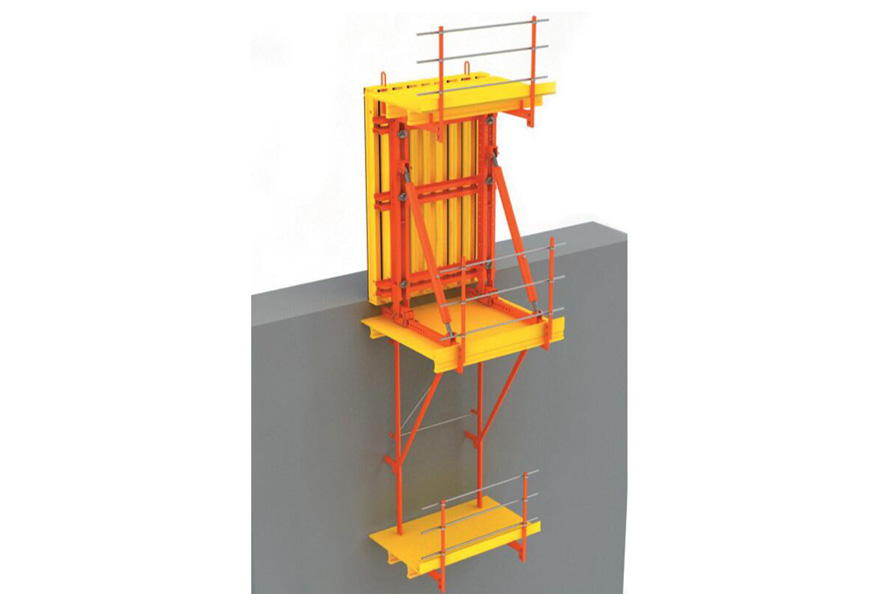

The self-propelled hydraulic integral template is a technological equipment that drives the template to move through a walking car after the ordinary traditional template is assembled. The car is equipped with longitudinal and vertical hydraulic cylinders. After the template reaches the beam base, the verticality and plane position of the template can be adjusted through the cylinders to meet the requirements of use.

The main advantages are that the hydraulic moving integral template is easy to assemble and adjust, with accurate positioning and tight seams; the use of the hydraulic moving integral template not only improves the efficiency of template installation, reduces the risk of lifting operations, and reduces the labor intensity of workers, but also increases the utilization rate of the template.

Compared with the traditional lifting side formwork, the entire system can enter the construction state after one installation and commissioning. The installation, disassembly, and longitudinal movement of the entire system template are completed with the help of a self-propelled hydraulic car system under the side template system. The template system does not need to rely on lifting equipment throughout the construction process, greatly reducing safety risks.

Compared with the traditional hydraulic T-beam formwork, the addition of vertical adjustment and longitudinal beam movement functions in the beam formwork greatly enhances its functionality. This allows for increased utilization of the side template system by 2-3 times, resulting in higher efficiency and productivity in construction projects.

The self-propelled hydraulic integral template is composed of a template, reinforcement device, walking mechanism, hydraulic system, adjustment support system, etc. The template is composed of a side formwork, toothed plate, retaining wall, end formwork, etc. The walking mechanism is composed of four cars, which are fixed with the T-beam side formwork after reinforcement, convenient for disassembly and assembly; the walking track of the car is fixed on the concrete ground by an inverted 8-shaped groove, parallel to the beam base.

The walking wheel and driving motor of the car are driven by gears. The diameter of the walking wheel is 20cm, and the width of the wheel slot is 12cm, which matches the walking track. Each set of template system is equipped with two beam bases.

After the concrete of a beam base is poured and the template is removed, it walks along the track to the next beam base for the construction of the next T-beam. The hydraulic system mainly consists of an operation pump station, cylinders, and oil pipes. The cylinder is divided into a horizontal cylinder and a vertical cylinder.

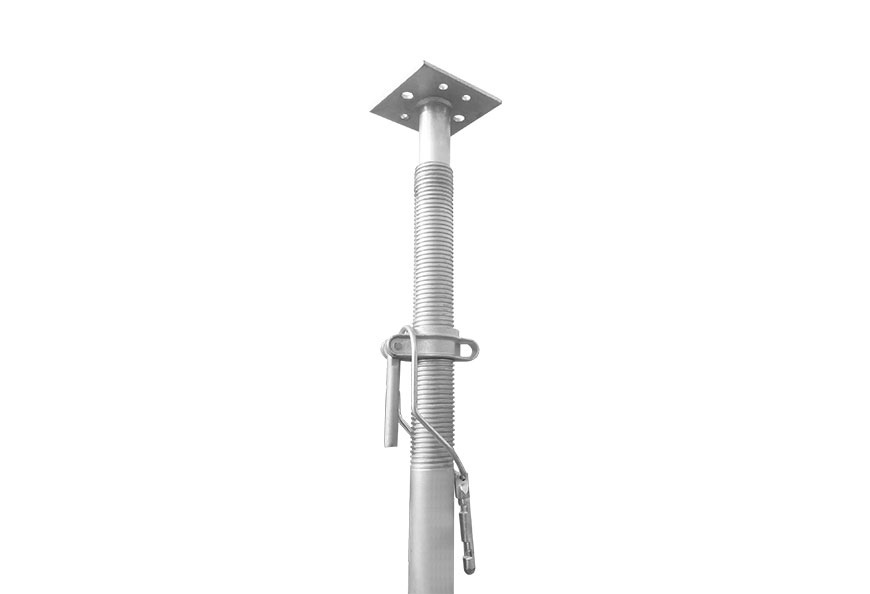

The stroke of the horizontal cylinder is 1.5m. It is connected with the steel bar groove steel at the bottom of the T-beam side formwork, driving the horizontal movement and assembly and disassembly of the template. The vertical cylinder is connected with the reinforcement groove steel at the middle of the rear of the template, with a stroke of 20cm. After the hydraulic T-beam formwork is in place horizontally, the up and down adjustment and verticality adjustment are carried out to meet the requirements of use. The adjustment support system mainly improves the stress situation of the side formwork during the concrete pouring process, ensuring the reliability and stability of the side formwork. After the template is in place, it needs to be reinforced up and down to prevent template expansion, running, and floating mold.

As one of the leading experts in the field of formwork and scaffolding engineering, our extensive range of ready-made and custom products ensure that we can provide solutions to your construction projects, no matter how big or small or where they are located. Feel free to inquire.