In fact, since the building formwork has been created, it has been continuously iteratively upgraded. From the initial steel formwork to the later wood formwork, bamboo and plywood, to assembly formwork, aluminum-plastic formwork, these continuous product upgrades are in line with the times.

Every product has been facing challenges since its appearance. If it cannot meet the needs of the market, it will be gradually eliminated. For example, the human housing used straw and soil from the beginning, then bamboo and wood, and then appeared again. Building houses with bricks, to the current cast-in-place concrete and even some glass and steel structure houses, this is the iterative upgrade of the product in line with the development of the times.

The prefabricated formwork in building construction has also been updated and upgraded for several generations before it has gradually evolved into a common polymer composite building formwork on the market. The solid plastic formwork of PVC material that was often used in the past cannot meet the market demand due to its performance. The formwork is relatively brittle, It is easy to break and deform, and is greatly affected by temperature changes, and has now been gradually eliminated by the market.

It is reported that after continuous experiments and modification, the prefabricated building formwork has become a mature and popular product in the market. The turnover of this assembly formwork can reach more than 100 times, and it can be planed, nailed and sawed, which is extremely convenient to use. It can also adapt to various temperature environments, and can be used in the range of -20 ° C ~ 120 ° C without deformation.

It is reported that another advantage of the prefabricated building formwork is that it can be fully recycled, whether it is the whole formwork after use or the cut scraps can all be recycled, which is also one of the important reasons why polymer composite formwork can save material costs for construction units.

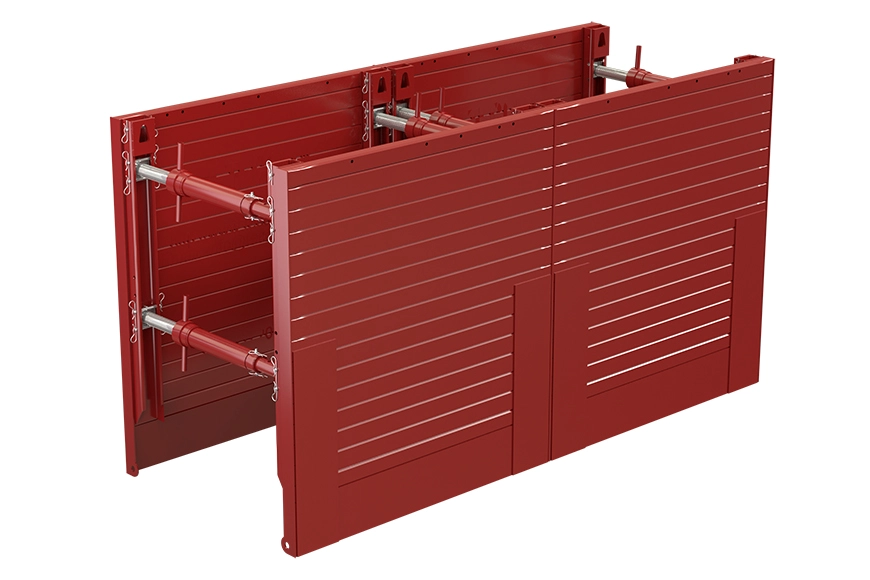

As one of the leading experts in formwork and well-known scaffolding manufacturers in China, our wide range of off-the-shelf and custom products ensures that we can provide a solution for your construction project, no matter the size or location.

With the expertise of our R&D team, our technical team members are there to assist you when necessary, knowing that our solutions are always cost-effective, you can rest assured that from first contact to construction completion, we are always there to support you. Welcome to consult.