Steel formwork is a steel formwork used for concrete casting. Steel formwork is widely used in construction projects due to its multiple use and beautiful concrete casting.

Bridge steel formwork is a steel formwork specially used to build railway or highway bridges, and it is an indispensable material in the construction industry.

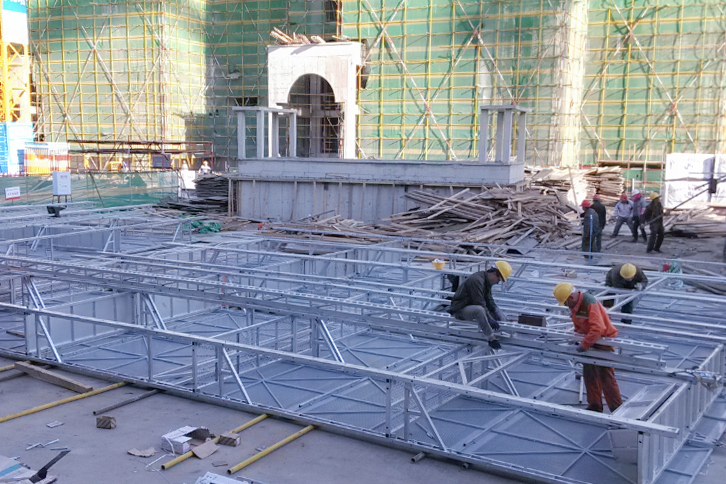

Construction steel formwork is often used in high-rise buildings. It has many different types, including Heto frame wall formwork, adjustable Heto frame system column formwork and single side wall framework.

Construction steel shuttering has the characteristics of high strength, good rigidity and durability. In addition, the structure is simple, the installation is quick, the repair is convenient, and the production efficiency is high. And it can be reused after simple recovery, saving costs.

1. Before the mold is dropped, the gangue debris between the building steel formwork and the well wall should be removed to prevent the mold from being stuck.

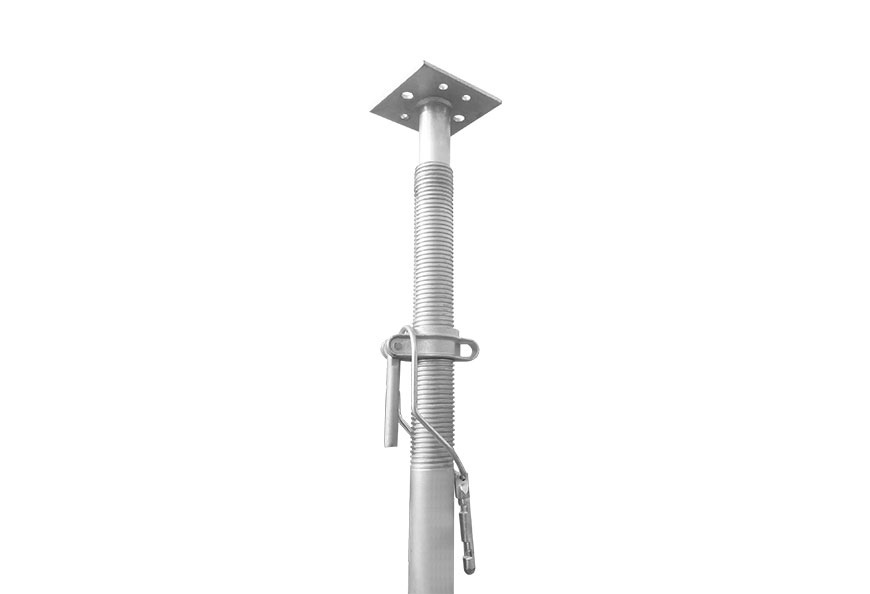

2. When the lead screw is not shortened or the construction steel formwork is stuck, it is forbidden to pull hard or hit the formwork with a bucket and a big grab.

3. In order to ensure the synchronization of the falling of the building steel formwork, a symbol can be made on the wire rope at the wellhead before the formwork is dropped, and it can be adjusted at any time according to the symbol and the stress condition.

4. When aligning, pay attention to the center line. If there is a slight swing, the center value must be taken. When leveling and aligning, ensure that the stubble is flat.

5. When the mold is dropped, the gangue on the building steel formwork should be removed first. No one is allowed to stand above and below the building steel formwork, and other personnel are not allowed to perform unrelated work.

6. When irrigating concrete, first fix the building steel formwork to the four beacon fires for irrigation, and then evenly increase the nearby areas in order, and a special person should be carefully tamped to prevent honeycomb, pockmarked surface, etc.

7. The suspension wire rope is five meters away from the building steel formwork, and it should be wrapped with a rubber hose to prevent it from collapsing. Check each piece before moving, once the damage exceeds the limit, deal with it according to the regulations.

Building steel formwork for concrete is a temporary support structure, which is the key to ensure the quality and construction safety of concrete projects, speed up construction progress and reduce project costs.

The building steel formwork must bear the horizontal load and vertical load during the construction of the concrete structure, which is the guarantee for the concrete structure to be poured and formed according to the design requirements.

Construction steel formwork is widely used in multi-storey and high-rise buildings with large span, large load and large space, such as shopping malls, office buildings, stations and other large and medium-sized public buildings.

As one of the leading experts in formwork and scaffolding engineering, our wide range of off-the-shelf and bespoke products ensures that we can provide a solution for your construction project, no matter the size or location. Welcome to consult.