The requirements for the substrate treatment before the construction of the bridge template paint are as follows: no rust, no oil, clean, dry, with a certain roughness.

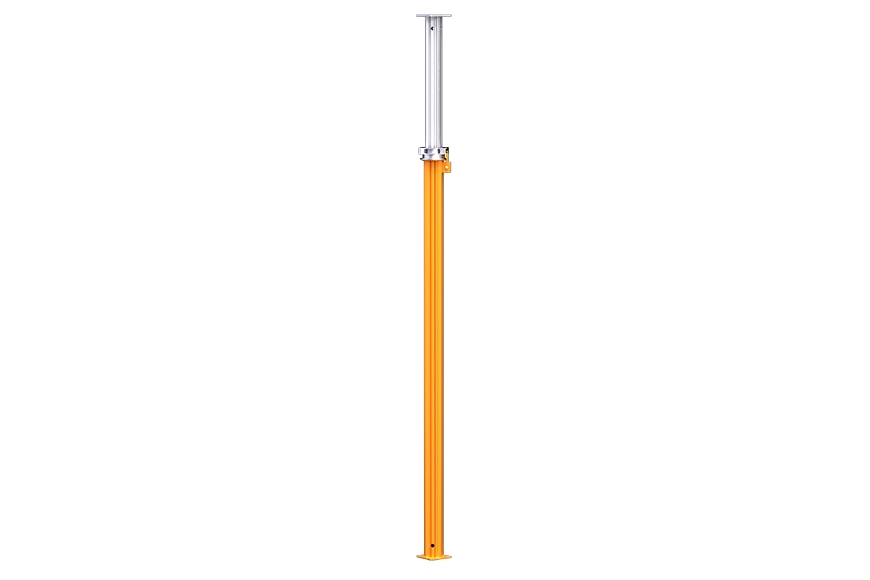

It is necessary to remove the floating rust, welding slag and other paints on the surface of the steel column formwork. When removing the rust on the flat formwork, it is generally necessary to use an angle grinder and a steel ball to remove the rust and remove the floating rust. In principle, it only needs to be processed once. If the corrosion is serious, the number of treatments can be appropriately increased, but be careful not to make the surface too smooth, which will affect the turnover times of the bridge formwork.

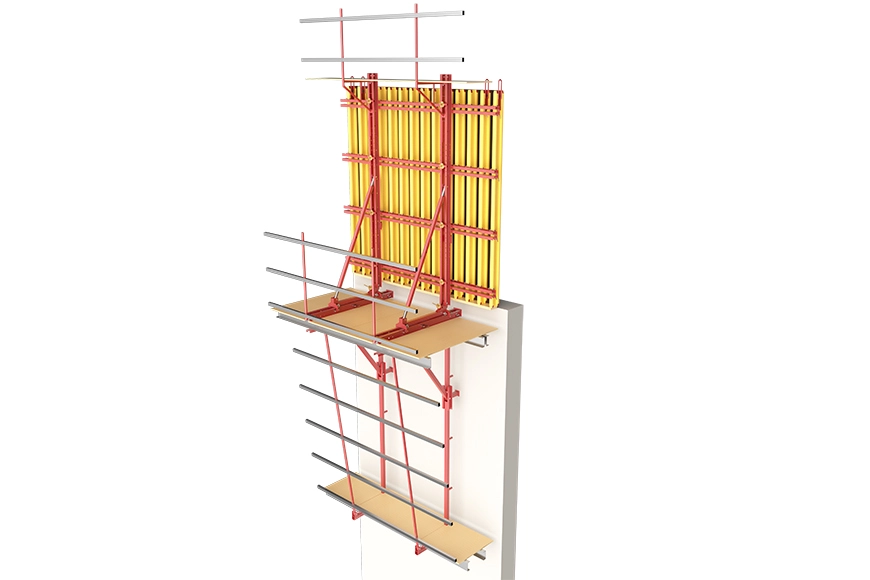

It is necessary to remove oil, salad oil or other oil stains on the surface of the steel formwork. The special-shaped formwork can be removed by using our matching product degreaser or detergent with strong detergency. The cleaning tools use hard floor brushes, divided into small floor brushes and horizontal floor brushes.

Before painting the stencil paint, it is necessary to keep the stencil clean. Some floating dust on the surface can be wiped off with a dry sponge, and then wipe the surface of the stencil with cotton cloth dipped in Tianna water (banana water) or turpentine water, and dry it with a dry cloth. Workers need to wear foot covers when painting, so as not to stain the template, and the wide template will affect the effect.

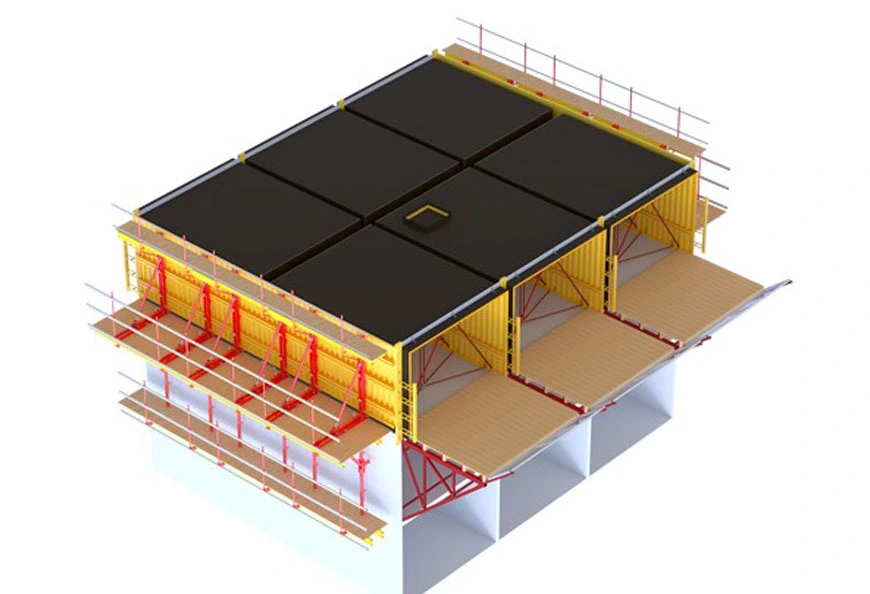

The bridge swivel construction process is suitable for the construction of single-hole or porous reinforced concrete bridges with a span. It is suitable for construction-restricted sites such as crossing deep valleys, deep waters and rapids, highway and railway interchanges, scenic spots, and nature reserves.

Bridge swivel construction relies on the rotation of the structure itself, without hoisting equipment, and can save support wood or steel. The construction process of the formwork bridge construction and the construction machinery used are simple. When rotating, only two reels and several sets of pulleys are needed to make the upper structure rotate in a short time, which is simple and easy to operate, easy to operate, and easy to popularize.

With the expertise of our R&D team, our technical team members are there to assist you when necessary, and knowing that our solutions are always cost-effective, you can be confident that from the first contact to the completion of construction, we will always be there to support you.

We encourage everyone on the team to give their best for themselves, colleagues and each client. As a company, we provide the best for our employees, colleagues, partners and customers. If necessary, welcome to consult.