1. Equipment involving major potential safety hazards must be approved by the security inspection department and the competent unit and issued an acceptance certificate and it cannot enter without the consent of the supervision safety engineer, including truck crane, crawler crane, tower crane, gantry crane, bridge erecting machine, beam transportation equipment, hanging blue, climbing formwork, rock drill, etc.

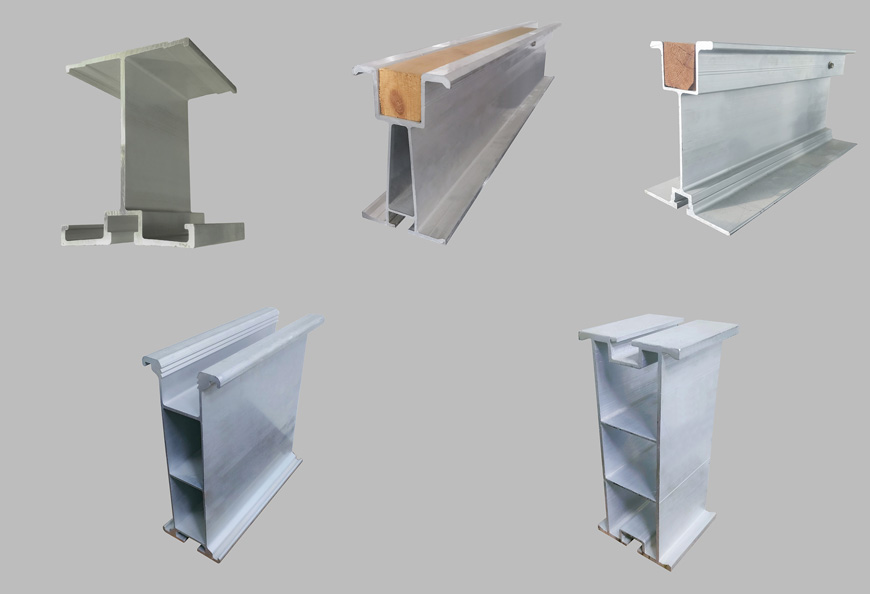

2. All bridge shuttering must be approved by the resident supervisor before entering the site: the processing unit is qualified and the assembly inspection is qualified. Any deformation, staggered joint and unqualified exposed surface shall be removed from the site.

3. Large surface steel formwork must be adopted to reduce joint. The height of each section of column pier and solid pier bridge formwork shall not be less than 4m, and the plane formwork of wall body shall not be less than 2 * 1.5m.

4. The design, manufacturer selection, trial assembly acceptance and first piece test of precast beam formwork system, hanging blue formwork and tunnel secondary lining trolley formwork must be reported to the director's office for approval before implementation.

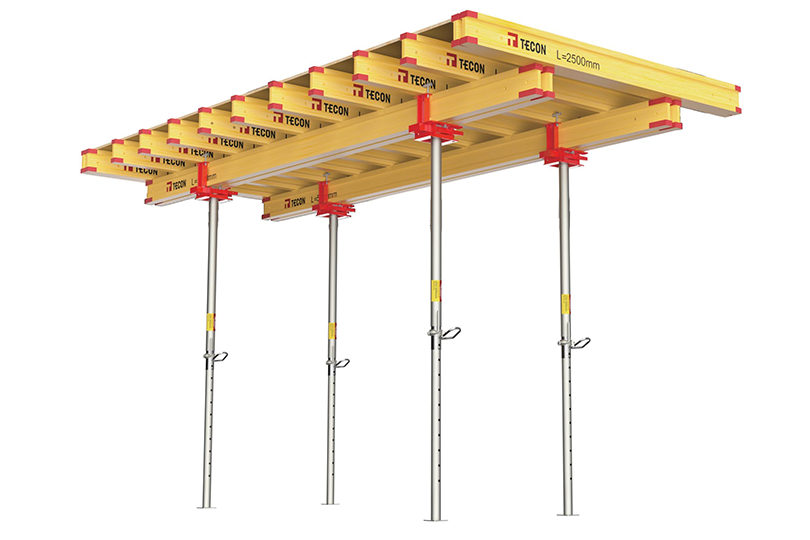

5. The formwork braces and supports of integral cast-in-situ structure bridge must be specially designed. The calculation results reviewed by the third-party qualified design unit shall be issued and submitted to the design unit of the project for confirmation before implementation.

6. The rigidity of the bridge shuttering must be ensured and will not deform within the service life. The through center pull rod shall be used as less as possible for the precast beam formwork, pier body and pier cap formwork.

1. Earnestly strengthen the supervision of construction quality and safety of bridges and other construction projects. The key points of inspection are: whether the qualifications of participating units and practitioners such as design, construction and supervision of the construction project meet the requirements; Whether the site construction, supervision and other management personnel are in place; Whether the quality safety, test detection and concealed acceptance of foundation and main structure works, as well as the acceptance of key processes related to structural safety such as concrete, reinforcement, prestress and bridge shuttering support meet the requirements of standards and specifications.

If major potential quality and safety hazards are found in the inspection, it shall be ordered to stop work for rectification. Those who violate relevant regulations shall be resolutely put on file for investigation and punishment.

2. Strengthen the special rectification of "collapse prevention, fall prevention and anti three violating rules". All localities should further strengthen the safety supervision of bridge formwork support systems with ultra-high, overweight, long-span and high risk, such as bridge shuttering. In strict accordance with laws, regulations and relevant provisions, urge the construction unit to prepare the construction scheme in strict accordance with the standards and specifications. Supervise and urge the supervision unit to review and inspect the construction scheme in strict accordance with the standards and specifications to ensure that the construction site is constructed in accordance with the construction scheme.

3. In the construction of bridge formwork, all construction units shall earnestly implement the safety production responsibility system, strengthen the daily management and inspection of quality and safety on the construction site, strengthen the safety education and training of front-line personnel, especially project managers, technical directors and full-time safety officers, and enhance the awareness of quality and safety responsibility.