In order to ensure the construction quality of the circular column formwork, it is necessary to understand some precautions for shaping the circular column formwork to avoid similar things.

It is strictly forbidden to use open flames and electric welding during the installation of the circular column formwork. The wooden circular column formwork is made of large-format plywood, so that the circular column formwork has fewer joints and fewer joints; and the birch poplar material ensures the high strength and toughness of the formwork. Scaffolding should be erected firmly. Occupy large-scale machinery and equipment, and the cylinder molding effect is not good and so on. When removing the mold, no one is allowed to stand below; the removed connectors, etc. are thrown downward from a high place.

In the construction of cast-in-place floor slabs, the connection between the floor slabs, beams and walls must be handled well. The processing method of the connection between the floor slab and the beam is that when the beam is slid, the upper edge of the beam leaves the thickness of the floor slab without pouring concrete, and pours it at the same time when the floor slab is constructed. The surface of the cylindrical template is smooth and wear-resistant, and does not deform at high temperature. The treatment method of the connection between the floor and the wall: The wooden box can be pre-buried on the wall to leave holes at intervals. When the floor is to be constructed, the floor wood bars are inserted into the holes, and then concrete is poured.

Wooden circular column formwork green building engineering construction is an inevitable trend!

Because China is in the historical period of rapid development of industrialization, urbanization and new rural construction, the wooden circular column formwork, circular column formwork and special-shaped formwork produced are sold well at home and abroad, which deeply promotes building energy conservation and accelerates the development of green buildings, ushering in a rare historical opportunity. Simple and safe green buildings have gradually become the main theme of the market. Rise evenly to the upper floor and repeat the above procedure.

Climbing frame up: After the second layer of concrete is poured, the through-hole screw rods of the circular column formwork and the inner form cannot be removed. Remove the hand-pulled upside-down chain, hang it on the circular column formwork boom, put down the small hook of the upside-down chain, and tie it to the climbing frame with a wood wire rope. After it is secure, loosen the bolt at the lower end of the climbing frame, pull the upside-down chain, and lift the climbing frame to the upper floor. Floor, and then re-anchor the climbing frame to the shear wall.

Clear water: It is used for construction of circular column formwork in winter. The surface of wooden circular column formwork is smooth and clean, without joints, easy to demould, easy to clean and maintain, no release agent is required, the surface of the formwork after use does not stick to cement, and the formwork does not need to be cleaned. And its thermal insulation performance is better, and winter construction relies on it.

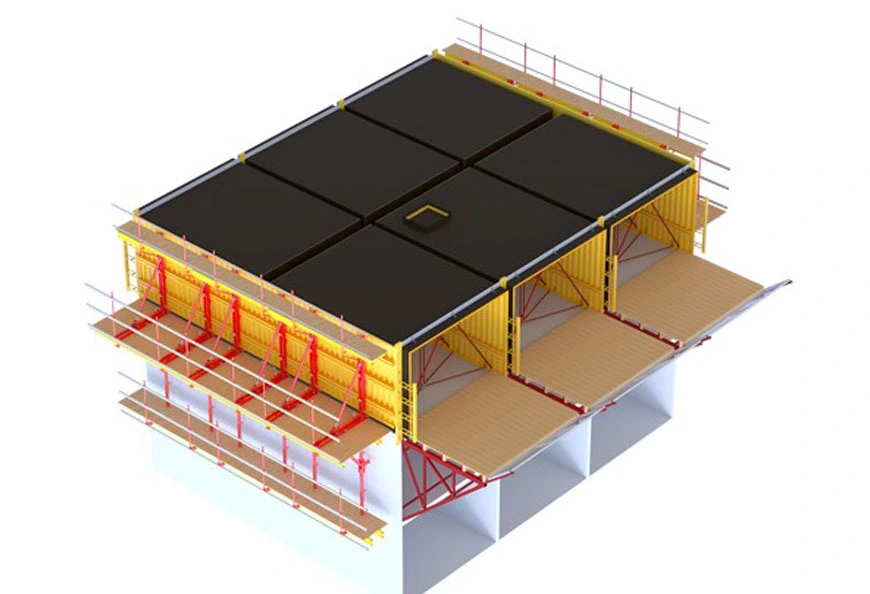

During the construction of the formwork project, it must be assembled in sequence according to the plate design and construction instructions. The elevation and plane size must be accurately controlled, the accessories must be firmly assembled, and the embedded parts and reserved holes must be positioned accurately and firmly installed. The bottom surface of the column formwork must be leveled. After the pre-assembled wall formwork is in place, the lower end should be flat and close to the positioning datum, and the formwork on both sides should be adjusted and fixed with diagonal braces.

With the increase of high-rise buildings year by year, the construction of large formwork for shear walls is becoming more and more extensive, for enterprises with a certain amount of formwork.