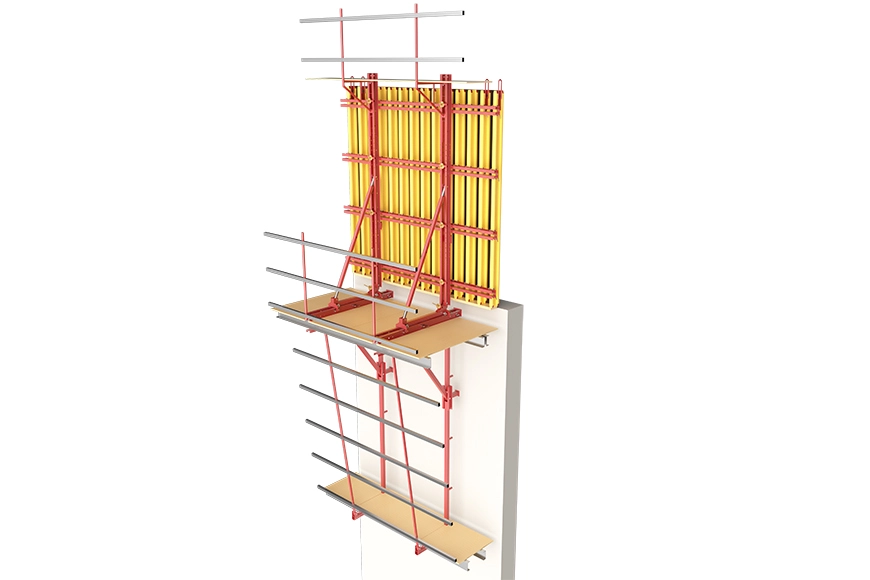

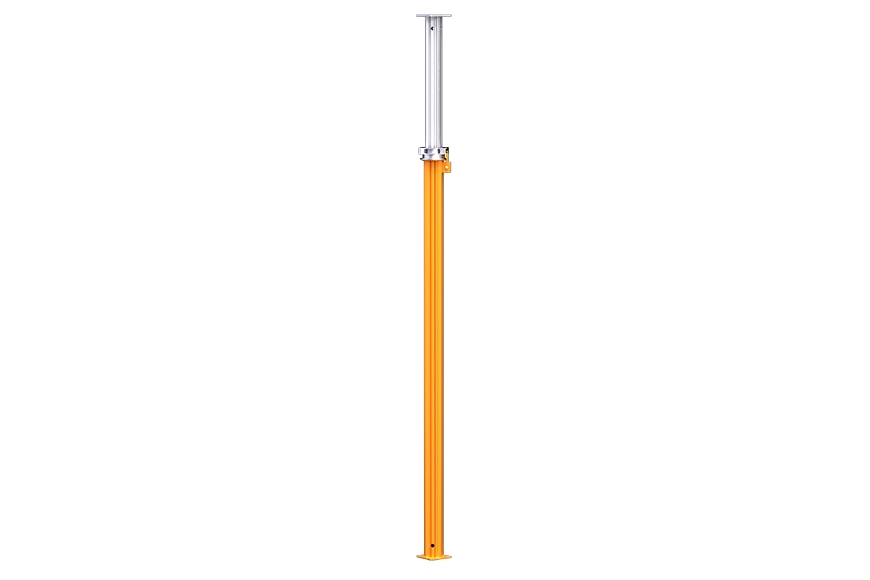

The bridge formwork is a model for newly poured concrete. The bridge formwork system consists of formwork, supports and fasteners. The mold for forming concrete structures or reinforced concrete structures consists of panels and support systems. The three major structural types of bridge formwork are introduced below.

Various cast-in-place reinforced concrete structural components have their own characteristics due to their different shapes, sizes and structures, and the structure and assembly methods of bridge formwork are also different.

According to the type of structure, it is divided into foundation wall formwork, pier round column formwork, bridge abutment (cap) formwork, beam formwork, crash wall formwork, tunnel formwork, etc.

(1) On-site assembly and disassembly formwork: The formwork is assembled on site according to the structural shape, size and space position required by the design at the construction site, and the formwork is removed when the concrete reaches the dismantling strength. On-site assembly and disassembly formwork multi-purpose stereotyped formwork and tool support.

(2) Fixed formwork: bridge formwork for making prefabricated components. According to the shape and size of the component, the formwork is made on site or in the prefabricated factory, the release agent is painted, and the concrete is poured. When the concrete reaches the specified formwork removal strength, the formwork is demolded, the formwork is cleaned, and the release agent is painted, and then the next batch of components is made.

It usually includes various prefabricated beam templates (hollow slab beams, box beams, T-beams, etc.) and other component templates.

(3) Mobile formwork: With the pouring of concrete, the bridge formwork can move in the vertical or horizontal direction, which is called a mobile formwork. Such as the sliding formwork and lifting formwork used for concrete pouring of chimneys, water towers and wall columns;

According to the different materials used, bridge formwork is divided into wood formwork, steel-wood formwork, plywood formwork, steel-bamboo formwork, steel formwork, plastic formwork, glass fiber reinforced plastic formwork and aluminum alloy formwork, etc.

As one of the leading experts in formwork and scaffolding engineering, our wide range of off-the-shelf and custom products ensures that we can provide a solution for your construction project, no matter the size or location.

With the expertise of our R&D team, our technical team members on-site to assist you when necessary, and knowing that our solutions are always cost-effective, you can rest assured that from first contact to construction completion, we are always there to support you. Welcome to consult.