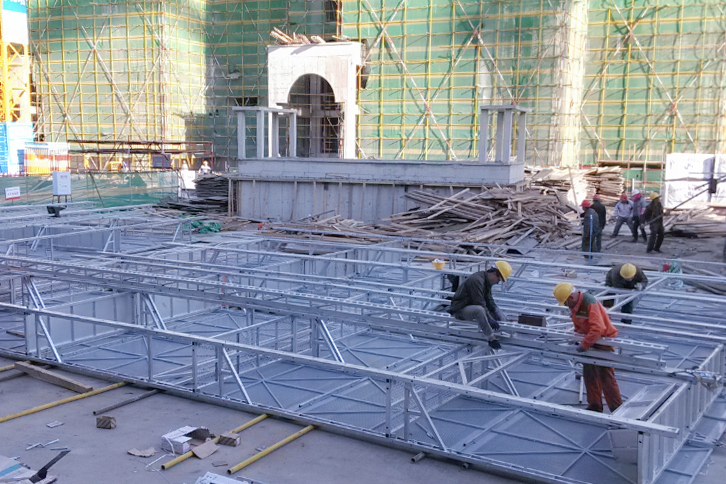

When assembling the bridge formwork, especially when shaping the bridge steel formwork, we need to pay attention to the following issues:

(1) All components of the formwork system are complete and firmly connected. The assembled formwork should be placed neatly according to its structural characteristics to ensure stability.

(2) Professional technicians must be arranged for technical guidance on the assembly site.

(3) Before assembling the formwork, check the components of the formwork system and inspect the appearance. Components with serious defects, bumps, deformation, etc. shall not be used.

(4) Steel bridge formwork is used for concrete pouring and molding. Metal formwork is widely used in construction projects due to its multiple uses and the beautiful appearance of concrete pouring. During the installation and use of bridge steel formwork, we must assemble in accordance with regulations to ensure effective work.

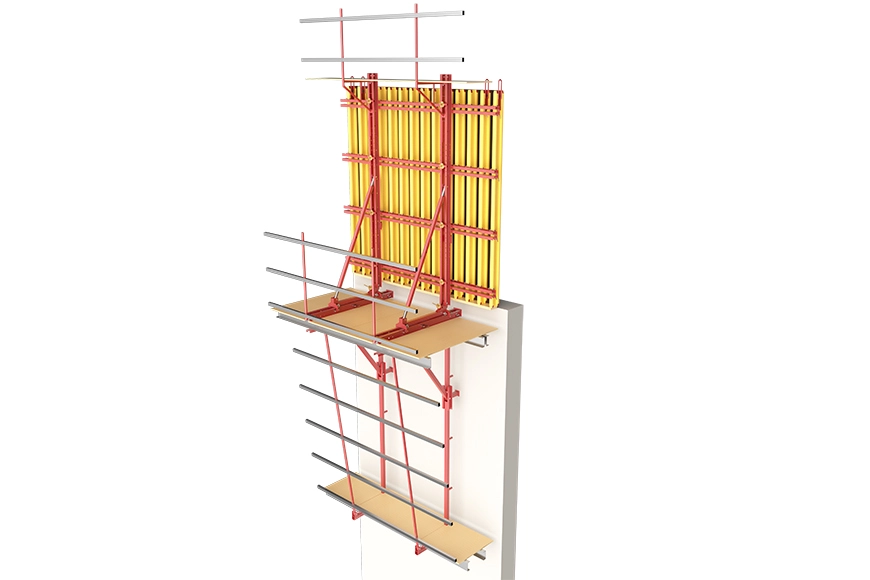

When disassembling the bridge formwork, we should pay attention to the following items:

(1) The internal mold with reserved holes (that is, the drawing pipe) should be removed when the concrete strength can ensure that the surface does not collapse or crack. The pull-out time should be determined through experiments, and the compressive strength of concrete should reach 0.8MPa.

(2) When the box girder is removed from the outer mold and the inner end, it must wait for the strength of the beam body to reach 60% of the design strength, that is, 30Mpa, before the mold removal operation can be carried out. In addition, the temperature difference between the surface concrete and the environment is not more than 15°C.

(3) Regarding the time for demolding of concrete, in addition to the strength of concrete when demolding, the temperature of concrete should also be considered. The temperature (caused by the heat of hydration of the cement) should not be too high, so as to prevent the concrete from falling too fast and cracking when it contacts the air, and it is not allowed to pour cold water for curing at this time. Before the temperature inside the concrete starts to cool down and when the temperature inside the concrete is high, the mold shall not be removed.

(4) The dismantling of the form shall be carried out in the reverse direction of the erecting form, and shall not damage the concrete so as to reduce the damage of the formwork. After the formwork is separated from the concrete, the formwork can be disassembled and lifted.

(5) The demolition of the bridge formwork should be carried out in the order of design, and it is strictly forbidden to throw away the formwork during demolition.

(6) After the formwork is removed, it should be repaired and sorted, and stored properly.