Standardization

Engineering design must adhere to standards. For example, the design of the formwork for bridge steel should focus on the strength, rigidity, stability, shape, and size of the design, in accordance with national design standards.

Placement Drawing

If the bridge design were a battle, then the placement drawing would be the operational plan for the battle. The formwork manufacturers need the placement drawing to accurately mark the number and position of the steel formwork. Choosing larger panel areas can reduce the wear and tear of drilling holes in the steel formwork.

Longitudinal Splicing

Using longitudinal splicing can make the overall stiffness of the steel formwork more effective. It is worth noting that in the placement of bridge steel formwork, the structure and simplicity of the assembly and disassembly process should be ensured, and the placement process should not leak grout.

Ensure the correct shape, size, and position of the components.

Ensure that the steel formwork has sufficient strength, rigidity, and stability to withstand the weight and lateral pressure of newly poured concrete, as well as various construction loads.

Strive for simple construction, easy assembly and disassembly, not obstructing the reinforcement binding, and ensuring that the concrete does not leak during pouring.

The configured formwork should prioritize the selection of universal, large-panel formwork, reduce the number of types and pieces of formwork, and reduce the amount of wooden inserts. For the template set for pulling bolts, 55mmx100mm polished square wood can be used instead to reduce the drilling wear of the steel formwork at the bolt location.

The longitudinal splicing of the formwork should be arranged staggered to increase the overall stiffness of the formwork.

The formwork design should draw a placement drawing to indicate the position, specification, type, and quantity of the steel formwork. For the pre-assembled large-formwork, the boundary line should be marked. The positions of embedded parts and reserved holes should be indicated on the placement drawing and the fixing method should be specified.

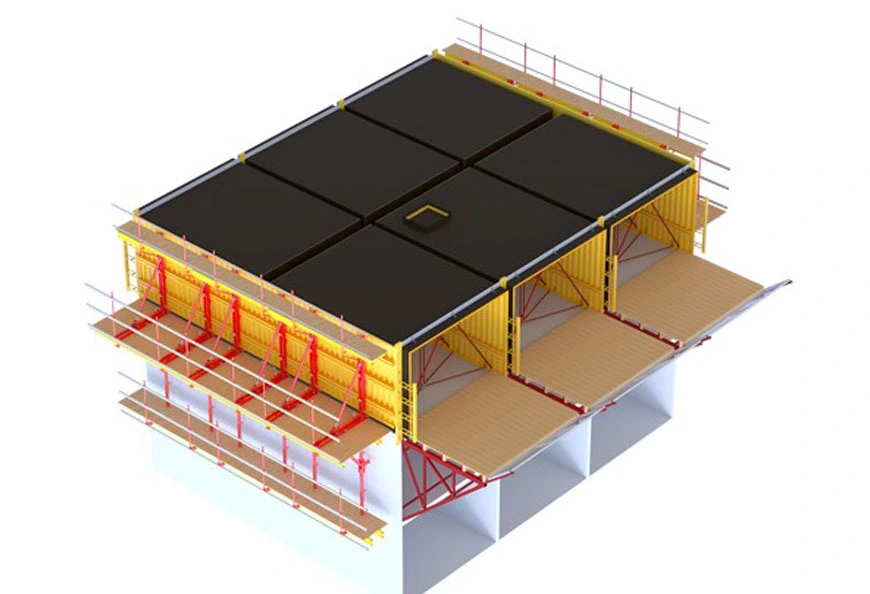

The support system of the formwork, including different types of formwork systems, should be arranged according to the load of the formwork and the stiffness of the components.

(1) When the end seams of the formwork are arranged horizontally, each panel of steel formwork should be supported by two steel ribs. When staggered, the spacing is not limited by the position of the end seam.

(2) Pre-assembled formwork that can be used multiple times in the same project should be connected with the support system to form a frame.

(3) The support system should be designed and calculated to ensure sufficient strength and stability. When the aspect ratio of the pillar or the interval between its nodes is greater than 110, it should be calculated according to the critical load and the safety factor can be taken as 3 to 3.5.

(4) For continuous or ladder-type pillars, horizontal braces and diagonal braces should be properly configured to ensure stability.