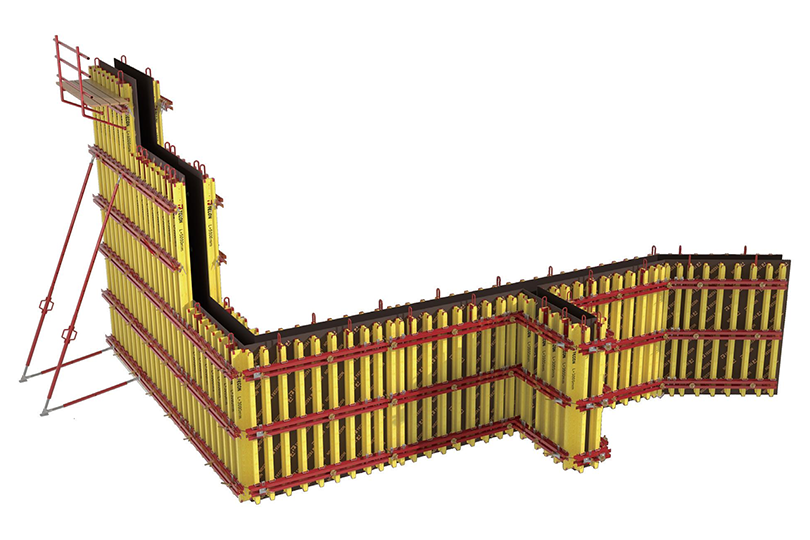

For the construction team, installation of bridge steel formwork requires ensuring sufficient strength, stiffness, and stability while also being able to reliably withstand the various construction loads specified in the formwork construction standards. Therefore, we will share the different installation methods of bridge steel formwork and their respective characteristics.

The concrete of the bridge body is poured onto the supports set up on the bridge site, and after reaching the required strength, the formwork and supports are removed.

The on-site casting method for bridge steel formwork does not require on-site prefabrication or large lifting and transportation equipment. The main reinforcing bars of the beam cannot be broken, ensuring the integrity of the bridge.

However, the use of construction formwork, such as support and bridge steel formwork, presents several disadvantages. These include a longer construction period, difficult construction quality control, stress losses caused by the shrinkage and creep of prestressed concrete beams, large consumption of support and bridge steel formwork during construction, high cost, and impacts on drainage and navigation due to the support setting. During construction, it may also be threatened by floods and drifts.

The prefabrication site is located near the prefabrication plant or the bridge location, and the prefabricated beams are constructed using a certain installation method, which comprises three parts: prefabrication, transportation, and installation of reinforced concrete or prestressed concrete simply supported beams.

The main features of this method include good quality of the components, which helps ensure the quality and dimensional accuracy of the components and uses mechanized construction. The upper and lower structures can operate in parallel, shortening the construction period of the site. It can effectively utilize labor resources, thereby reducing project costs. Due to its fast construction speed, it can be used in emergency construction projects. After prefabrication, there is a certain period before installation, during which the deformation caused by the shrinkage and creep of concrete can be reduced.

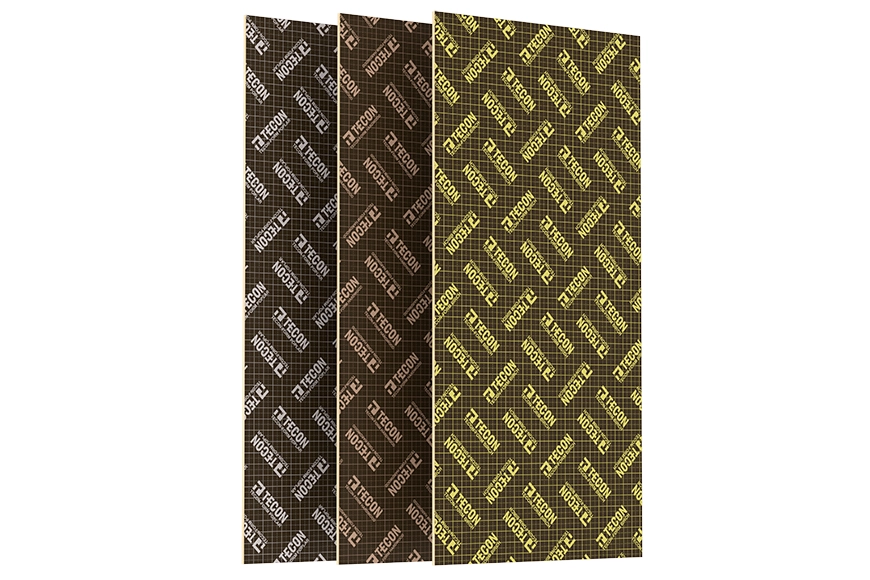

As one of the leading experts in formwork and scaffolding engineering, our company offers a wide range of off-the-shelf and customized products to ensure that we can provide solutions for your construction projects, no matter the size or location.

With the professional knowledge of our research and development team members from our formwork company, we are available on-site to provide you with assistance whenever necessary, and our solutions are always cost-effective. From the first contact to the completion of construction, we are always there to support you. Feel free to inquire.