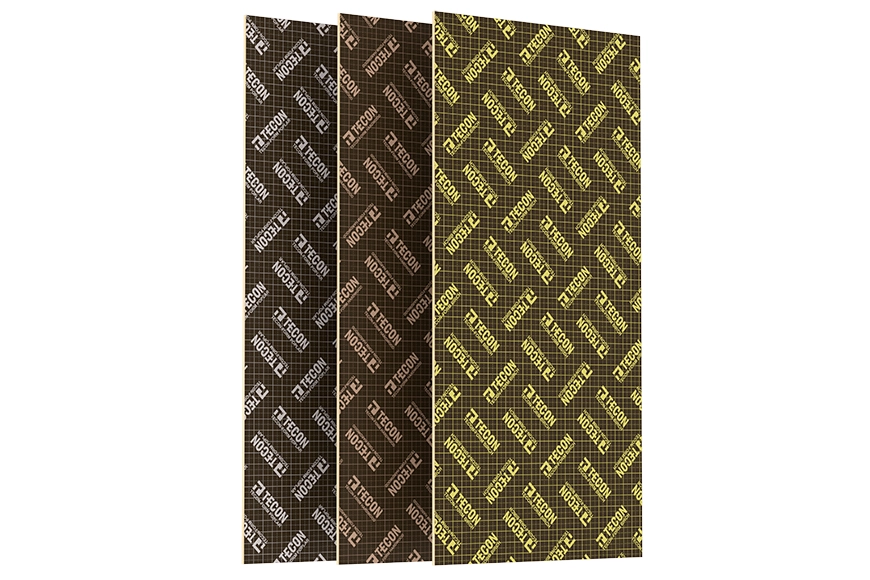

PVC concrete formwork, compared to traditional ordinary formwork, has significant advantages, especially in terms of construction efficiency and safety.

PVC concrete formwork uses a snap connection method, making both setting up and removing the formwork extremely simple and highly intuitive. The surface of the formwork is smooth and clean, allowing self-releasing from the mold without the need for additional release agents, saving the trouble of cleaning and maintenance. After use, the surface of the PVC concrete formwork can effectively isolate the cement, preventing adhesion, thus eliminating the step of cleaning the formwork. Compared to steel or bamboo-wood formworks, the construction efficiency of PVC concrete formwork is improved by up to 40%.

Under the same construction conditions, using PVC concrete formwork, for every 1,000 square meters of building area laid, about 40% of the time can be saved. This time saving is mainly reflected in the installation and adjustment process of the formwork, greatly improving construction efficiency.

PVC concrete formwork has a large difference in thermal expansion coefficient compared to concrete. After pouring, with changes in temperature, the PVC concrete formwork will automatically separate from the cured concrete, allowing easy disassembly without the need for knocking, significantly shortening the removal time of the formwork.

The density of PVC concrete formwork is only 0.7 grams per cubic centimeter, about 1/14 of steel, making the formwork extremely lightweight. Workers can easily transport each piece of formwork sized 900mm x 1800mm single-handedly, conveniently and quickly. Furthermore, this formwork does not deform or absorb water during use, ensuring construction safety, with a damage rate of less than one per thousand, greatly enhancing the work efficiency and safety level of the construction site.

Overall, PVC concrete formwork, with its light weight, easy disassembly, high efficiency, and environmental friendliness, has gradually become an indispensable ideal material in modern construction.