Bridge formwork, as the name suggests, is a steel formwork applied to bridge projects, and the following five regulations should also be followed when this bridge formwork is supported and installed:

1. Assemble in sequence according to the design of the bridge formwork to ensure the overall stability of the formwork system.

2. The accessories must be firmly installed, the supporting surface of the support and the diagonal brace should be flat and solid, and there should be enough pressure area. The embedded parts and the reserved holes must be positioned accurately and installed firmly.

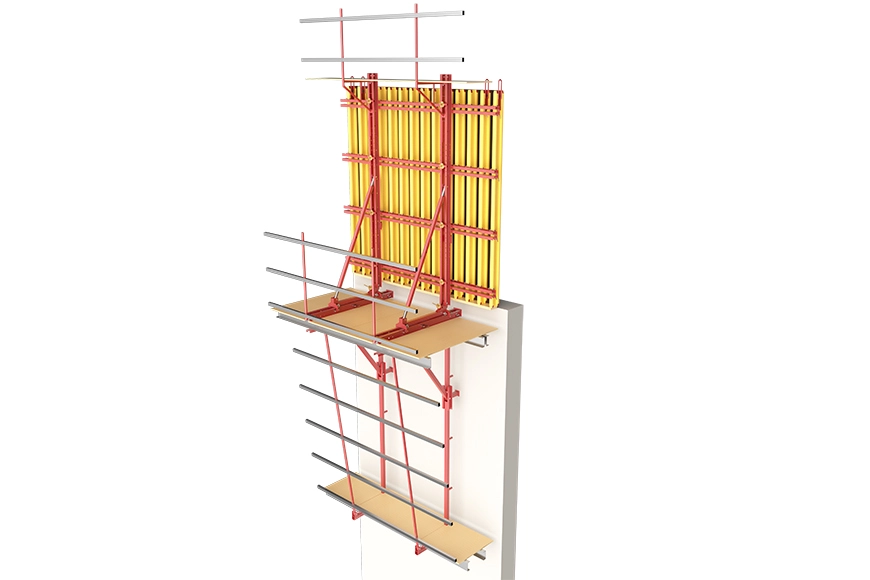

3. The bottom surface of the wall and column formwork should be leveled, the lower end should be close to the pre-made positioning datum, and there should be reliable support points when continuing to install the steel formwork on the wall and column, and its straightness should be corrected.

4. The base bridge formwork must be firmly supported to prevent deformation, and a dunnage should be added to the bottom of the oblique support of the side formwork.

5. After the pre-assembled bridge formwork is hoisted into place, the lower end should be flat and close to the positioning datum, and the verticality of the formwork on both sides should be adjusted and fixed with diagonal braces. The horizontal bracing and scissor bracing provided by the pillar shall be arranged according to the structure and overall stability; and the upper and lower floor slabs of the multi-layered pillar shall have the bearing capacity to bear the load of the upper layer or additional support shall be provided, and the column of the lower bracket shall be laid backing plate.

The optimization of the number of bridge shuttering is to improve the versatility of shaped steel formwork bridge construction, reduce the exclusivity (specificity) of steel bridge formwork construction, increase the turnover and frequency of bridge formwork, and reduce costs.

As mentioned above, after the number of configuration sets of the bridge formwork for the sub-project is determined, the size of the bridge formwork block should be focused on to meet the general requirements of the construction steel bridge formwork and reduce the cost.

Bridge template optimization steps: earnestly count and check the number of sub-projects and structural dimensions; secondly, compare the structural height, length, width, and yin and yang angle structure dimensions of a single cap, pier (body) column, and cast-in-place beam, and seek from the perspective of mathematical statistics. Solution: Use the equal difference balance method, the common multiple method, and the comprehensive method to determine the block method and production quantity of the bridge formwork.

The arithmetic balance method means that there is an arithmetic sequence in a certain mathematical sequence in the structural dimensions such as length, height and width of a single sub-project. In the process of making the finalized bridge template, the bridge template can be divided into blocks according to the arithmetic sequence. The difference part is solved according to the individual customized proprietary bridge template.

This method is generally used to solve the problem of bridge formwork segmenting within the height range. Generally, considering the aesthetic symmetry of the construction bridge formwork joints, the balance-adjusted bridge formwork is generally placed at the bottom for construction.