1. The formwork and wooden squares used on the same working surface must ensure the same thickness. Beams with a height of less than 600 are reinforced and fixed with U-shaped square wooden hoops, and the spacing should not be greater than 600mm.

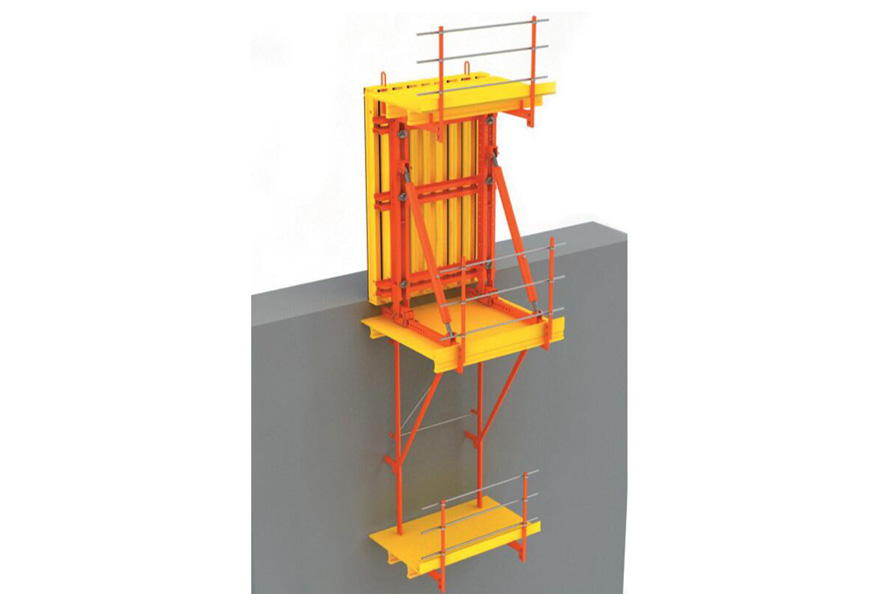

2. Beams with a height of more than 600mm should be set with through-the-wall opposite-pulling screws according to the construction plan to prevent bulging. Both sides of the beams can be fixed in the form of square wood with fasteners.

3. The beam bottom elevation must be accurate, and the elevation review should be carried out after the beam bottom plate is laid.

1. According to the length of the demolished wall and the accumulation of various loads on the upper part of the wall, determine the cross-sectional size of the beam, and then calculate its reinforcement.

2. On both sides of the wall to be demolished, set steel pipe support columns, add beams, and add pads below to support the floor on the wall to maintain its original stability, and add steel wedges to hold it tight. The section and spacing of the support columns are determined by load calculation. The fulcrum position is within the longest range at 100 mm from the end of the board (top layer of single or multiple layers). For multi-layer or bottom-level conversion beams, the location of the pouring hole is generally less than 2 meters, and the pouring hole can be on the upper side.

3. In the case of ensuring that the column is firm and stable, remove the wall. At the same time, the lower wall of the beam should be removed according to the section size of the beam and the length of the support, and the debris should be removed. In order to prevent the concrete from the original joint of the slab from falling, steel supports can be added at a distance of not more than 1.5 meters, and within the beam concrete pouring range, after the girder formwork is supported, the beam concrete is poured from one end or both ends along the floor along the floor. After completion, the standing time should not exceed the length of the early setting time of the concrete. The spacing is about 1 meter, and a concrete pouring hole with a diameter of about 150 mm is opened.

4. The bottom form of the beam can be omitted. The bottom form can be used to add an isolation layer on the removed masonry, then bind the steel bars of the beam, and finally support the side form. The formwork must be firm to meet the construction and safety needs of the beam section design size.

5. Concrete is poured into the beam from the pouring hole on the floor slab, starting from one end of the beam, and when pouring into the second hole, the first hole shall prevail. until the entire beam is filled with concrete.

6. When the concrete strength reaches 100% of the standard value of the design strength grade, the beam formwork can be removed.