Bridge steel formwork can easily deform if not properly handled during use and processing. So, what should we do when the bridge steel formwork becomes deformed?

When pouring concrete, it should be evenly symmetrical without leaks. The pouring height should be strictly controlled, especially on both sides of door and window openings in building formwork. This ensures that the concrete is compacted and prevents excessive compaction from causing deformation of the bridge steel formwork.

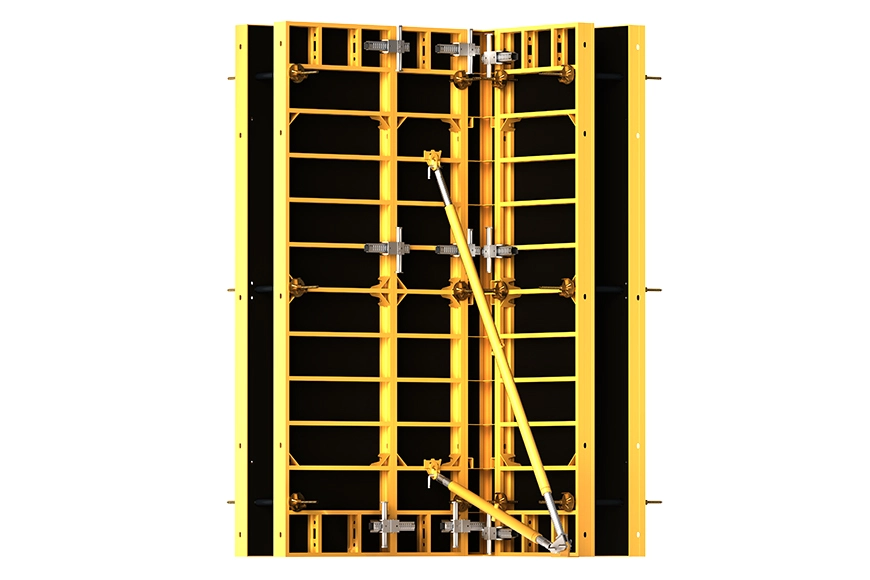

When designing the building formwork and support system, the primary consideration should be given to the product's own weight, construction loads, and the weight of concrete produced during pouring, ensuring adequate carrying capacity and stability of the building formwork support.

When constructing with wooden or plywood building formwork, it should be promptly filled with concrete after passing inspection to prevent deformation caused by long-term exposure to sunlight or rain. Similarly, the use of conform concrete formwork ensures proper stability and resilience throughout the construction process.

For reinforced concrete beams and slabs spanning at least 4 meters, the bridge building formwork must be arched according to the design requirements. When specific design requirements are not available, the arching height should be 3/1000 of the span.

When using a car for transportation, the formwork that exceeds the height of the side panels of the carriage must be tied and fixed with ropes. It is prohibited to carry people on either the carriage or bridge steel formwork.

During transportation, drivers must abide by traffic regulations and avoid speeding.

The bridge steel formwork transported to the construction site must be neatly stacked with square blocks at the bottom. The stacking height should not be too high to prevent falling.

It is prohibited to stack the bridge steel formwork along the edge. It must be ensured to be stable when stacked on scaffolds or construction platforms to avoid slipping. The stacking weight must not exceed the limit and should not affect traffic.

When lifting the bridge steel formwork into the warehouse, it must be directed and hooked by a lifting operator. The steel formwork must be tightly fastened with a traction rope below and not lifted by a single rope. It is also forbidden to clamp other objects inside the formwork. All kinds of fittings must be put into tool bags. When lifting, a lifting basket must be used.

With our professional R&D team and experienced technical team members from our formwork company, we will provide you with help on-site when necessary. Our solutions always have cost-effectiveness, and you can rest assured that we are always there to support you, from the first contact to the completion of the construction. Welcome to inquire.