When choosing a bridge steel formwork, what should we pay attention to? What standards should we adhere to when using the bridge steel formwork for allocating reinforcement? Many people may not be very familiar with these two questions, so let's take a look.

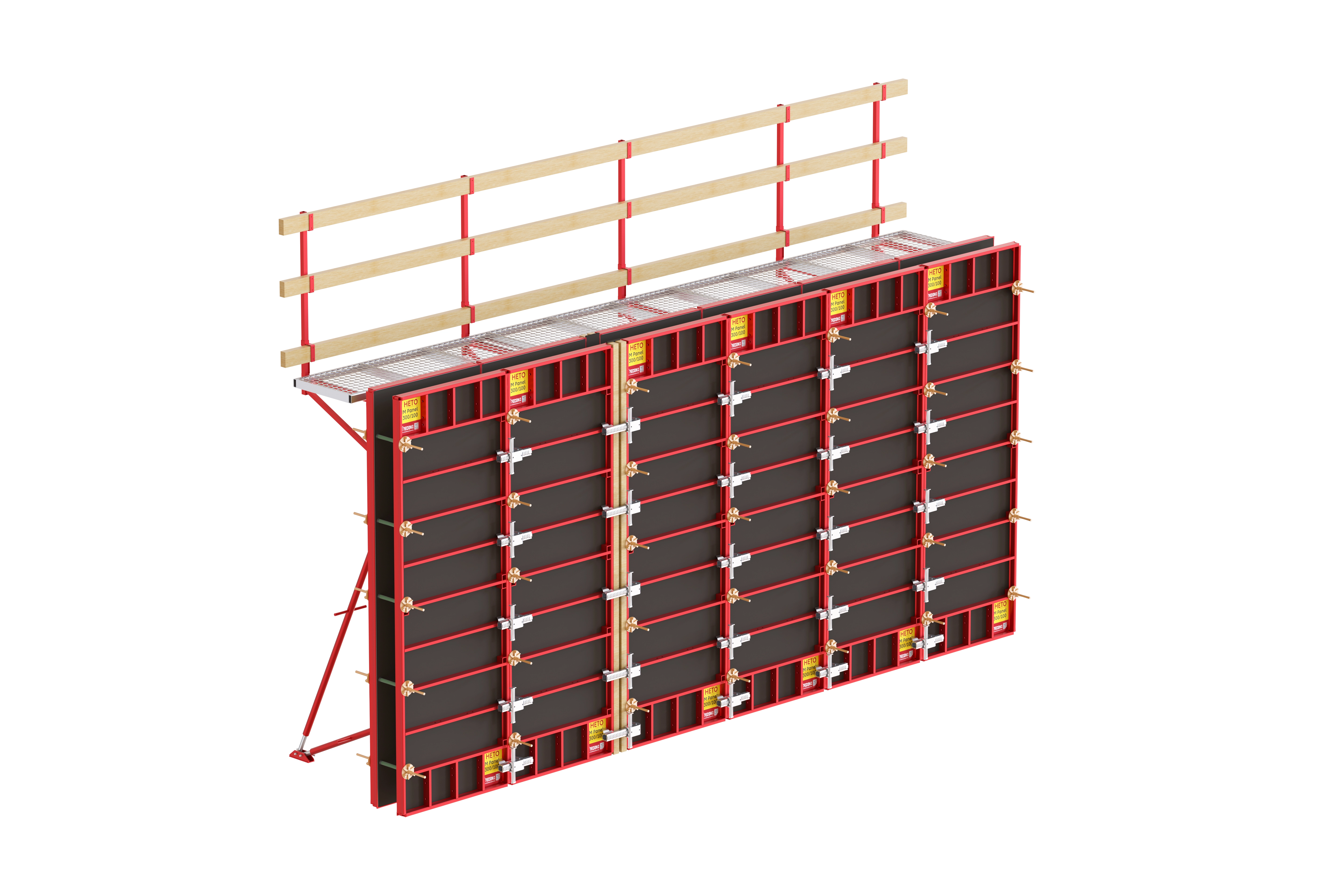

The formwork for bridges, made of steel, must ensure the correctness of the component shape, size, and relative position.

The formwork should have sufficient strength, rigidity and stability, and be able to withstand the weight and lateral pressure of newly poured concrete, as well as various construction loads.

The bridge steel formwork should be structurally simple, easy to assemble and disassemble, not interfere with steel reinforcement binding, and ensure that there is no slurry leakage during concrete pouring.

The configured formwork should prioritize universal and large blocks, reduce the number of block types and wooden parts. For the formwork with tension bolts, 55mmx100mm polished square wood can be used instead of drilling through the steel formwork to reduce loss.

The longitudinal splicing of formwork should be arranged staggered to increase the overall rigidity of the formwork.

The support system of the formwork should be arranged according to the load of the formwork and the rigidity of the components.

The design of the formwork should draw a formwork diagram, indicating the position, specifications, models, and quantity of the steel formwork. For pre-assembled large formworks, their boundary lines should be marked. The positions of the embedded bodies and reserved holes should be indicated on the formwork diagram and the fixation method should be noted.

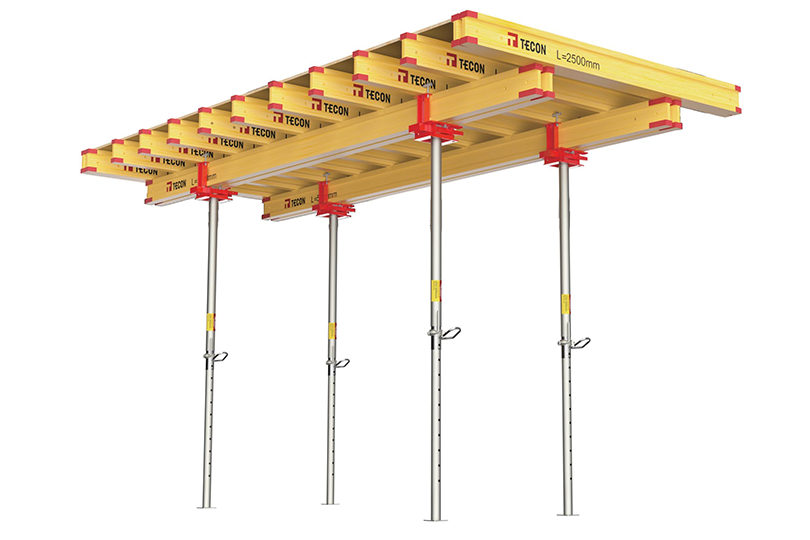

When allocating reinforcement with bridge steel formwork, the strength, rigidity, and stability should be ensured to ensure that the steel formwork can bear the weight and construction load of concrete pouring.

Before allocating reinforcement with steel formwork, a corresponding allocation diagram should be planned, and the number and orientation of the steel formwork should be accurately marked.

When allocating the bridge steel formwork, try to select larger plates and ensure that the plate steel formwork is of a general purpose. The bolt used to fix the steel formwork should be selected relatively to reduce the wear and tear during drilling.

When allocating reinforcement with bridge steel formwork, the shape, standard, and correctness of the component should be ensured.

When allocating reinforcement with bridge steel formwork, the structure should be simple and easy to transfer, and ensure that there is no slurry leakage when the steel formwork is used for pouring.

If the option of a long route splicing is chosen when allocating the steel formwork, it is best to arrange it in a staggered manner, which can enhance the overall rigidity of the steel formwork.

As one of the leading experts in the field of formwork and scaffolding engineering, TECON relies on the professional knowledge of our R&D team. Our technical team members will provide on-site assistance if necessary, and our solutions always have cost-effectiveness. You can rest assured that we will support you from the first contact to the completion of construction. Welcome to inquire.