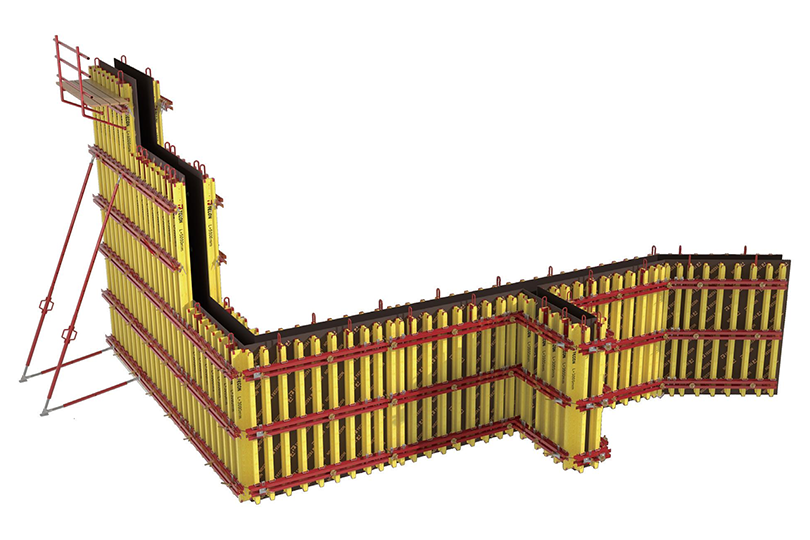

Wooden building formwork is a kind of temporary supporting structure, which is made according to design requirements so that the concrete structure and components are formed according to the specified position and geometrical size, keep their correct position and bear the weight of the building formwork and the external load acting on it.

1. Glue

The key to the service life of wooden building formwork lies in the variety and content of glue. The production of international building formwork requires layer-by-layer glue. The glue requires the use of waterproof phenolic resin glue for the panel, and melamine glue for the core board, with a glue content of 0.45kg. Reducing the amount of glue, changing the variety of glue, or using interlayer glue can reduce production costs, but these products are non-national standard products, the formwork is easy to degummed, and the quality is not guaranteed.

2. Core board

High-quality boards will choose high-quality raw materials. The quality of log veneers directly affects the internal density and bonding strength of the boards. The high-quality building formwork adopts the first-level core board to ensure that the inner layers of the formwork are tightly combined without voids, which is the basic guarantee for a long service life.

3. Pressure

The crisscrossing core board is pressed by high temperature and high pressure, and the glue can be cured to produce the adhesive force and strength. The high-quality wooden formwork for building uses a pressure of more than 230MPA during the hot pressing process to ensure the tight bonding between the core layer and the layer. Any processing technology that reduces the pressure, although the thickness of the formwork reaches the standard, actually reduces the quality of the formwork itself, seriously affecting the service life and turnover of the formwork, and is a substandard product.

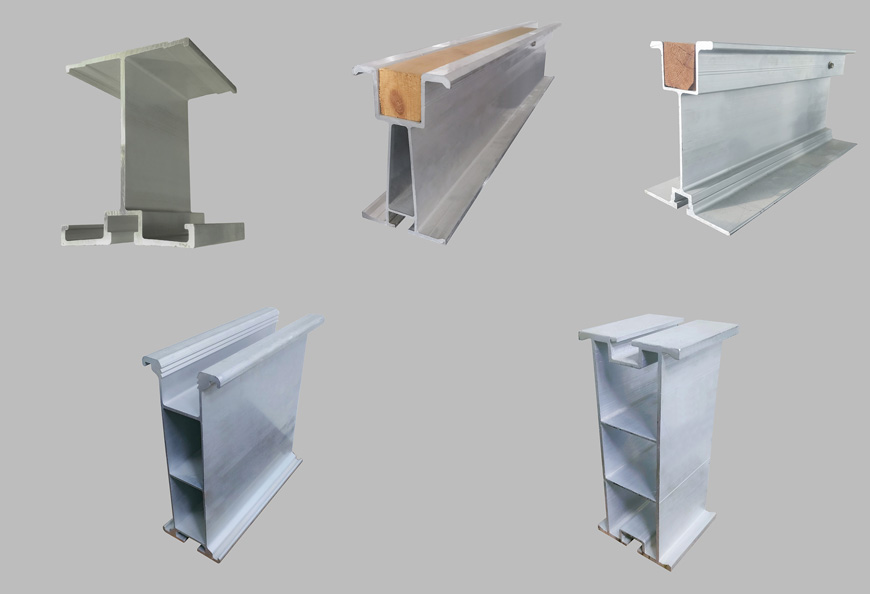

4. Panel

The surface of the high-grade wooden building formwork is as bright as a mirror, and the whole body is shiny, which is mainly affected by two aspects. One is the variety of glue used on the panel. The high-quality wooden building formwork uses unknotted or few-knotted imported radiata pine as the surface. The whole sheet is flexible and does not lose strength. It is the basic condition for the smooth surface of the board. The second is the material used in the panel. Using a certain concentration of phenolic resin glue, after hot pressing, the phenolic glue flows on the surface of the board to form a waterproof and smooth film, which has achieved the effect of easy demolding. The local pine surface bark has large knots, rough wood chips, and many dead knots. Although the cost is low, the board surface is rough and colorless, and it is difficult to demold. This type of formwork is not superior.

5. Moisture

Internationally, the moisture content of wooden building formwork is required to be between 8-10%, because the environmental moisture of the formwork is generally around 8%. Good control of the moisture can effectively increase the service life of the formwork, because the moisture content is close to the environment, and the formwork will not absorb water and expand. Any production process that speeds up the production cycle and reduces the drying time of the core board is reducing the quality of the formwork. The moisture should not be too high or too low. In order to save materials and increase the effect, it is not advisable to prepare a large amount of glue at one time.

As a professional formwork supplier, we specialize in providing the most reliable and highest quality wooden building formwork. We offer competitive prices and unmatched customer service. Our experienced team can help you find the perfect solution for your project. If you are looking for a reliable and cost-effective solution for your formwork needs, please do not hesitate to get in touch with us for a free consultation. We look forward to hearing from you!