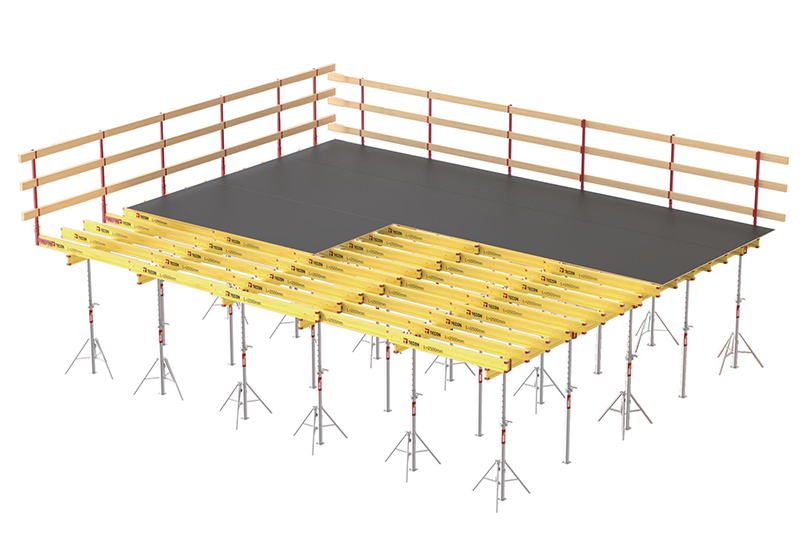

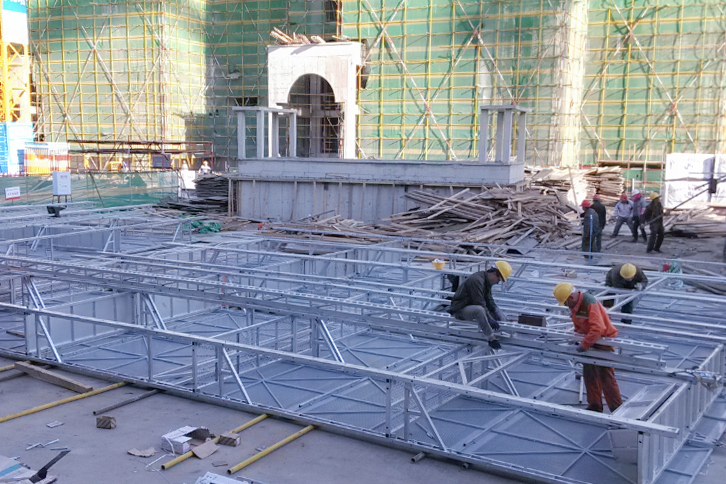

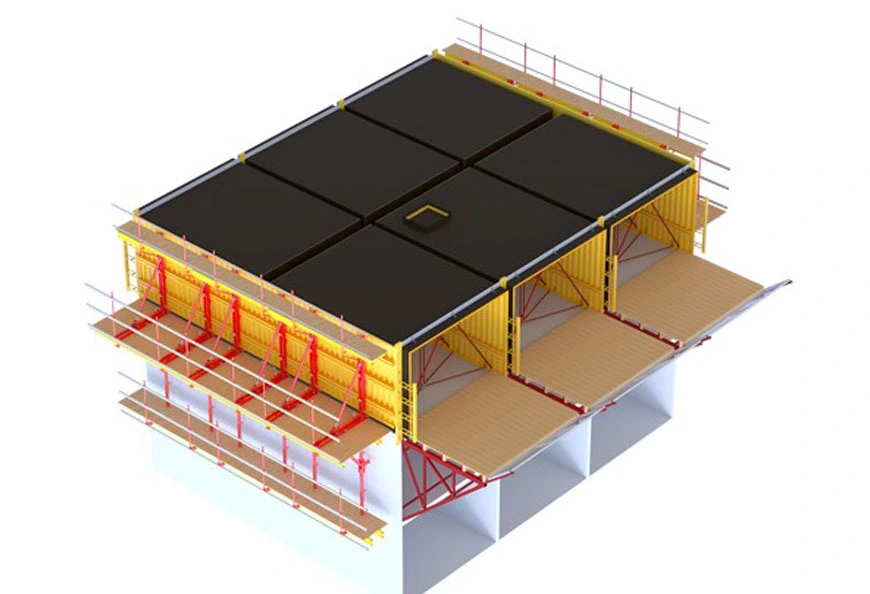

The role of formworks is to shape concrete components according to their design shape and size. Therefore, the rationality of material selection and construction, as well as the quality and installation of the formworks, directly affect the quality, duration, and cost of concrete structural engineering. However, in addition to these factors, if sufficient protection measures are not taken in rainy weather during construction, it will also affect the shaping of concrete components.

Lightning protection measures should be taken for the transformer of the temporary power supply.

After entering the rainy season, cover and protect the tied beam rebar to prevent rusting from rain before concrete construction.

Keep in close contact with the meteorological department, grasp the weather changes, arrange construction, and prevent sudden weather changes to be prepared in advance.

Double-sloped cover plates and rain caps should be added to the construction distribution box to prevent rainwater from flowing into the box.

Cement and other raw materials should be covered and kept dry, with good ventilation.

Anti-freezing measures should be taken for the water intake pipe.

Formworks are an important part of the shaping of concrete components. Therefore, concrete formwork system should not only take all safety measures during construction but also pay close attention to protection measures during the rainy season.

During the winter season, due to the colder temperature, when constructing bridge formworks, in addition to conducting daily quality inspections, the environmental temperatures during concrete pouring and curing need to be checked, and the following inspections need to be carried out:

When concrete is poured and cured in winter, in addition to leaving standard curing specimens, the same number of test blocks that are conditionally cured under the same structure should also be made.

The heating and curing methods and duration of concrete should be recorded separately in the records of the concrete engineering construction and temperature checks.

The temperature of the water used for heating the concrete.

The interior and exterior environmental temperatures during concrete curing, measured at regular intervals of four times per day and night.

The temperature of the aggregates and mixing water when loaded into the mixer, the temperature when the concrete is poured from the mixer, and the temperature during casting, should be checked at least three times per work shift.

These inspections are all very important and related to the later use effect. Therefore, it is hoped that everyone will be strictly careful. Our company is one of the professional formwork manufacturers specializing in bridge formworks, with guaranteed product quality and affordable prices, and we welcome inquiries.