The planning of aluminum formwork is based on construction drawings, and the deepening drawings required for the planning are prepared by compiling the construction drawings. Nowadays, the construction technology of aluminum formwork has become more mature, so many projects require not only structural beams, plates and columns, but also involve skimmed joints, waterproof joints, hanging beams under door openings, small standard door lintels, waterstop back slants, drip lines/grooves, fire door pressure grooves, sliding door pressure grooves and various pressure grooves.

The deepening drawings can be used to prepare the aluminum formwork system for modeling after the project confirmation. The modeling process is to install the corresponding standard formwork according to the structure indicated in the deepening drawing. After the installation is completed, the final planning effect is a production list, production drawing, packing list and assembly drawing.

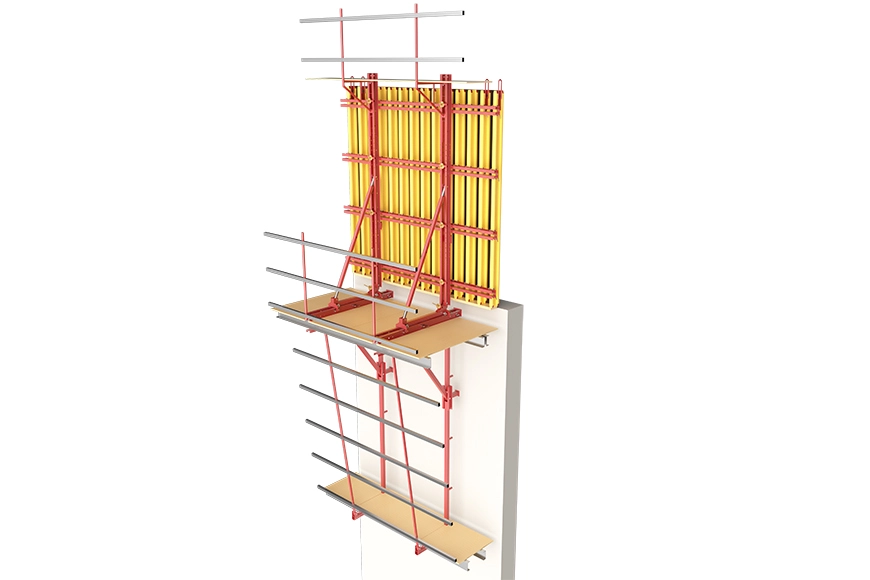

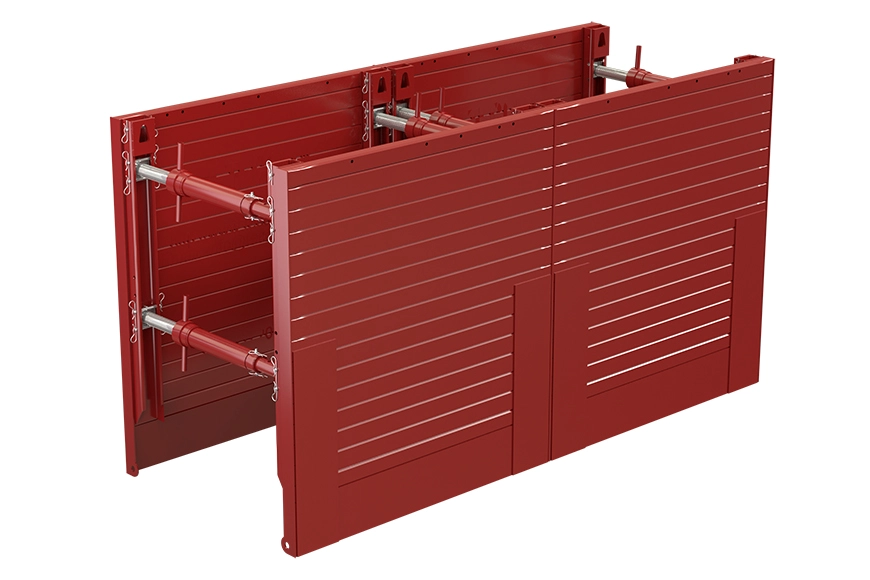

The reinforcement system of aluminum formwork mainly consists of two types of pull rods and pull pieces. The reinforcement of pull rods also relies on back ribs. The cement support bars in the center of the formwork ensure the wall thickness, and the glue cups and pipes on the rods also play a role. However, this reinforcement method requires high requirements for the planning of back ribs and the induction of construction teams. The reinforcement of pull pieces is to open pull piece slots between formworks and reinforce them by fixing them with nails. Back ribs only ensure the smoothness of the concrete forming.

There are mainly two methods for modeling, namely planar and 3D. In the early stage, planar modeling is mainly used, that is, standard and elevation are marked according to the deepening drawings. For example, floor slabs with only planar standards are relatively simple, while staircases and bay windows with standards and positions in the height direction require a higher level of planning skills and proficiency, as well as good spatial imagination.

The other formworks are reflected on the drawings as two-dimensional wireframes with standard shapes and equipment standards unable to be fully expressed. 3D modeling is relatively intuitive and simple. First, the deepening drawings are translated into a 3D model, and then the installation is based on the 3D concrete model. It can also be understood as a computer simulation process of restoring the assembly process on site. The 3D modeling model and the aluminum formwork that are modeled are all three-dimensional solids, with standard shapes and equipment standards (including pinholes, pull bolt holes, pull piece slots and various pressure grooves).

The early aluminum formworks all need to be trial assembled. The trial assembly process is a process of inspecting planning and production, and even some pull rod holes and pressure groove equipment are completed in the trial assembly process.

As the aluminum formwork becomes more and more mature, the trial assembly process will be eliminated sooner or later. To eliminate trial assembly, there must be a reasonable packing plan on the basis of ensuring the accuracy of planning. An unreasonable packing plan will waste a lot of time searching for materials on site.

The traditional packing method is to pack each household separately, plus one for the public area. This packing method will result in more than two thousand pieces of formworks in each package, which will naturally make material searching very labor-intensive.

As one of the leading experts in the field of formwork and scaffolding engineering, our extensive range of ready-made and custom products ensure that we can provide solutions to your construction projects, no matter how big or small or where they are located. Feel free to inquire.