Ⅰ. The distance between the vertical poles of the aluminum alloy formwork does not meet the requirements of the plan

Influence of hidden dangers: The distance between the poles does not meet the requirements. If the distance is too large, the bearing capacity of the support system will be significantly reduced, and the overall stability of the scaffold may be affected. In serious cases, it may lead to collapse and cause huge losses to the project.

Corrective measures: Make up the pole support according to the requirements of the plan.

Precaution:

Strengthen the process disclosure and construction acceptance, strictly follow the requirements of the plan, and make timely rectifications for the pole setting that does not meet the requirements. If the floor and beam bottom supports are equipped with early-demolition independent steel supports, the support spacing is less than 1.3 m x 1.3 m.

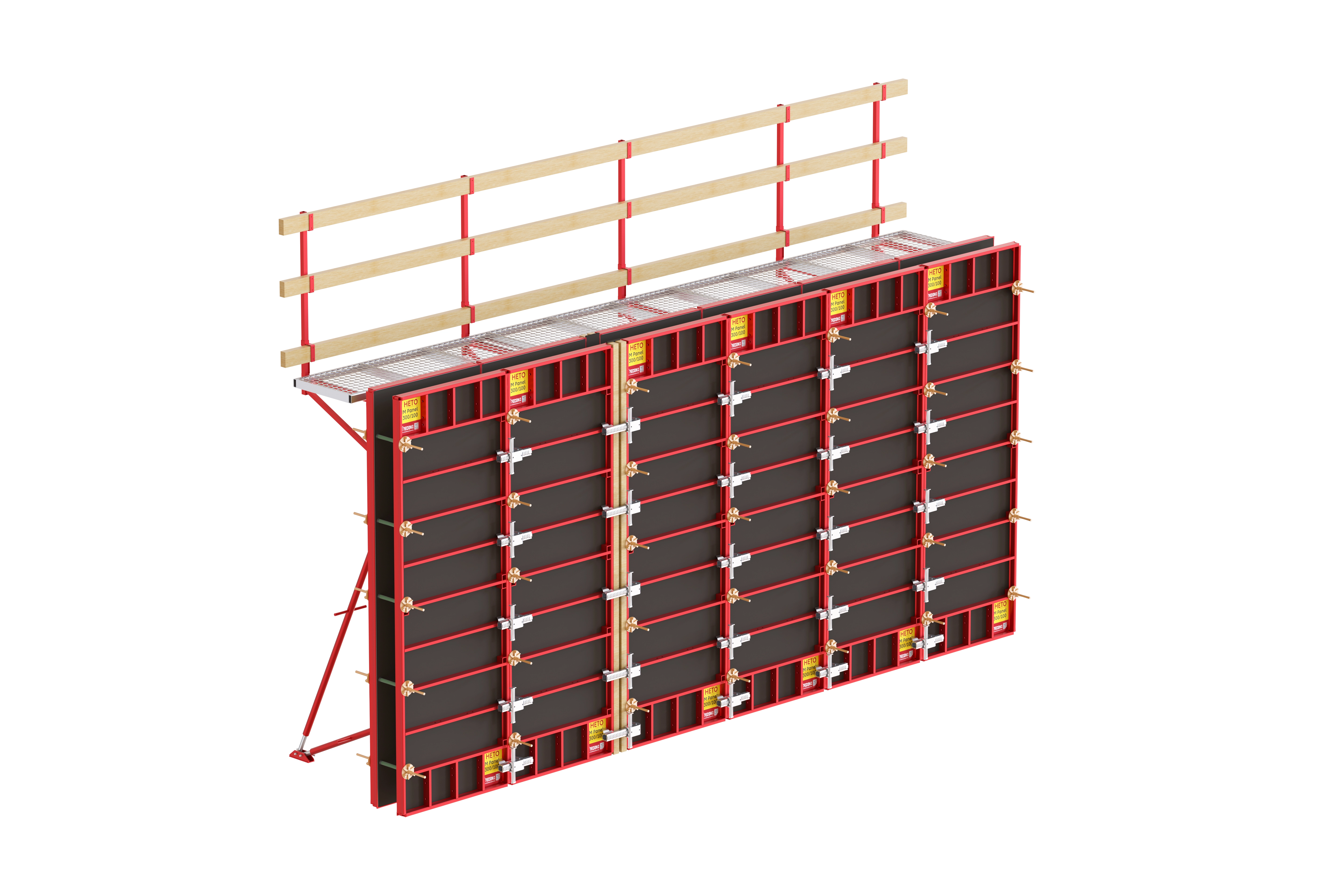

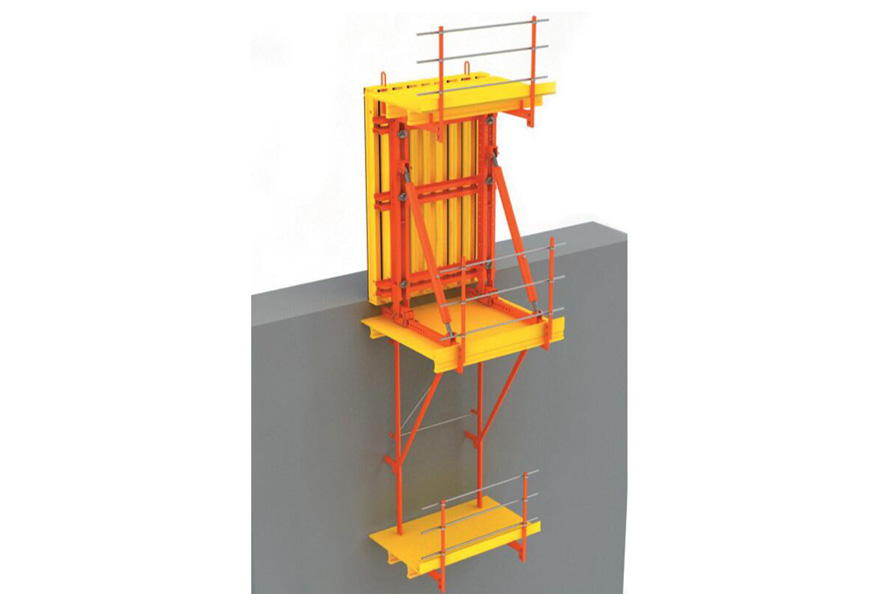

Ⅱ. The setting of the diagonal braces of the aluminum alloy formwork does not meet the requirements of the scheme

Influence of hidden dangers: The unsatisfactory setting of aluminium formwork diagonal braces directly affects the rigidity and stability of the formwork. It is easy to cause the formwork to become unstable and misaligned when the concrete structure is poured in the later stage, resulting in poor appearance of concrete forming quality and certain safety hazards.

Corrective measures: If the spacing between diagonal braces is too large and the installation does not meet the requirements, additional diagonal bracing should be installed.

Precaution:

Strictly follow the requirements of the plan, strengthen the process inspection and acceptance, and make timely rectification if the requirements are not met. Install diagonal supports on both sides of the column and wall. The body shall be provided with not less than two diagonal bracing, and the wall with a width of less than 1.2 meters and the short leg of the shear wall shall be provided with not less than one diagonal bracing. The floor slab shall be reserved for diagonal bracing to fix the embedded parts.

Ⅲ. The back corrugation and screw setting of the aluminum alloy formwork do not meet the requirements of the plan

Influence of hidden dangers: The unsatisfactory setting of the back corrugation and the screw will lead to the movement and bending deformation of the aluminium formwork wall panel, resulting in poor concrete forming quality.

Corrective measures: If the back corrugation and the spacing between the pull screws are too large, additional reinforcement should be added in time.

Precaution:

1. The construction shall be carried out in strict accordance with the requirements of the plan, and the process of acceptance shall be strengthened. The side formwork of the wall column shall be reinforced with back corrugation and opposite-pulling screws. The distance between the back corrugation of the bottom layer and the board surface shall not be greater than 300mm, the distance between the two back corrugations shall not be greater than 700mm, and the floor height shall be 2.8 Up to 3 meters of wall column, the inner wall column must be set with no less than 4 back ridges, and the outer wall column must be set with no less than 5 back ridges;

2. Back corrugation of beam side formwork When the beam height is less than 1 meter, no back corrugation is required. When the beam height is 1 to 1.2 meters, a back corrugation is set. When the beam height is greater than 1.2 meters, the back corrugated reinforcement is set according to the wall template.

Ⅳ. Aluminum alloy formwork back corrugation, missing screw or wrong use position

Impact of hidden dangers: The lack of aluminium formwork back corrugations and screws and unreasonable settings will cause the aluminium formwork wall panels to be not firmly fixed, resulting in explosive formwork for concrete pouring, affecting the appearance quality of the concrete structure, and there are certain safety hazards.

Corrective measures: For the middle where the spacing of the back corrugated bolts is too large, a pair of tension bolts must be added. The back corrugated with overlapping should be replaced and then reinforced, and the back corrugated lap should be avoided as much as possible.

Precaution:

In the construction of aluminum alloy formwork, a reasonable and feasible construction plan should be formulated, and the construction and reinforcement process should be checked strictly according to the plan, and the structural drawings and reinforcement drawings should be carefully reviewed. Block the position of the tie bolts. The horizontal spacing of the tie bolts is ≤800mm. The initial spacing is calculated from the starting edge of the inner wall. The spacing is set to 350mm, and the general spacing is set to 800mm. When the width of the wall is ≤400mm, the end A pair of tie bolts shall be arranged to be close to the wall plate under the beam, and a pair of tie bolts shall be arranged at the connection of the two back corrugations.

Ⅴ. The spacing between the pins and pins of the aluminum alloy formwork is too large, and the joints are not strict

Influence of hidden dangers: Too much spacing between the pins of the aluminium formwork will make the formwork not fixed firmly and the joints are not strict, which will lead to the occurrence of concrete leakage and misplacement, which will affect the appearance quality of the concrete surface and the subsequent construction.

Corrective measures: The holes in the corner board must be fully hit, and the missing ones need to be hit.

Precaution:

The spacing between the dowels of the wall column board conforms to the horizontal direction of 30 cm, that is, there are 2 pins in the horizontal direction of the standard board of 400 mm. In the vertical direction, one hole should be 30 cm long. The spacing between the dowels on the ceiling should be 25 cm, and all the dowel holes in the wall headboard should be filled and not vacant, so as to prevent the explosion point of the expansion mold.