Construction formworks are an essential auxiliary material in building construction. Their role is to provide a relatively flat surface and defined geometric shape for concrete during pouring. Therefore, the specification and size of construction formworks are very important for ensuring construction quality and improving construction efficiency. This article will provide detailed information regarding the specifications and sizes of construction formworks.

Wooden formworks: Wooden formworks are the most widely used type of construction formworks. Their main material is wood, commonly used woods include pine, eucalyptus, and willow.

Steel formworks: Steel formworks are a high-strength, durable type of construction formwork. Their main material is steel, commonly used steel includes Q235, Q345, among others.

Plastic formworks: The reusable plastic formwork is a new type of construction formwork. Their main material is polypropylene, which is lightweight, durable, and easy to disassemble.

Flat Panel formworks: Flat panel formworks are planar formworks mainly used for pouring walls, floors, roofs, and other horizontal surfaces.

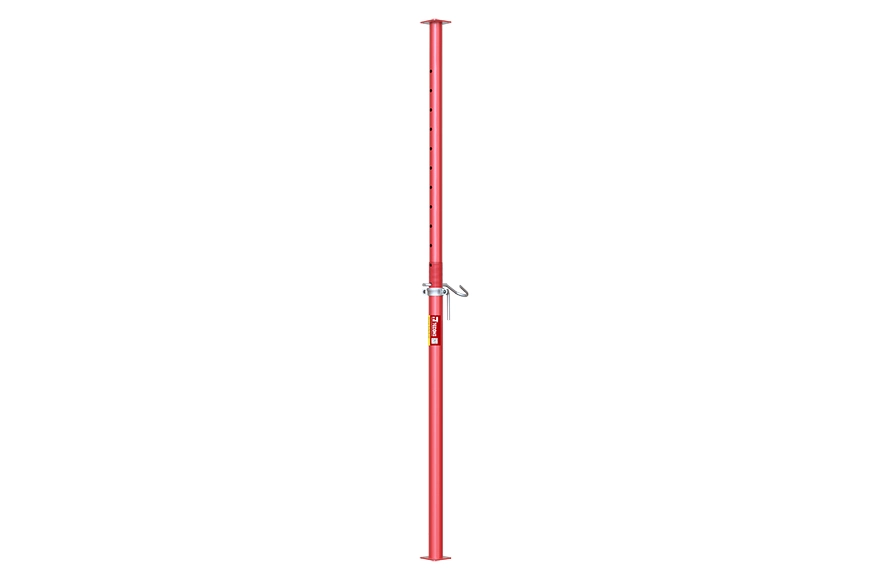

Column formworks: The round column formwork is a three-dimensional formwork mainly used for pouring columns and beam-column joints.

Framework formworks: Framework formworks are combination formworks composed of horizontal and vertical frames, mainly used for pouring large horizontal surfaces.

The specifications and sizes of construction formworks should be selected according to specific construction needs, generally considering the following factors:

Generally, the higher the concrete pouring height, the larger the formwork specifications and sizes should be.

The concrete pouring area is also an important factor in selecting formwork specifications and sizes. Typically, large concrete pouring areas require larger formworks.

The construction period is also an important factor in choosing formwork specifications and sizes. Generally, projects with shorter construction periods can select larger formworks to improve construction efficiency.

Site conditions are also an important factor in choosing formwork specifications and sizes. For example, on sites that are narrow or with complex terrains, formworks that are smaller and easier to transport must be selected.