The various materials used to produce composite steel formwork include main materials such as steel plates and steel sections, and auxiliary materials such as welding electrodes and paints. The raw materials for all types of materials should comply with the relevant national standards. The steel for the main material is Q235, and the medium quality grade can be selected from A, B, or C. The deoxidation method uses steel Z. The raw materials of the general steel plate should be reviewed or inspected according to the relevant current national standards before the formwork is manufactured.

Currently, many production plants use steel raw materials for formwork that do not meet the requirements of the standards. Some manufacturers even use recycled steel to produce formwork, which cannot meet the construction requirements.

In addition, many steel formwork factories use steel plate with a thickness name of 2.50mm, but actually only use 2.20mm to 2.30mm. The rigidity and strength of the steel formwork cannot be guaranteed, which seriously affects the manufacturing quality and applicability of the steel formwork.

The raw material for scaffolding steel pipes in the original standard is Q235, because low-alloy steel pipes show better physical and mechanical properties than ordinary carbon steel pipes. Currently, many scaffolding companies have also chosen Q345 steel pipes.

Therefore, the revised standard should make corresponding compensations for the raw materials of steel formwork and steel pipes and process steel formwork with modified steel.

What are the advantages of composite steel formwork, including formwork boards for sale, compared to traditional wooden formwork and old-style steel formwork? Let us explain:

It has a wide range of applications and is suitable for different engineering scales, structural forms, and construction processes, such as on-site assembly, overall lifting, sliding mold, climbing mold, etc.;

It has a long service life, high component strength, good durability, and can be quickly turned around. If it is repaired in time and protected properly, it can become a long-term use item;

The manufacturing accuracy of the panels is high, the joints are tight, the rigidity is large, and it is not easy to deform. The formed concrete structure is accurate in size, compact and bright;

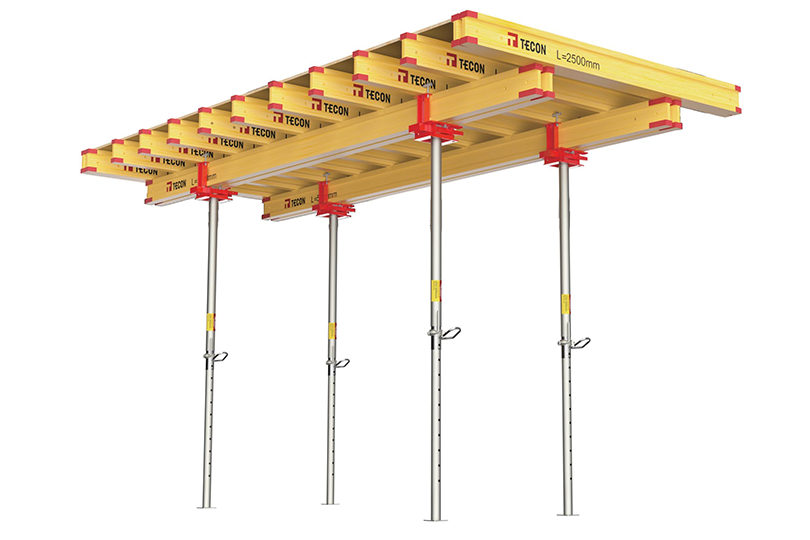

The composite rigidity is high, the panels are arranged in a staggered manner, the splicing panels have a plane overall rigidity. The panel is combined into a column-beam shell, which is itself a load-bearing member, and can further improve the overall rigidity, facilitate overall lifting, and simplify the support structure.

With our professional R&D team and experienced technical team members from our formwork company, we will provide you with help on-site when necessary, and our solutions always have cost-effectiveness. You can rest assured that we are always there to support you from the first contact to the completion of the construction. Welcome to consult.