Props for shuttering have been developed in response to the demands of construction work and are an essential measure and equipment in construction operations.

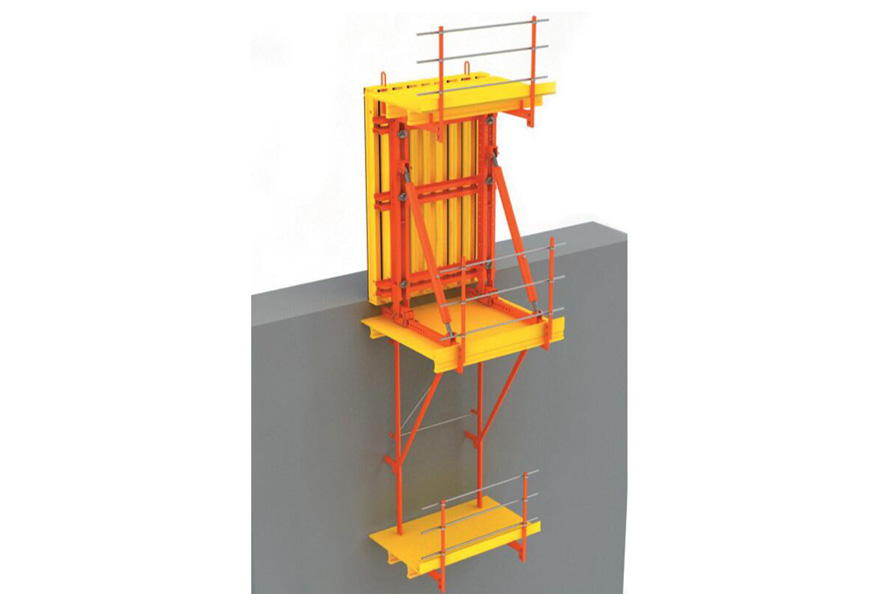

Setting Up the Props and Installing the Formwork

The installation of the scaffold must be done under the unified direction of the foreman and supervised by the safety officer, strictly following the prescribed procedures: marking the layout according to the scaffold design, laying down the base plates, and determining the positions of the vertical posts. For in-situ reinforced concrete beams and slabs with spans of ≥4 meters, the formwork crown height should be between 1/1000 and 3/1000 of the beam or slab span. The crown height should not reduce the cross-sectional height of the components.

Construction Procedure

Lay down the base plates → Erect vertical posts → Install ground braces → Horizontal braces → U-type supports → Main beams → Secondary beams → Multi-layer boards.

Strictly Follow Operating Regulations: When installing the props for shuttering, ensure that all steps follow safety operating procedures to prevent accidents.

Regular Inspection and Calibration: Even seemingly sturdy props for shuttering require regular inspections and necessary calibration to ensure they remain in optimal working condition.

Safety: The design of props for shuttering takes safety into account, such as the self-locking function of the bowl-lock scaffolding, ensuring reliable connections.

Efficiency: Modern props for shuttering systems, such as the pin-type formwork scaffolding, feature quick installation and disassembly, significantly improving construction efficiency.

Economy: Some systems, such as the plug-in keyway-type steel pipe props, are widely used in large-scale construction projects due to their low cost and durability, helping to save costs.