As a new type of formwork, aluminum alloy formwork has many advantages, but there are still some shortcomings that need to be improved. So what are the common problems of aluminum alloy formwork in the construction industry? How to deal with it effectively?

This kind of problem is also a common problem in the use of aluminum alloy formwork. When it was first used, the surface of the concrete often showed bubbles, which directly affected the quality of the factory.

After the concrete is poured, the surface will show oxidation corrosion, which will cause the problem of bubbles. However, after the aluminum alloy formwork has been used several times, this problem will gradually decrease, because its surface has already formed. A protective film.

It directly prevents the contact between the concrete and the aluminum alloy formwork, so for the phenomenon of air bubbles, it is now possible to brush a layer of cement on the surface of the new aluminum alloy formwork, let it oxidize first, and then remove the surface dirt to achieve the pre-oxidized surface. effect.

When the concrete pouring is completed, the structural layer simply shows errors. Generally, this situation is due to the accumulation of errors caused by the lack of construction according to the elevation during the pouring, and then the elevation control line has been re-measured several times. The first floor is set with many control points, and when pouring concrete, the construction is carried out according to the marked height.

If the aluminium formwork is used too many times, deformation will inevitably occur. At this time, it is necessary to observe the bearing capacity and hardness of the aluminum alloy formwork, whether it can meet the support operation, and strictly control the height during pouring, and it is strictly forbidden to vibrate vigorously to cause aluminum The deformation of the alloy formwork, resulting in the deformation of the poured concrete.

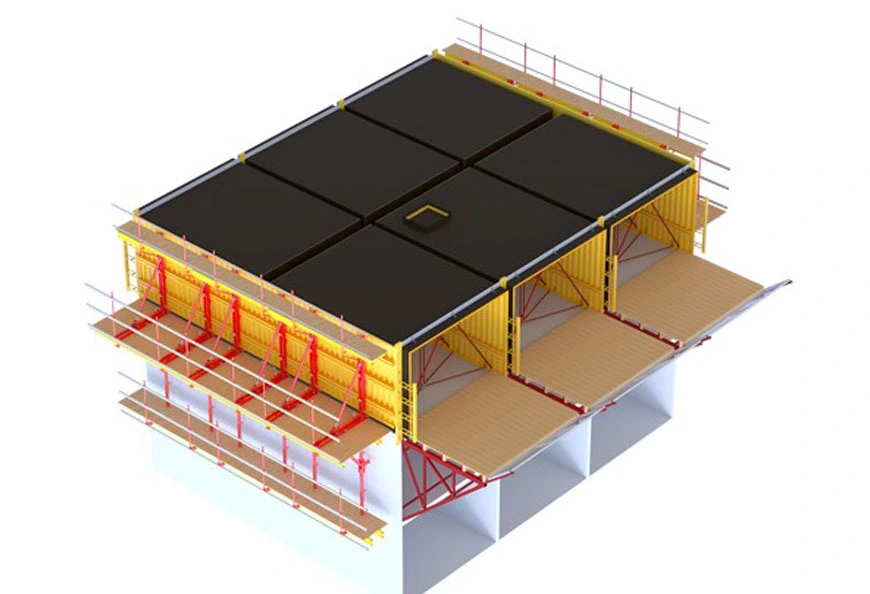

As one of the leading experts in formwork and scaffolding engineering, our wide range of off-the-shelf and bespoke products ensures that we can provide a solution for your construction project, no matter the size or location.

With the expertise of our R&D team, our technical team members on-site to assist you when necessary, and knowing that our solutions are always cost-effective, you can rest assured that from first contact to construction completion, we are all Always there to support you. Welcome to consult.