Bridge formwork swivel construction refers to a construction method in which the bridge structure is formed (pouring or splicing) at a non-design axis position and then placed in place by swivel. It can transform operations over obstacles into operations onshore or near the ground.

According to the rotation direction of the bridge structure, it can be divided into vertical rotation construction method, horizontal rotation construction method (referred to as vertical rotation method and horizontal rotation method) and the combination of horizontal rotation and vertical rotation, among which the horizontal rotation method is widely used.

Compared with traditional construction methods, bridge formwork swivel construction has the following advantages:

1. It has reasonable structure, clear force and good mechanical properties.

2. The construction requires less machinery and equipment, the process is simple, and the operation is safe.

3. The swivel method can better overcome the difficulty of erecting large-span structures on high mountains and canyons, deep waters or rivers that are often navigable, especially for the construction of urban overpasses and railway overpasses with heavy traffic, its advantages are more obvious.

4. The construction speed is fast, the cost is low, and the investment is saved. Under the same conditions, compared with the traditional suspension assembly method, the truss outreach method and the erection method, the arch bridge adopts the swivel method, and the economic and social benefits are very significant.

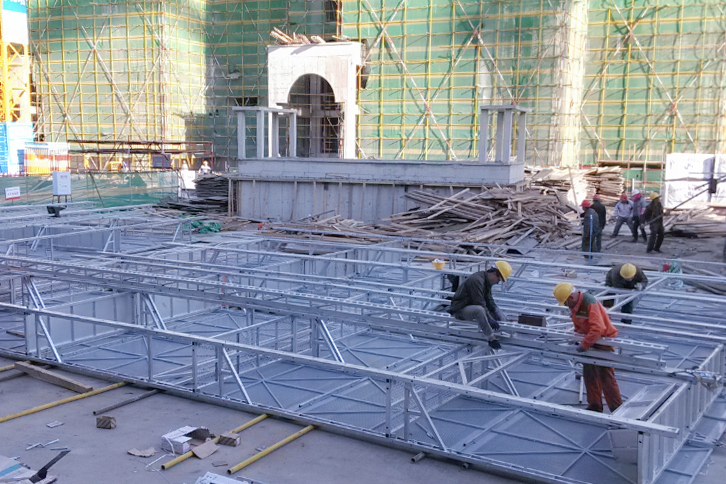

In many types of buildings, bridges are a very important part, so bridge formwork is also very important. It is mainly used in bridge projects, and the construction of the desired bridge is realized through steel formwork. Because of the safety requirements of bridge formwork, it is very important to choose bridge formwork. The following will introduce the selection criteria of bridge formwork.

1. The bridge steel formwork should ensure the correct shape, size and mutual position of the components.

2. The formwork must have sufficient strength, stiffness and stability to withstand the weight and lateral pressure of newly poured concrete, as well as various construction loads.

3. The bridge steel formwork strives to be simple in structure, easy to assemble and disassemble, does not hinder the binding of steel bars, and ensures that there is no leakage of slurry during concrete pouring.

4. For the prepared bridge formwork, general-purpose and large-block formwork should be selected first, so that the types and number of blocks are small, and the amount of wood formwork (like plastic film faced plywood) inlays is small. Set up the template for pulling the bolt, in order to reduce the drilling loss of the steel template, you can use 55mmx100mm planed square wood instead of the bolt.

5. The formwork should be staggered in the lengthwise splicing to increase the overall rigidity of the formwork.

6. The support system of the formwork should be arranged according to the load of the formwork and the stiffness of the components.

7. The layout of the bridge formwork should be drawn with a layout diagram, and the location, specification, model and quantity of the steel formwork should be marked. The pre-assembled large formwork should be demarcated. The position of the embedded body and the reserved hole shall be marked on the layout drawing, and the fixing method shall be indicated.