With the development of urban modernization, there are more and more high-rise buildings, and people's requirements for green and safe construction and engineering quality are also improving. The traditional wooden formwork construction technology is no longer satisfactory in terms of safety, efficiency, and engineering quality.

The aluminum alloy formwork is a new generation of building formwork, which has gradually occupied the construction market with its advantages of environmental protection and high reuse rate. The aluminum formwork has been widely praised by the industry for its outstanding economic benefits and practicality.

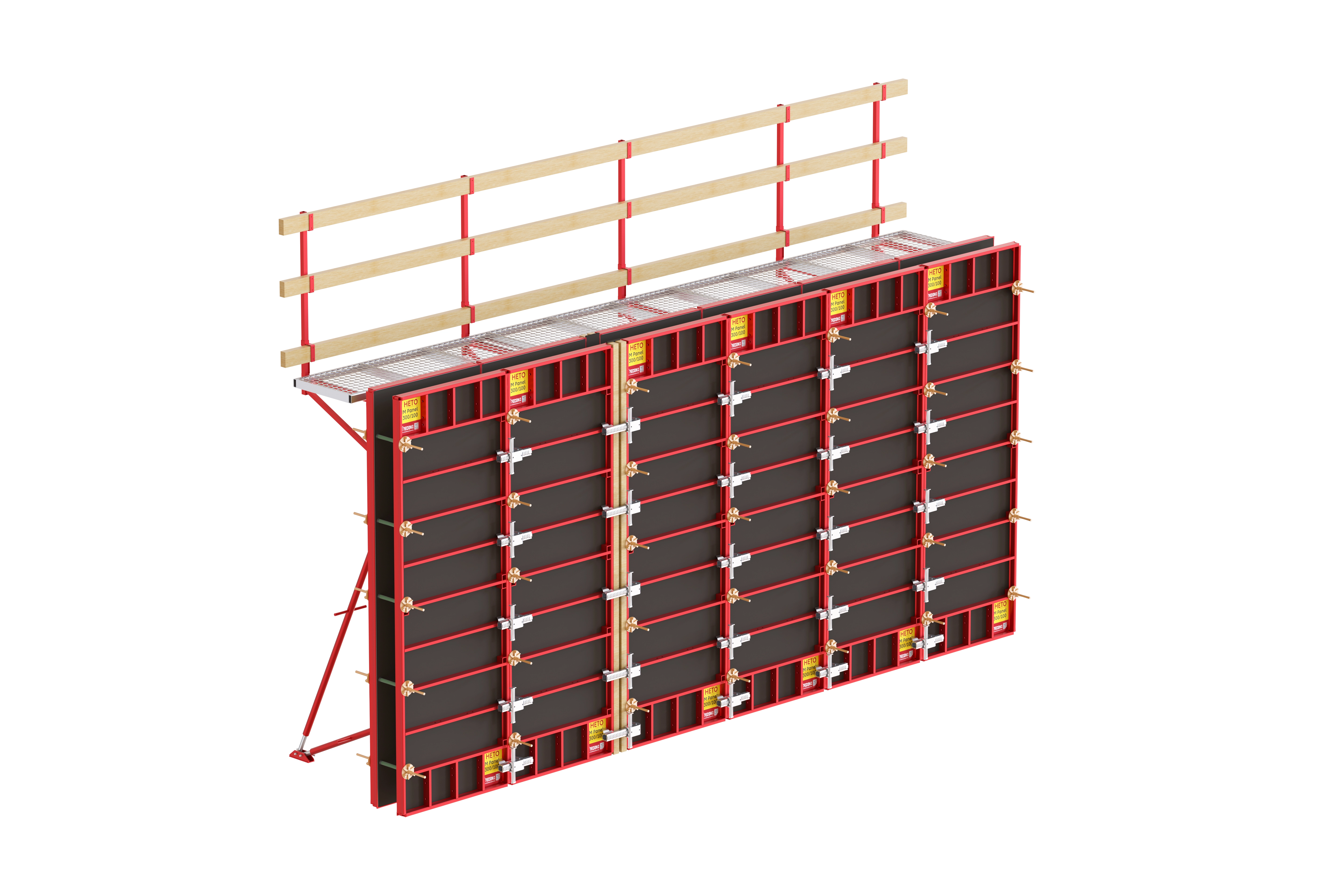

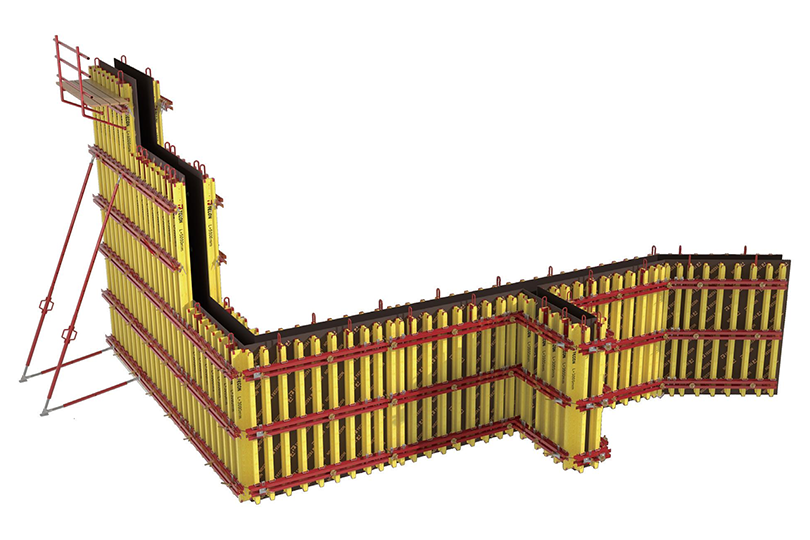

The aluminum formwork system construction technology is suitable for the construction of concrete structural walls, horizontal floors, columns, beams, climbing molds, and pipe corridors. It has significant characteristics in construction methods and is superior and innovative compared to traditional wooden and steel formwork construction technology in terms of construction period, quality, safety and civilization, and economic and environmental protection.

High strength, light weight, and a weight of only 21-25 kilograms per square meter; easy construction, simple assembly, and the formwork can be fully dismantled by manual labor, and all materials are manually vertically transmitted without relying on tower cranes and unloading platforms; high construction efficiency, and standard layer can be completed in five days.

The construction technology adopts an early disassembly formwork system, and the aluminum formwork support system does not need to build horizontal rods under normal circumstances. (The first horizontal rod needs to be built when the height is less than 3.2m-3.8m). The support head of the vertical support rod is rigidly connected with the formwork to form a portal frame between each support rod. When the formwork is removed, the support system is still maintained, and the support rods are removed after the concrete strength satisfies the requirements.

The overall appearance of the aluminum template after dismantling is good, with almost 100% pass rate in appearance quality, flatness, straightness, sectional scale, etc., which has been well verified in actual measurement data, and this cannot be compared with traditional templates such as wooden formwork.

Through engineering testing, the wall flatness of the aluminum formwork construction can reach (-3,3), which is due to the good strength, rigidity, and stability of the aluminum alloy formwork. Especially after the second kneading, the surface coating of the aluminum template is cured with double-layer solidification technology, which has high strength and corrosion resistance, greatly ensuring the quality of the concrete pouring surface. In the traditional wooden formwork, there are often phenomena such as bulging and bursting, while the aluminum alloy formwork construction can prevent such phenomena.

High load-bearing capacity, up to 30KN-40KN per square meter (the experimental load can reach 60KN); less construction waste on-site, and simple support system.

All accessories of the aluminum formwork system can be reused. After the construction is dismantled, there is no waste on-site, the support system structure is simple, and it is easy to dismantle. Therefore, the entire construction environment is safe, clean, and tidy. Moreover, the template of the next layer is directly circulated to the upper layer for construction, and the arrangement of circulating materials is convenient.

Long service life, high turnover times, and low single cost. Theoretically, it can reach more than 300 times under standard construction, and the price cost is lower than traditional wooden and bamboo formwork; high recovery value; aluminum formwork is a new green and environmentally friendly building material. Even after using it more than 100 times, its aluminum can be 100% recycled and reused without causing pollution to the environment.

In the construction of the aluminum template, only one set of formwork turnover equipment is needed, which saves construction materials. The outstanding appearance standard of the concrete reduces the amount of plastering mortar, reduces the concrete waste caused by bursting molds, and reduces the manpower and cost of finishing, which has good energy-saving and environmental benefits.

As one of the leading experts in the field of formwork and scaffolding engineering, our extensive range of off-the-shelf and customized products ensures that we can offer solutions for your construction projects, no matter the size or location. Feel free to contact us for consultation.